PA Industries Transporter User Manual

Page 4

4

INSTALLATION

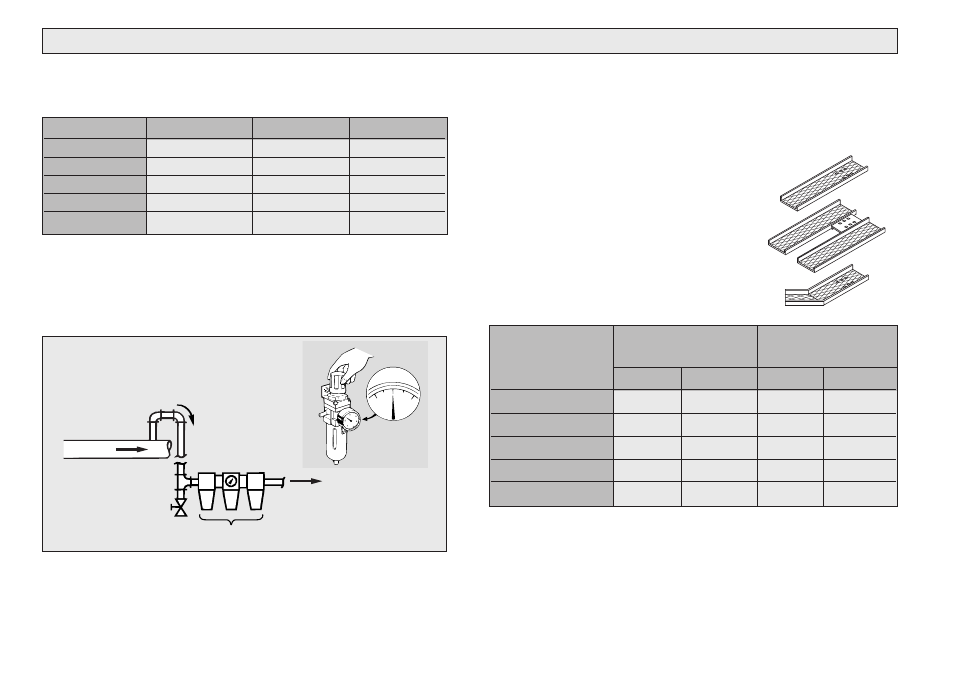

4. Connect the Air Line with flexible poly-flow tubing into

the threaded inlet. On Model TP-3 use 1/4” tubing for

1/8” NPT. Models TP-10, TP-40, TP-70 and TP-140 use

3/8” tubing for 1/4” NPT.

5. A custom “U” profile tray or chute

must be designed to handle each

specific application or tool. Any

material can be used, but we

recommend aluminum or any light

gauge material to reduce tray weight.

Maximum tray weight should not

exceed the following table data:

3. Fill the Lubricator with a good grade of hydraulic oil

such as Shell Tellus 32 or equivalent. Set the Lubricator

for one (1) drop per minute.

2. Air line requires use of an oil mist-type combination

Filter/Regulator/Lubricator, and Pressure Gauge. Set

pressure to 4-5 Bar (60 to 75 psi). Do not exceed 5.5 Bar

(80 psi) as excess pressure will damage the Transporter.

1.

Rigidly Mount the Transporter to a solid surface using

these recommended bolts sizes:

Model

Quantity

Metric

Inch

TP-3

4

M 8

5/16

TP-10

4

M 8

5/16

TP-40

2

M10

3/8

TP-70

6

M 8

5/16

TP-140

6

M 8

5/16

60

(4)

75

(5)

Max. Weight Max. Weight

Tray Only

of Parts

Tray & Scrap

Model

Kg

Lbs.

Kg

Lbs.

TP-3

1,5

3.3

3

6.6

TP-10

3

6.6

10

20

TP-40

15

33

40

80

TP-70

50

110

70

140

TP-140

100

200

140

300

Recommended Air Line

Connection to Eliminate Moisture

and Particles from Main Line

Filter/Regulator/Lubricator

To Transporter

Drain

Main Air Line

6. Fasten the tray or chute to the Transporter with metric

screws at all holes. Be sure to use spacers or washers

between the Transporter and the tray to reduce contact

friction between the moving tray and the Transporter

body. Refer to the following table.