Installation maintenance – Flowline LU30 EchoTouch User Manual

Page 6

Step Eight

Step Nine

INSTALLATION

MAINTENANCE

LOST Signal:

A reading of LOST in the display of the LU30 indicates the transmit-

ter is not receiving a valid return signal. If LOST appears, please

check the following troubleshooting items:

1. Beam cone interference such as the side wall, ladders, seams,

rungs or pipes within the LU30's beam cone.

2. Proper installation such that the LU30 is installed level and free

from interference from the installation fitting.

3. Sufficient power being supplied to the LU30. The LU30 requires

14-36 VDC power with a minimum supply of 200 mA.

4. Proper programming of the TANK function. For best results, set

the TANK function as the distance from the bottom of the tank to

the bottom of the transmitter.

5. Make sure that the transmitter is not installed at an angle. Even a

5 degree offset can reduce the signal return strength greatly.

Current is always 4mA or 20 mA:

If the output of the LU30 is always reading 4mA or 20 mA, check the

input values for the LU30. The display of the LU30 reads to the 1/10

of an inch or cm. A display of 1234 is 123.4" and not 1234".

Other Hints:

When checking the EC4 and EC20 values, the first value which

appears after EC4 or EC20 is the current distance from the bottom of

the transmitter to the surface of the liquid. Pressing either the [

s] or

[

t] buttons will then show the actual value in memory.

General:

The LU30 series sensor itself requires no periodic maintenance

except cleaning as required. It is the responsibility of the user to deter-

mine the appropriate maintenance schedule, based on the specific

characteristics of the application liquids.

Cleaning Procedure:

1.

Power:

Make Sure that all power to the sensor, controller and/or

power supply is completely disconnected.

2.

Sensor Removal:

In all through-wall installations, make sure

that the tank is drained well below the sensor prior to removal.

Carefully, remove the sensor from the installation.

3.

Cleaning the Sensor:

Use a soft bristle brush and mild deter-

gent, carefully wash the LU30 series sensor. Do not use harsh

abrasives such as steel wool or sandpaper, which might damage

the surface sensor. Do not use incompatible solvents which may

damage the LU30's Polypropylene or PVDF plastic body.

Internal Relay:

The LU30 series contains a 250 VAC, 10A, 1/2 Hp internal relay. The

relay is actuated by the HSET and LSET settings. While this manual

offers some examples and suggestions to help explain the operation of

the relay, such examples are for information only and are not intend-

ed as a complete guide to installing any specific system.

