Index drive oil capacities (approximate), Oil seal installation recommendations – DE-STA-CO INDEX DRIVES GENERAL SERVICE MANUAL User Manual

Page 7

6

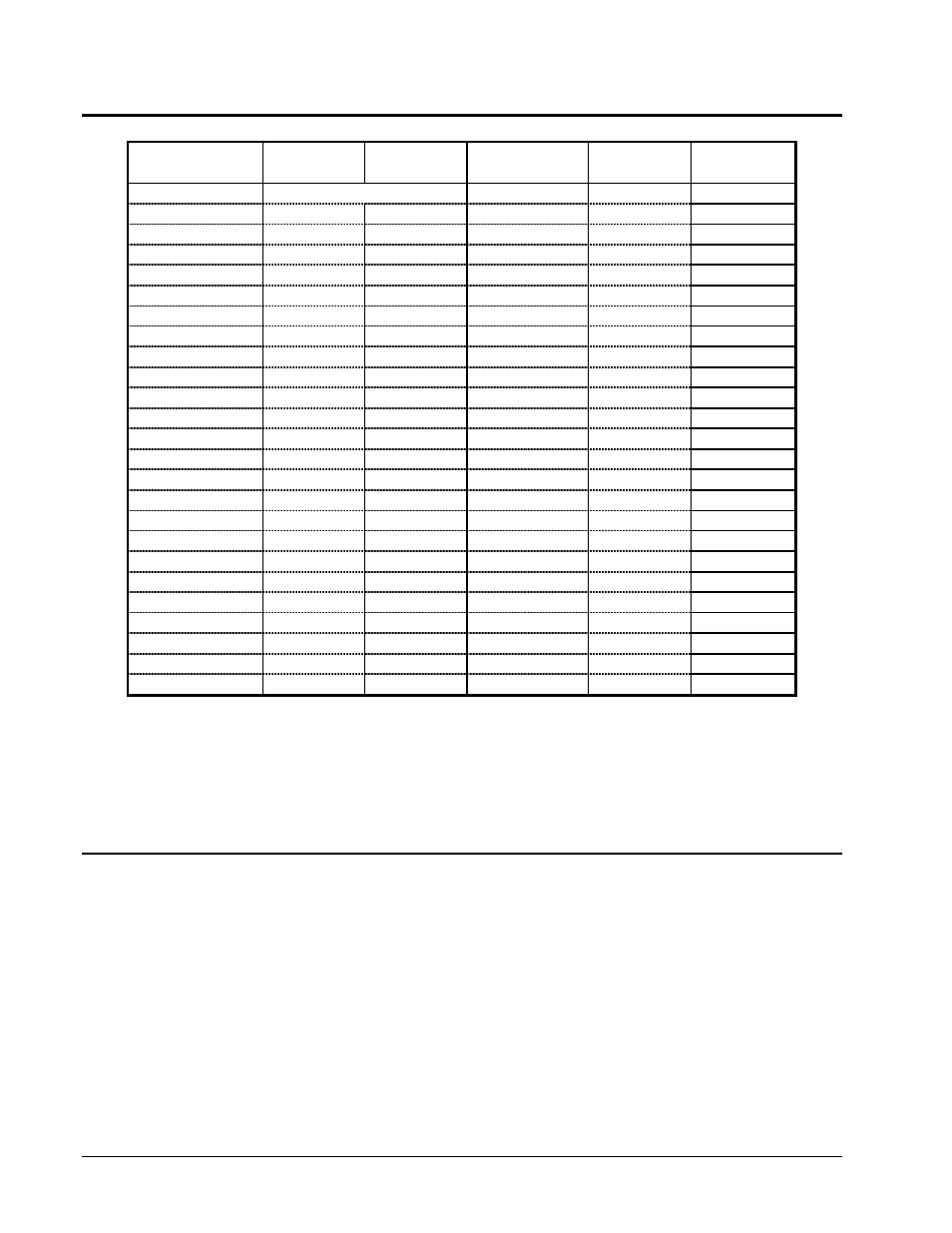

Index Drive Oil Capacities (Approximate)

For indexers mounted in the normal* position. Consult IMC for units not listed.

Model No.

US.

Metric

Model No.

U.S.

Metric

(quarts)

(liters)

(quarts)

(liters)

80RDM

Grease filled**

40RGD/S

6 oz.

0.2

601RDM

2

2

50RGD/S

16 oz.

0.5

902RDM

3

3

70RGD/S

20-24 oz.

0.6-0.7

1100RDM

8

8

80RGD/S

30-38 oz.

1-1.1

1305RDM

9

9

110RGD/S

C/F

C/F

1800RDM

36

34

350RGD/S

1

1.4

425RD

2

2

500RGD/S

5

4.7

800RD

5

5

700RGD/S

10

9.5

1301RD

14

13

1801RD

36

34

1100RNG

C/F

C/F

1550RNG

C/F

C/F

250P

1

1

2050RNG

C/F

C/F

387P

2

2

512P

5

5

750E

C/F

C/F

662P

10

10

950E

10 gallons

38

900P

20

19

1150E

25 gallons

95

1200P

48

45

1550E

40 gallons

152

1800P

95

90

2050E

45 gallons

171

2750E

75 gallons

285

401RA (C)

1

1

512RA(CC)

2

2

150RPP

2.5

2.4

662RA(CCM)

6

6

300RPP

4

4

663RAD(DR)

4

4

500RPP

10

9

900RAD(GH)

6

6

900RPP

48

45

* Normal indexer mounting position is output vertical over input on all models except the "Parallel series" (P)

in which normal mounting is output horizontal, even with input. “Output Vertical” refers to the direction of the

center of rotation. For dial-type indexers, this is the position with the dial horizontal.

** “Grease-filled” units are shipped with grease. Grease should only need to be added if the unit is

disassembled for rebuild or repair.

C/F: Consult IMC for information

Oil Seal Installation Recommendations

IMC recommends that all seals be replaced any time the device is being disassembled regardless

of whether they are damaged or not. Most damage to oil seals occurs at assembly when

recommended seal installation procedures are not followed.

1. Check dimensions -- to be sure that shaft and bore diameters match those specified for the seal

selected.

2. Check seal -- for damage that may have occurred prior to installation. A sealing lip that is turned

back, cut or otherwise damaged should be replaced.

3. Check bore -- to see that the leading edge is deburred. A rounded corner of chamfer should be

provided.