Flowline LU78 EchoSwitch User Manual

Page 26

26 of 34

MN300282

Rev A

INSTALLATION

Step Seven

The EchoSwitch® should always be mounted perpendicular to the liquid surface and installed using the

provided Viton® mounting gasket. Make sure that the fitting and transmitter threads are not damaged or

worn. Always hand‐tighten the transmitter within the fitting. Perform an installed leak test under normal

process conditions prior to system start up. Note: The preferred mounting fitting for the LU77 Series is the

LM52‐1400 (2” thread x 1” thread) reducer bushing.

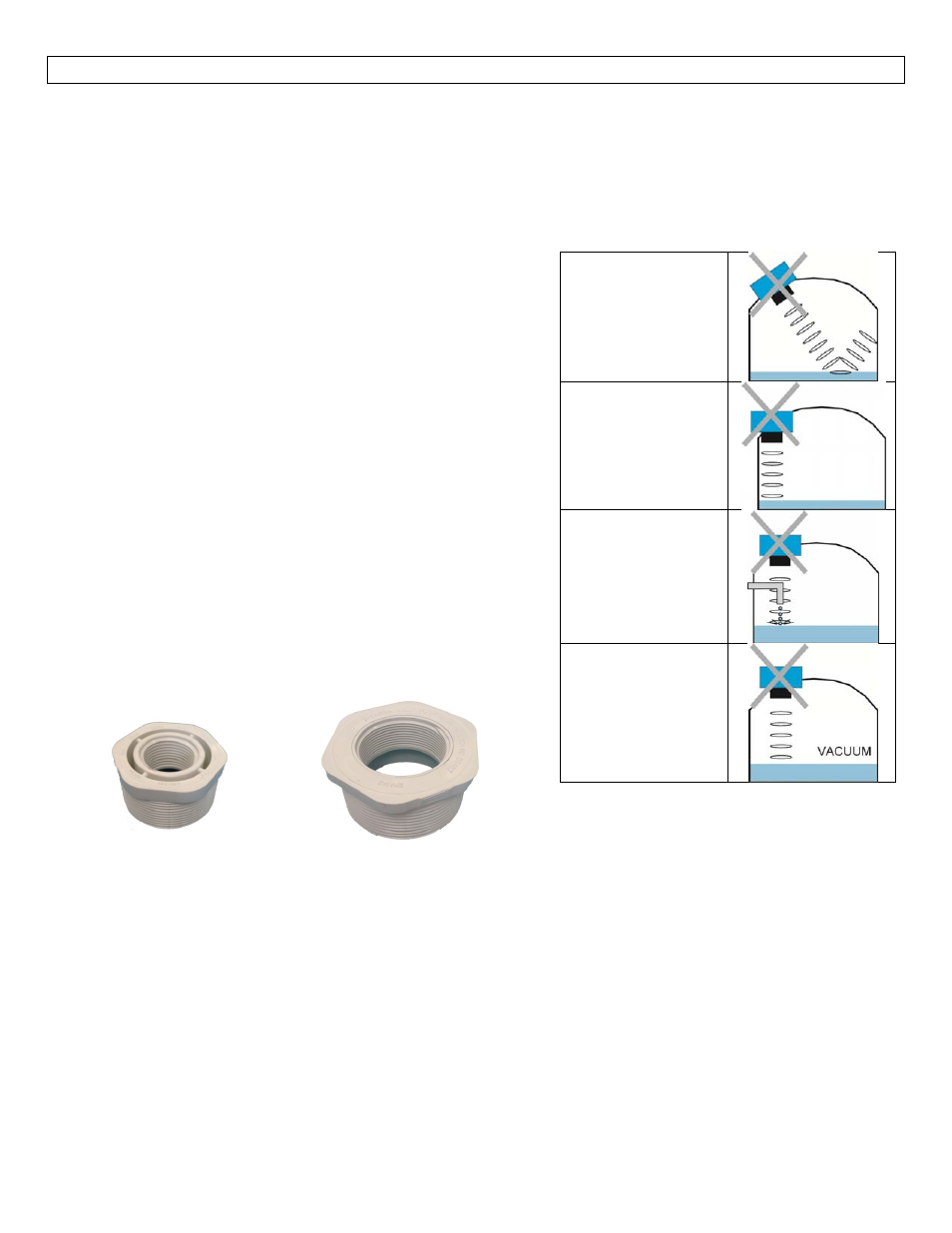

Mounting Guide

1. Do not mount at an angle.

2. Liquid should never enter the dead band.

3. Side Wall:

a. Mount at least 3” from the side wall.

b. For LU77 Series ‐ mount at least 2” from the side

wall.

4. Do not mount where obstacles will intrude into sensor’s

beam width.

a. Beam Width: 3” (7.6cm) diameter [2” (5cm) for

LU77 series].

5. Do not mount in a vacuum.

6. Avoid mounting in the center of a dome top tank.

7. In cone bottom tank, position the sensor over the

deepest part of the tank.

Installation in existing fittings: If the existing fitting is larger

than the threads of the EchoSwitch®, select a reducer

bushing such as the LM52‐1400 (2” thread x 1” thread) or

LM52‐2400 (3” thread x 2” thread).

LM52‐1400

LM52‐2400

Do not install at

angle relative to

the liquid.

Do not install

within 2” of tank

sidewall.

(3” for DL34 series)

Do not install with

objects in the

beam.

Do not install in

applications with

vacuum.

Metal Tanks (LU77 Series Only): Flowline ultrasonic sensors have been optimized for use in non‐metallic

fittings.

1. For best performance, avoid the use of metallic fittings.

a. Use a plastic 2” x 1” reducer bushing, such as the LM52‐1400 or a plastic 1” flange, such as the

LM52‐1850 for metallic tanks.

2. While installations directly into a 1” metal fitting are not recommended, acceptable results may be

obtained if the 1” fitting is a half coupling in form and the outer diameter of the coupling is tightly

wrapped in vinyl tape to dampen vibration.