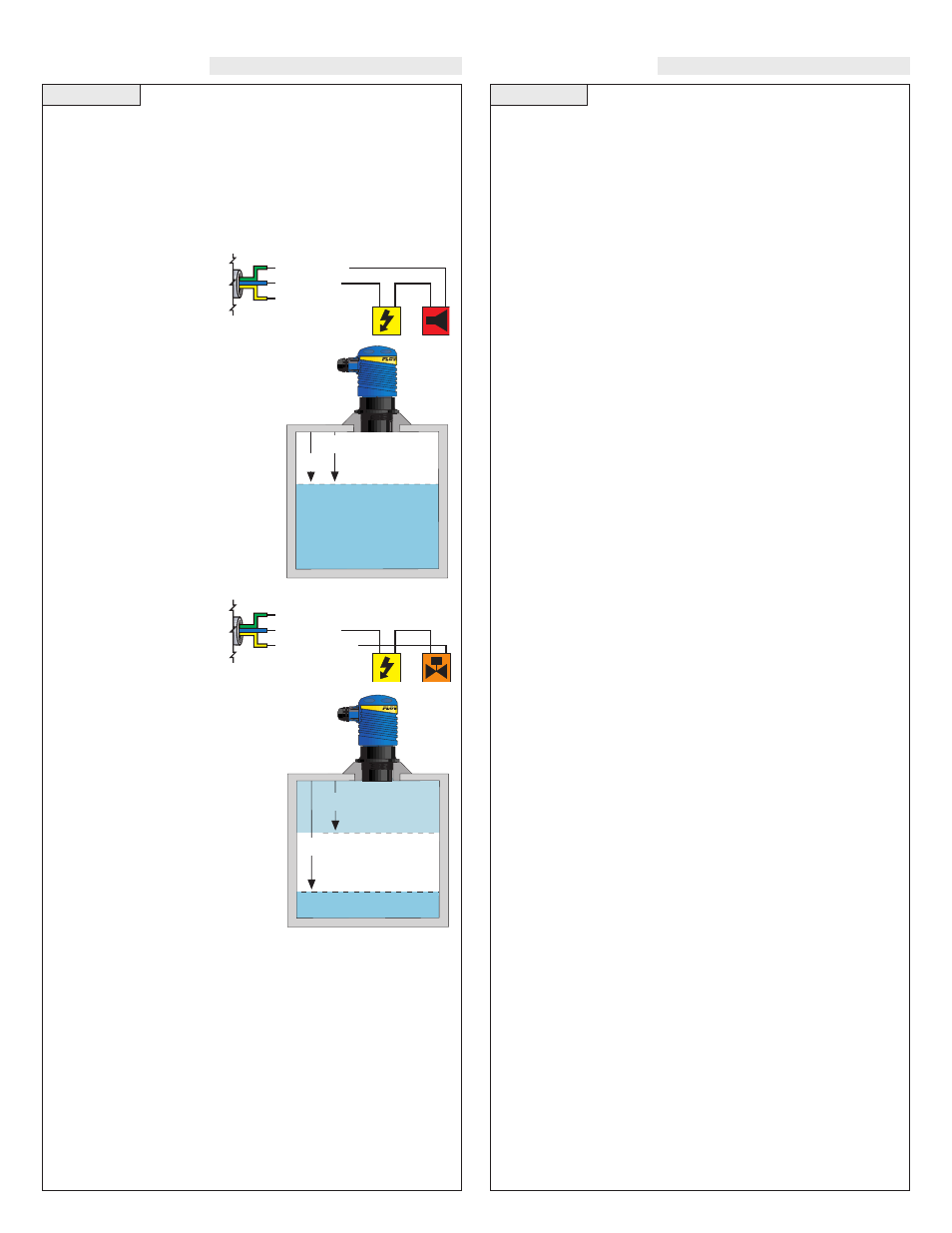

High Level Alarm:

The goal is to make sure the

liquid does not rise above a

certain point. If it does, an

alarm sounds alerting the operator to a high level

condition. Wire the hot lead of the alarm to the

Green NC relay wire. Also make sure the HSET

and LSET settings are programmed correctly.

Typically the values are set at the same distance

away from the LU30. In the normal operation

state, the LU30’s relay will remain

energized, keeping the alarm circuit

open. When the alarm level has been

reached, the relay de-energizes and

activates the alarm. To change to a low

level alarm, re-wire the alarm from the

Green NC wire to the Yellow NO wire.

Automatic Fill:

The goal is to fill the tank. A

valve is opened (energized)

when a low level is reached

and closed (de-energized)

when a high level is reached. Wire the hot lead

of the valve to the Yellow NO relay wire. Make

sure the HSET and LSET settings are pro-

grammed correctly. Typically the values are set

with the HSET as the valve close and the LSET

as the valve open. A pump or solenoid

can be substituted for the exact same

operation. When the low level is

reached, the system will start to fill the

tank. The tank will continue to fill until

the level reaches the high point. The

system stops filling until the low level

is reached again. To change to an auto-

matic empty application, re-wire the

system from the Yellow NO wire the

the Green NC wire.

- G r e e n

- B l u e

- Ye l l o w

NC

COM

NO

- G r e e n

- B l u e

- Ye l l o w

NC

COM

NO

HSET

LSET

De-Energized

Relay

Energized Relay

HSET

LSET

De-Energized

Relay

Energized Relay