Flowline LV55 FloaTek User Manual

Page 11

17 SEPT 08

Float-Tek LV55 Series

11 of 12

Rev A

MN201345

Maintenance

Maintenance should consist of inspection to see that the float is free to move and not coated with

any substance, which would change its weight or volume significantly. If this occurs, the float

should be cleaned. This is easily accomplished without disturbing the installation. In addition,

the stem may be wiped down to remove any build-up. The only repair possible in the field is

replacement of either the float or stem. Dents or nicks on the float are usually of no consequence

to operation.

Cautions

FLOWLINE manufactures a wide range of liquid level switches and technologies. While each

of these switches are designed to operate in a wide variety of applications, it is the user's

responsibility to select a switch model that is appropriate for the application, install it properly,

perform tests of the installed system, and maintain all components. The failure to do so could

result in property damage or serious injury.

1. The pressure, temperature and electrical limitations shown for the specified level sensor

must not be exceeded.

2. The pressures and temperatures must take into consideration possible surges in the

temperature and pressure of the system.

3. The liquids used must be compatible with the materials of construction. Specifications of

materials will be given upon request.

4. Life expectancy of the sensor varies with applications. Contact the factory if life cycle

testing is required.

5. Ambient temperature changes can affect sensor set points, since specific gravities of

liquids vary with temperature. Consult factory for assistance.

6. Level sensors have been designed to be shock and vibration resistant. For maximum life,

both should be minimized. Consult factory for assistance.

7. Excessive contaminants in fluid may inhibit float operation and occasional wipe down

may be necessary.

8. Physical damage to product may render product unserviceable.

9. Installation in a vessel made from magnetic materials may affect operation.

Testing the installation:

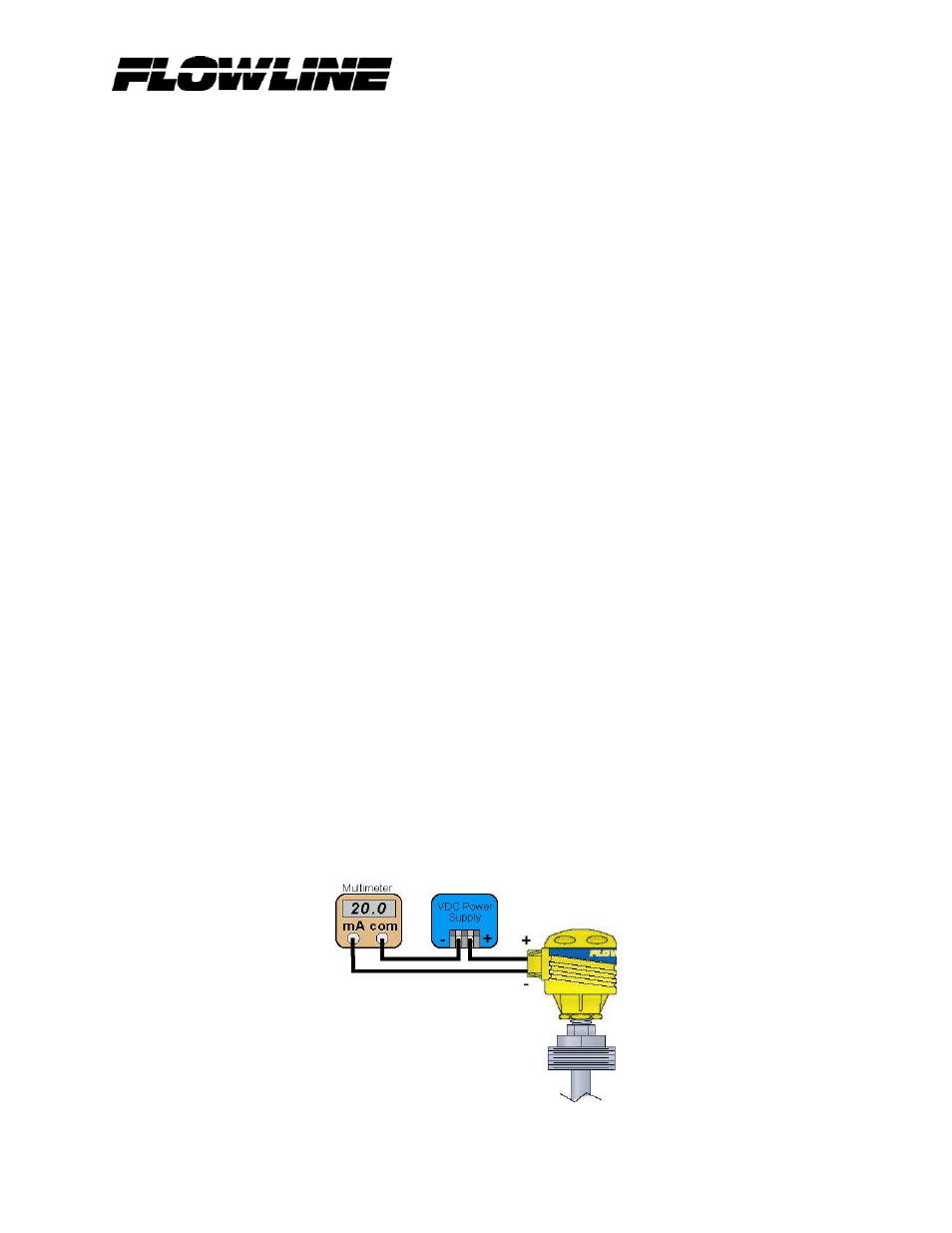

Verify proper wiring, power supply and loop resistance. If transmitter is not functioning

properly, isolate the transmitter from the system and wire as shown below. Multimeter should

read 4 mA with float at the bottom and 20 mA with float at the top of the transmitter.