Generic pid controller calibration – MoTeC DBW-4 User Manual

Page 11

MoTeC DBW-4

11

Introduction

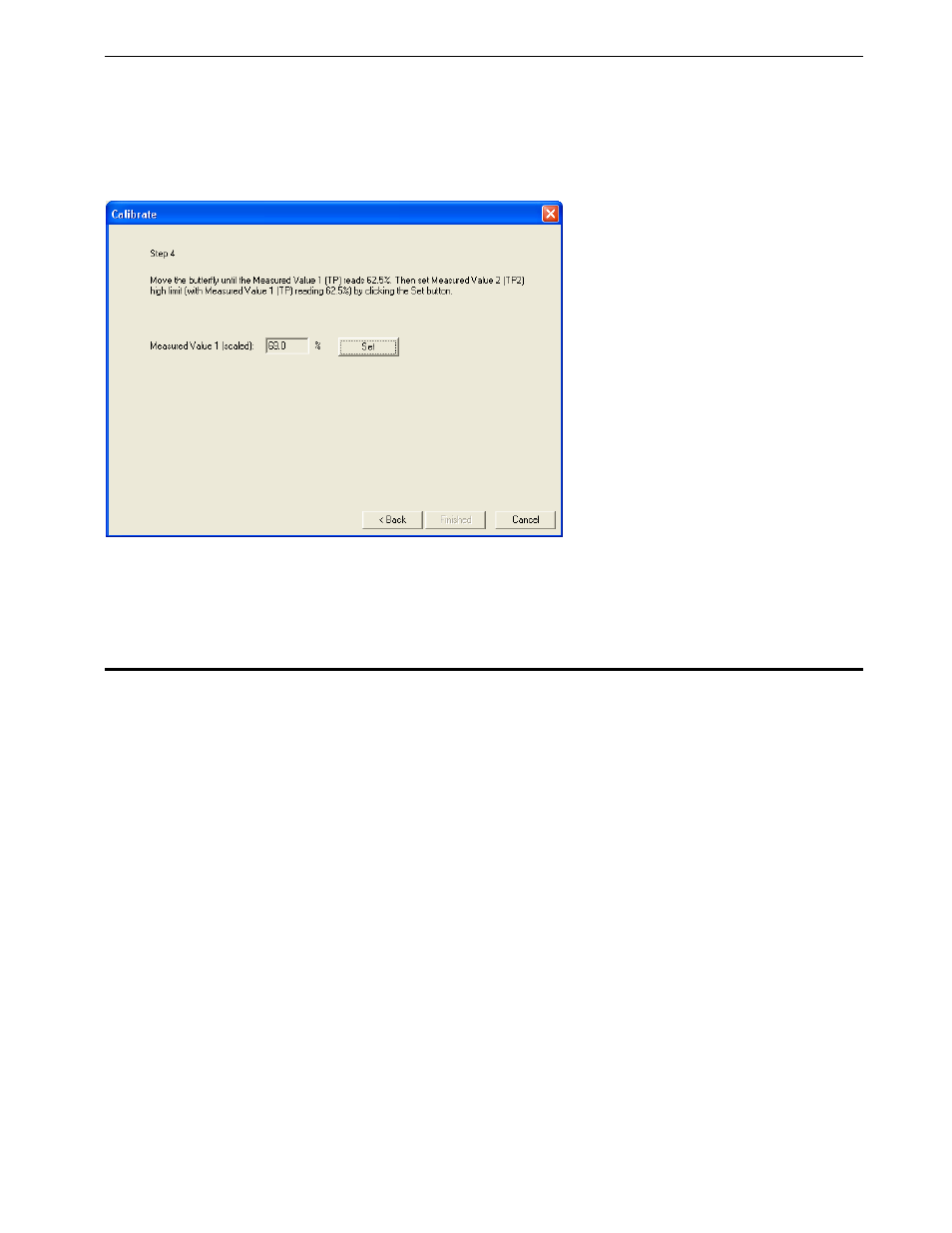

This step is only applicable for DBW throttle bodies with a “knee” characteristic for the Meas2 (TP2) sensor (eg.

Meas2 Max % Target = 62.5%), where the high limit is measured separately for measure value 1 (TP) and measured

value 2 (TP2).

Set the high limit for the measured value 2 (TP2) by following the instructions displayed (see below). It is important to

position the butterfly as close to the target (eg. 62.5%) as possible when setting measured value 2. Note that the Set

button can be pressed again if the butterfly position was set incorrectly. When the measured value 2 high limit

position has been set, click Finished to continue.

Step 8:

When all calibrations have been performed, send the configuration to the DBW-4 by pressing the F5 key.

Generic PID Controller Calibration

To calibrate a generic PID controller, the high and low limit positions must be measured and included in the

calibration. The procedure calibration procedure described here should be repeated for each PID controller

connected to the DBW-4.

Step 1:

Run the DBW-4 software and load the appropriate configuration file for the connected device, or enter the

appropriate PID parameters.

Step 2:

Connect the CAN cable from the PC to the DBW-4 and apply power to the DBW-4. Ensure that only the sensor

wiring (TP, +5V and 0V) is connected to the device and that the wiring to the actuator is disconnected before applying

power.

Step 3:

Click on the Tab (PID1 to PID4) for the controller to be calibrated. Ensure that the Group type for the controller is set

to “Other”. Press the Calibrate button to begin the calibration. After reading the displayed safety warning and

checking the actuator wiring, click Next to continue.

Step 4:

Set the low limit for the measured position by following the instructions displayed (see below). For indication

purposes, the raw position value will be displayed as the actuator position is changed. Note that the Set button can

be pressed again if the measured position was set incorrectly. When the low limit position has been set, click Next to

continue.