Elmo Rietschle L-BV5 Supplementary instructions User Manual

Page 6

Concerning 5 Installation

610.44440.40.200

6 / 12

© Gardner Denver Deutschland GmbH

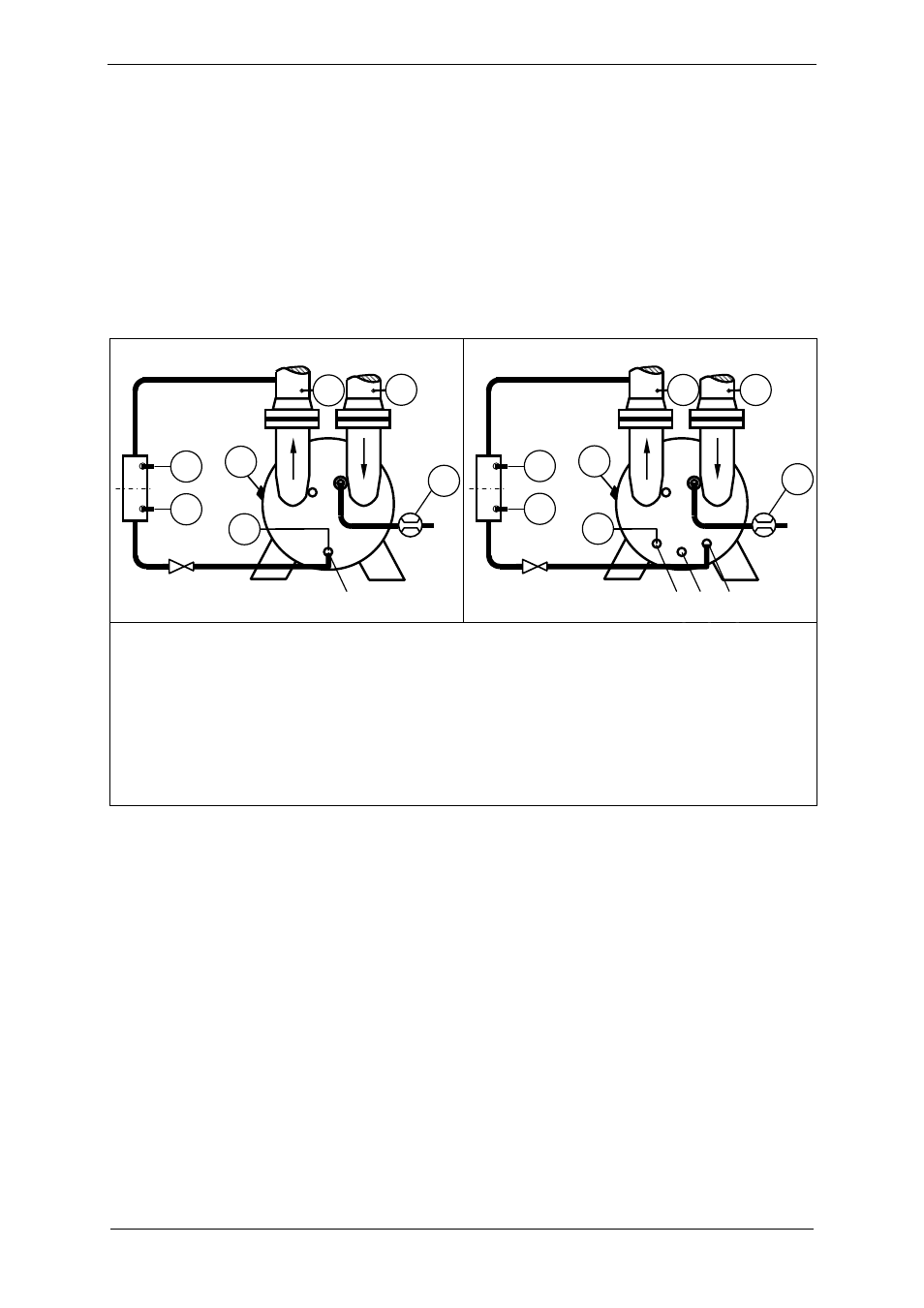

b) Operating fluid temperature measurement in

the drain tapping (F2, Fig. 1, page 6), or on

the unit housing (F5, Fig. 1, page 6) with

suitable temperature sensor.

Disconnection condition:

Temperature ≥ 60 °C (140 °F)

The measurement and control device must be

suitable or certified to take reliable

measurements for disconnection conditions and

shut down the equipment if necessary.

The device must be certified with regard to its

point of installation in accordance with its

category.

It is recommendable to implement the monitoring

systems in accordance with EN ISO 13849.

The volume flow measurement sensor must be

suitable for the area prevailing in the measuring

point internal space.

2BV2 0..

2BV5 1..

F1 Flow measurement in the operating fluid feed.

G1 Pressure measurement in propellant gas on

suction side, to monitor suction pressure

p

1

≤ p

vapour

+ 50 mbar

F2 Temperature measurement in the operating

fluid.

G2 Pressure measurement in propellant gas on

suction side as overload protection.

F3 Liquid level for operating liquid, maximum.

A Drain tapping

F4 Liquid level for operating liquid, minimum.

B,C Drain tapping (only 2BV5 1..)

F5 Temperature measurement on housing

Fig. 1: Position of measuring points

Monitoring liquid level before starting up

Monitoring the liquid level before starting up is

compulsory.

Monitoring can be ensured, for instance, by

inductive proximity switches, solenoid-operated

sensors, or pressure-dependent sensors, each

combined with an analysis device.

The liquid level switches (F3, F4, Fig. 1, page 6)

should be installed in the liquid level monitoring

device (position Fig. 1 page 6).

The monitoring device sensors must be non-

corrosive and certified for category 2 if there is

direct contact with the internal space.

The measurement and control device must be

suitable or certified to take reliable

measurements for disconnection conditions and

shut down the equipment if necessary.

The device must be certified with regard to its

point of installation in accordance with its

category.

It is recommendable to implement the monitoring

systems in accordance with EN ISO 13849.

The liquid level monitoring sensor must be

suitable for the area prevailing in the measuring

point internal space.

It must only be possible to turn on the unit if the

given fluid level stands between h

f min

and h

f max

(Fig. 2, page 7).

F2

F3

F4

F1

G1

G2

F5

B

C

A

F2

F3

F4

G1

F5

G2

F1

A