American Expedition Vehicles Tummy Tucker – TJ Rubicon models User Manual

Page 5

Installation Instructions:

Tummy Tucker™ – TJ Rubicon models

Nth30116 v4.doc

page 5 of 13

www.aev-conversions.com

Fig. 6

Fig. 7

Step 6e: Rearrange Wiring. As you may have already done at this point, some of the wires leading to

and from the four connectors that were mounted to the locker pump bracket can be unplugged and

rerouted around each other to better suit the new location. Once this is done, the wires will need to be

zip-tied to the frame-mounted fuel/brake lines.

Step 6f: Reroute Hoses. There are some simple modifications to allow the hoses to reconnect:

-

remove the large (about 1”) diameter plastic ‘convolute’ sheathing that holds the rear locker pump

hose and wires along with the larger air intake hose coming from the fuel filler area. By zip-tying the

intake hose to the fuel and brake lines along the driver’s frame rail, you can ‘save’ a large amount of

this intake hose length – it will be more than enough to reattach it to the plastic ‘T’ at the back of the

locker pump bracket. You may need to gently pull a little extra length from above the fuel tank as

well. There will be enough to allow you to cut off about 3” of extra hose.

-

Use the 3” of intake hose plus the supplied ¼” barbed union fitting to reconnect the front locker pump

to the plastic ‘T’ (The ‘T’ should be at the very back of the bracket, with the rear locker hose straight

out instead of bent 90 degrees as it was originally). Secure the remaining small hose and wires that

go to the rear axle along the left-rear upper control arm or as appropriate to allow full suspension

motion, etc.

-

Next, cut 7.5” off of the small diameter

hose going to the front axle and reattach it

to the front locker pump – you will need to

remove the last tape wrap and turn the

hose around 180 degrees to fit onto the

pump.

-

Use the 7.5” piece of small tubing and the

supplied 3/16” barbed union fitting to

extend the rear locker’s small hose. This

should make the rear hose long enough to

reattach to the rear locker pump.

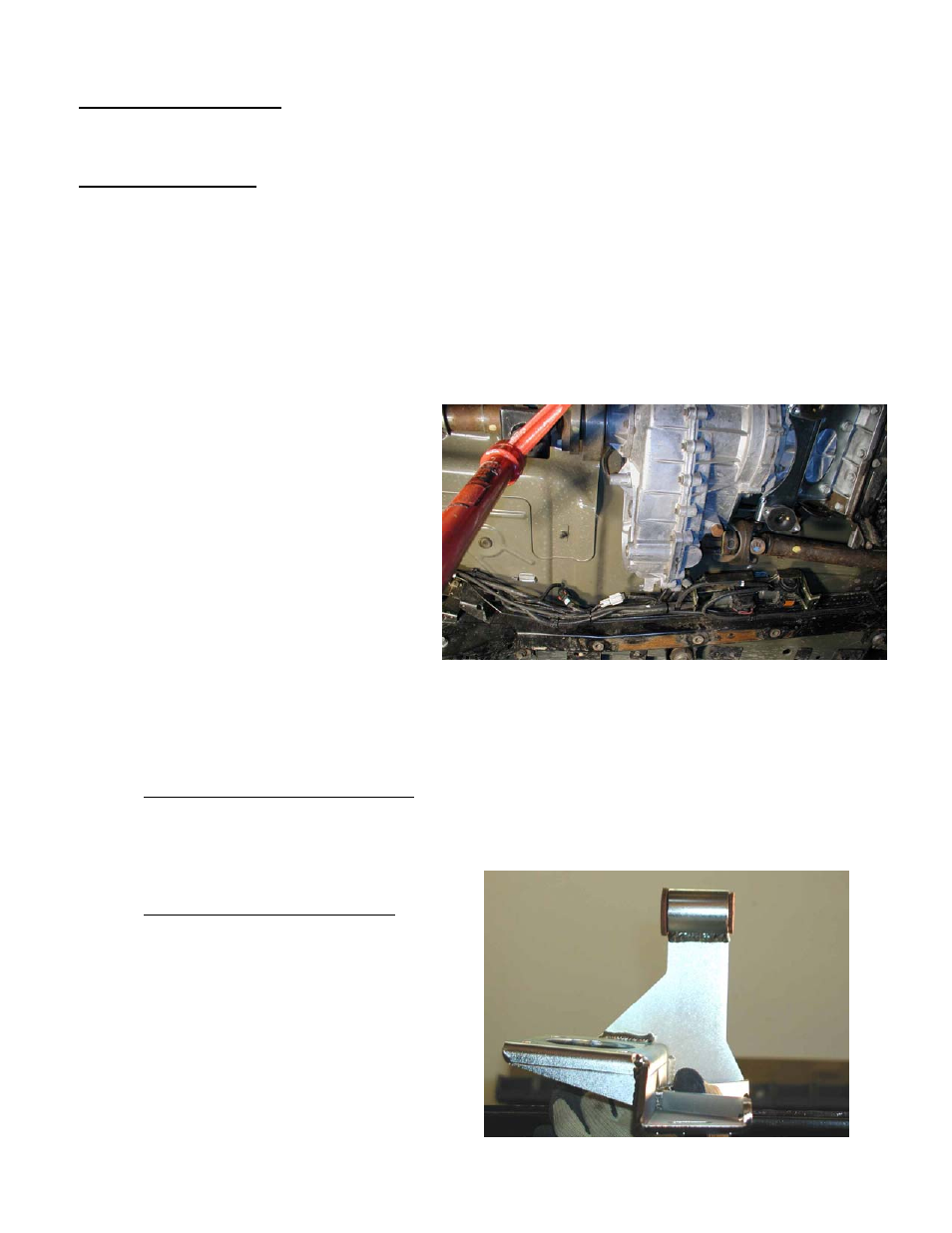

Figure 6 shows how everything should be

hooked up again, with nothing stretched too

tight or hanging where it could be damaged. Ideal routing of the various harnesses should be apparent

and can be held in place with a few added zip-ties. It is especially recommended to make sure that none

of the hoses/lines are hanging free and close to where they could get tangled in the front drive shaft – if

you keep everything ‘inside’ the locker bracket’s flanges, you will not have any problems. Final

attachment to bracket to the TT will occur in step 12 after the TT is bolted in.

Step 7: Remove Stock Transmission Mount. Remove the four bolts that attach the bracket to the rear-

underside of the transmission (5/8” heads) – there is no need to remove the isolator itself from the

adapter bracket. Once the bracket is loose, slide it rearward until the exhaust steady rest isolator slips

off of the hanger pin (solid rod that is welded to the pipe ahead of the catalytic converter.) These parts

will not be reused with the TT.

Step 8: Remove exhaust hanger bushing. You will

re-use the exhaust steady rest isolator bushing

from the original bracket. To remove it, note that

the rear (as it was installed on the Jeep) end of the

isolator has a smaller lip on it than the front – push

the isolator out from this end towards the front

using a ¾” socket (using a larger socket will shear

off the small lip). Replace the isolator in the same

orientation in the tube on the new bracket – it will

be much easier if white-lithium grease is sprayed

inside the tube. See figure 7 for completed

conversion orientation.