Water supply requirements, Maintenance information – Schreiber Chillers Hypertherm Part No 039104 User Manual

Page 24

24

Water Supply Requirements

Schreiber Water Chiller

The water chilling system is designed to operate in conjunction with a Hypertherm

Plasma Cutting System. The chiller has the same water supply requirements as the

plasma system. Maintaining the water purity level to meet the specifications of the

plasma system is compatible with the operation of the chiller. Shown below is the Water

Purity Specifications as found on page 3-3 of the Hypertherm Manual.

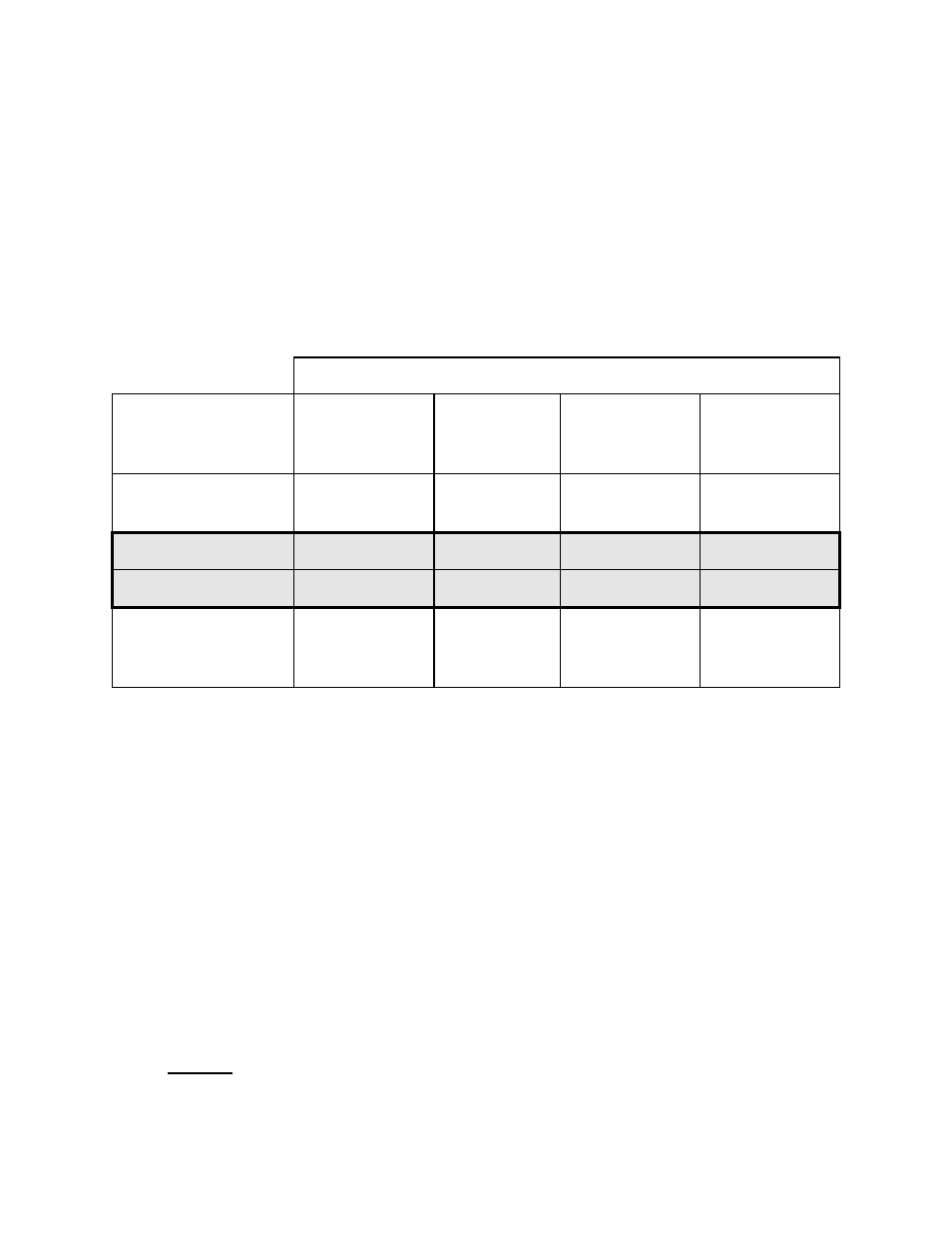

Water Purity Measurement Methods

Water Purity

Conductivity

µS/cm

at 25

o

C

Resistively

mΩ~cm

at 25

o

C

Dissolved

Solids

(ppm of NaCl)

Grains per

Gallon

(gpg CACO

3

)

Pure Water

(ref.only)

0.055

18.3

0

0

Maximum Purity

0.5

2

0.206

0.010

Minimum Purity

18

0.054

8.5

0.43

Max Portable

Water

(Reference only)

1000

0.001

495

25

MAINTENANCE INFORMATION

1. There are no lubrication points on the chiller. All motors have permanent

lubrication in the bearings.

2.

The water that is used in the chilled water circuit has the same specification as

required by the plasma system. The water should be clean and some type of

water conditioner can be used. Nothing should be used in the chilled water circuit

that could damage the all copper Heat Exchanger.

3.

The air cooled condenser should be cleaned on a regular basis, depending on

the environment the chiller is installed in.

4.

The water level should be maintained as close to the level as marked on the

water sight glass. You cannot damage the refrigeration system by the water

being at a low level, it will only effect the efficiency of the unit.

5.

Caution: The compressor receivers and water pump could be hot enough to

injure one touching these components.

6.

The dial thermometer is reading the temperature of the discharge chilled water.