Assembly instructions – Allstar Products Group CHALLENGER AC9300 User Manual

Page 5

5

NOTE:

The Rail/Chain Assembly is

packaged separately from the Power

Head Unit. The trolley, front idler/

tension adjustment assembly, chain,

drive gear and limit cams are assembled

to the Rail/Chain Assembly at the

factory. Follow the steps outlined

below to complete assembly prior to

installation. Refer to the component

identification illustrations on the

previous page.

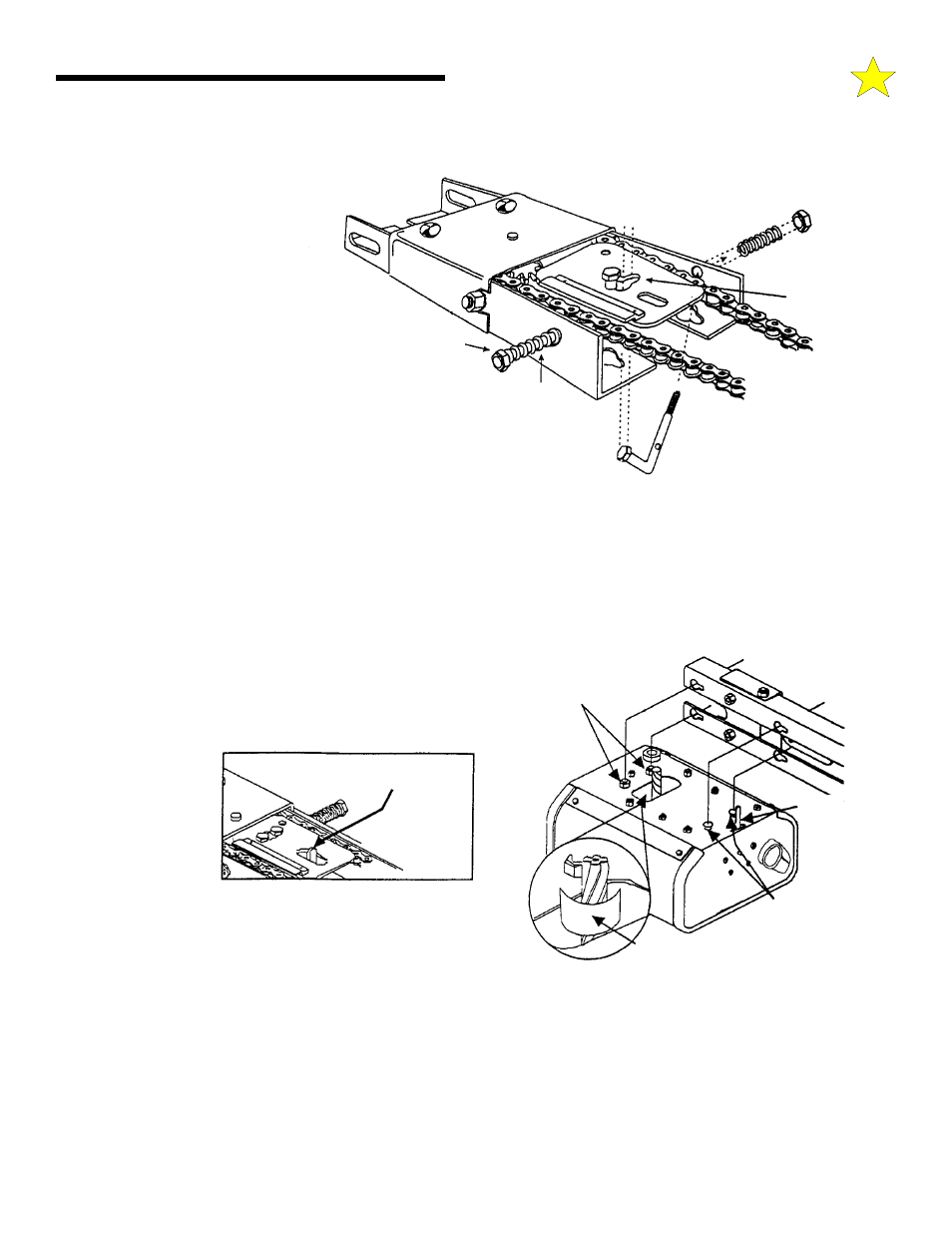

STEP 1:

Prior to attaching the motor

drive unit to the rail assembly, the Open

and Close adjustment bolts must be

installed. Place the threaded end of the

adjustment bolt through the hole in the

rail and then slip the head of the bolt

through the center of the double key

hole. Slide the spring over the bolt and attach load adjusting nut. Tighten until the tip of the bolt extends 3/16” outside the nut.

Repeat above for the other side.

STEP 2:

Protect the Power Unit cover from scratching during assembly by placing it on cardboard. Loosen the two 5/16" lock

washer nuts on top of the power head drive unit.

STEP 3:

VERY IMPORTANT !

Position a paper shim around the power head unit drive gear (standard weight paper, see

illustration). Shim must remain in place while assembling the power head unit to the Rail/Chain assembly to ensure a proper gear

mesh and avoid excessive long term wear.

STEP 4:

Align the four key holes in the Rail/Chain assembly with

the two front guide tabs and the two rear bolt studs on the power

head unit and place the rail/chain assembly in place over the power

head unit. The power head drive unit limit lever protrudes up

through the rail/chain assembly sensing plate. Take care not to bend

t h e l e v e r w h e n

assembling. Slide the

power head drive unit

forward until the gear

meshes with the rail/

chain assembly drive

gear. Check to make

sure the front guide tabs

on the power head unit

are securely locked on

the rail/chain assembly.

STEP 5:

The power head drive unit should be move forward until

all play between the gears has been eliminated, but no additional force should be used that could cause pressure on the motor (power

head unit) drive gear. Tighten the two 5/16" lock washer nuts on top of the power head drive unit that were loosened in Step 2 above.

When the opener is first activated the paper shim will be ejected. The paper shim should have the profile of the gears to indicate the

proper mesh between them.

STEP 6:

Recheck the nuts used to secure the Rail/Chain assembly to the Power Head Unit, making sure they are tight.

Assembly is now complete and you are ready to begin installation of the opener.

If Your Opener Is Supplied Fully Assembled, Please Disregard This Page.

A:

ASSEMBLY INSTRUCTIONS

Assembled and

In Position

Spring

Spring

Force Adjusting

Plastic-Insert

Locking Nut

L-Shaped Adjustment Bolt

Double Key Hole

Limit Lever

Take care not to

bend limit lever

5/16” Lock

Washer Nuts

110047-1

110047-3

110047-2

Limit

Lever

Front Guide

Tabs (2)

Paper Shim