Climacool – ClimaCool FLEX SERIES 30, 50, 65 User Manual

Page 26

24

ClimaCool

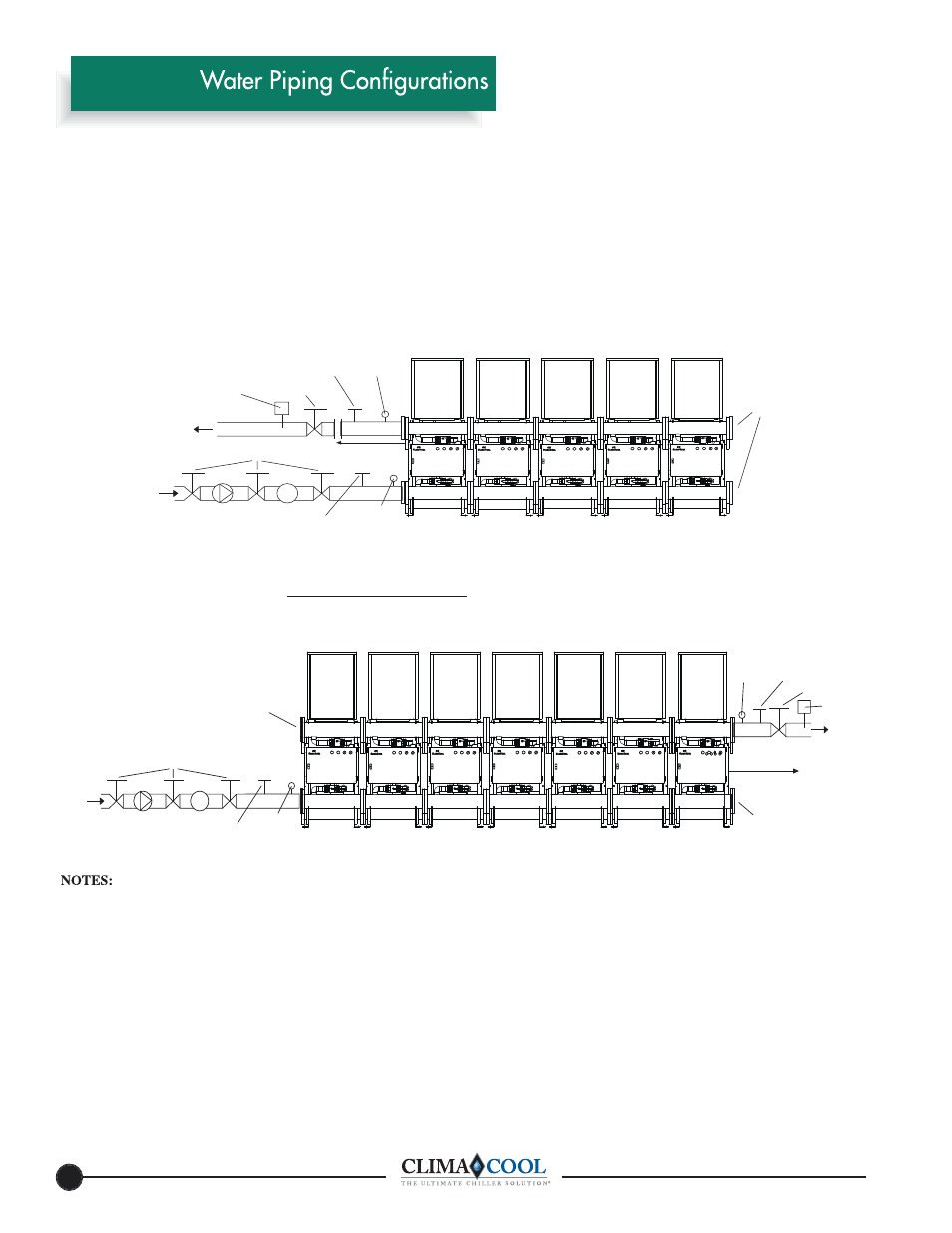

Field Piping Direct Return - 1 to 5 Modules (Figure 1)

Unit 1

Unit 2

Unit 3

Unit 5

Unit 4

Blank Off

Plates

60” Sensor Location

(Field-Installed)

PressureTaps

with Shutoff Valves

& Gauges

Flow Out

Flow Switch

Isolation Valve

Thermometer Well

Thermometer Well

PressureTap

w/Shutoff

Valve &

Gauge

Isolation Valves

Strainer

Pump

Flow In

Blank Off

Plate

Blank Off

Plate

60” Sensor Location

(Field-Installed)

7

t

i

n

U

3

t

i

n

U

2

t

i

n

U

1

t

i

n

U

Unit 6

Unit 5

Unit 4

Thermometer Well

PressureTap

w/Shutoff

Valve &

Gauge

Isolation Valves

Strainer

Pump

Flow In

Flow Out

Thermometer Well

Flow Switch

Isolation Valves

Pressure Taps

with Shutoff Valves

& Gauges

1. Figures 1 and 2 are required piping for proper water regulation and distribution through ClimaCool

®

modular chillers.

2. Module order and incoming/outgoing water fl ow as shown in both Figure 1 and 2 can be set up as either a left-to-right or

right-to-left confi guration.

3. Condenser Hydronic Circuit shown. Piping confi gurations are similar for the chilled water hydronic circuit.

4. For condenser and chilled water (evaporator) inlet/outlet location dimensions, refer to page 20 - Module Dimensional Data.

5. A differential pressure fl ow switch is a required safety device for ClimaCool

®

modular chillers on the chilled and condenser

water circuits.

6. Maximum water fl ow rates for both evaporator and condenser water header systems in one bank of modules is 1000 GPM.

Field Piping Reverse Return - (Preferred 1 to 5 modules) Required for 6 to 7 Modules (Figure 2)

www.climacoolcorp.com

®