Assembly prior to reassembly – DE-STA-CO 662P User Manual

Page 6

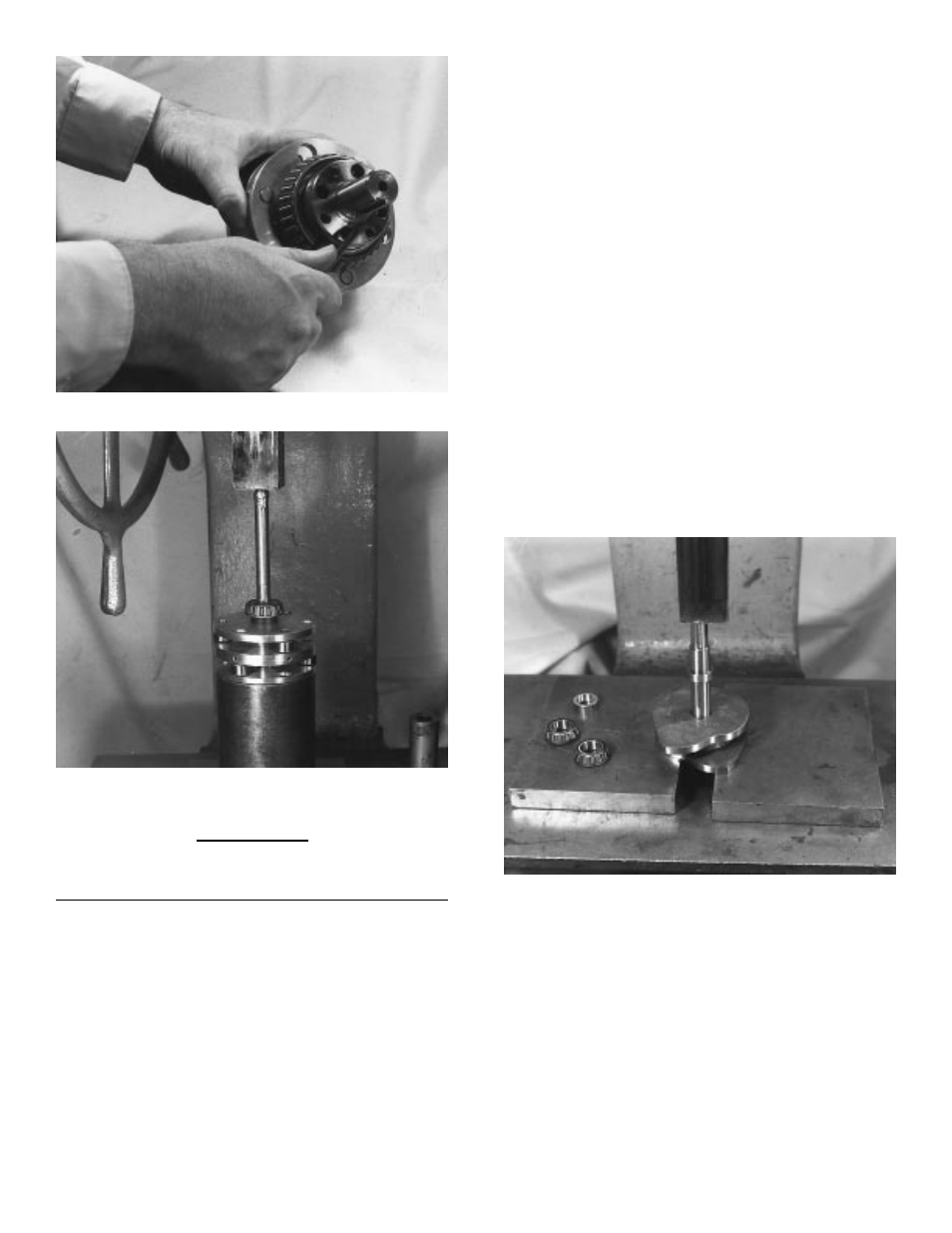

Fig.6 Removing follower wheel fasteners.

B. Use arbor to press follower wheel onto

shaft. Be sure the fastener and dowel holes

line up. Coat shaft and bore with anti-seize

lubrication proir to pressing. If a heat gun is

available it is recommended the bore of the

follower wheel be heated prior to pressing.

C. Tighten socket head capscrews.

D. Reinstall output shaft spacers removed

during disassembly.

E. Use arbor to press bearing cones onto

shaft. Coat shaft and bearing bore with anti-

seize lubricant prior to pressing. If a heat

gun is available it is recommended the bore

of the bearing be heated prior to pressing.

2. INSTALLING CAMS

A. Use arbor to press cams onto shaft. Be sure

the fastener and dowel holes or key and

keyway line up. Apply anti-seize lubricant to

the cam bore and shaft prior to pressing. If a

heat gun is available it is recommended the

bore of the cams be heated prior to

pressing.

Fig.7.1 Pressing out shaft.

ASSEMBLY

PRIOR TO REASSEMBLY

Clean and deburr all parts before reassembly.

Follow tightening torque and Loc-tite

™

recommendations as outlined in the General

Service Manual.

1. INSTALLING FOLLOWER WHEEL

A. Install dowels in the back side of the flange

portion of the output shaft (to match up with

the precision holes in the follower wheel

during assembly).

Fig.7.2 Pressing in shaft (250P)

B. Loosely tighten cam mounting screws but

do not drive in dowel pins. This note does

not apply to the 250P OR 387P since they

are one piece cams fastened to the shaft

with keys.

C. Reinstall input shaft spacers removed

during disassembly.

D. Use arbor to press bearing cones onto

shaft. Coat shaft and bearing bore with anti-

seize lubricant proir to pressing. If a heat

gun is available it is recommended the bore

of the bearing be heated prior to pressing.

5