Concerning 3 technical data, Concerning 5 installation – Elmo Rietschle L-BV5 Supplementary instructions User Manual

Page 5

Concerning 3 Technical Data

© Gardner Denver Deutschland GmbH

5 / 12

610.44440.40.200

Concerning 3 Technical Data

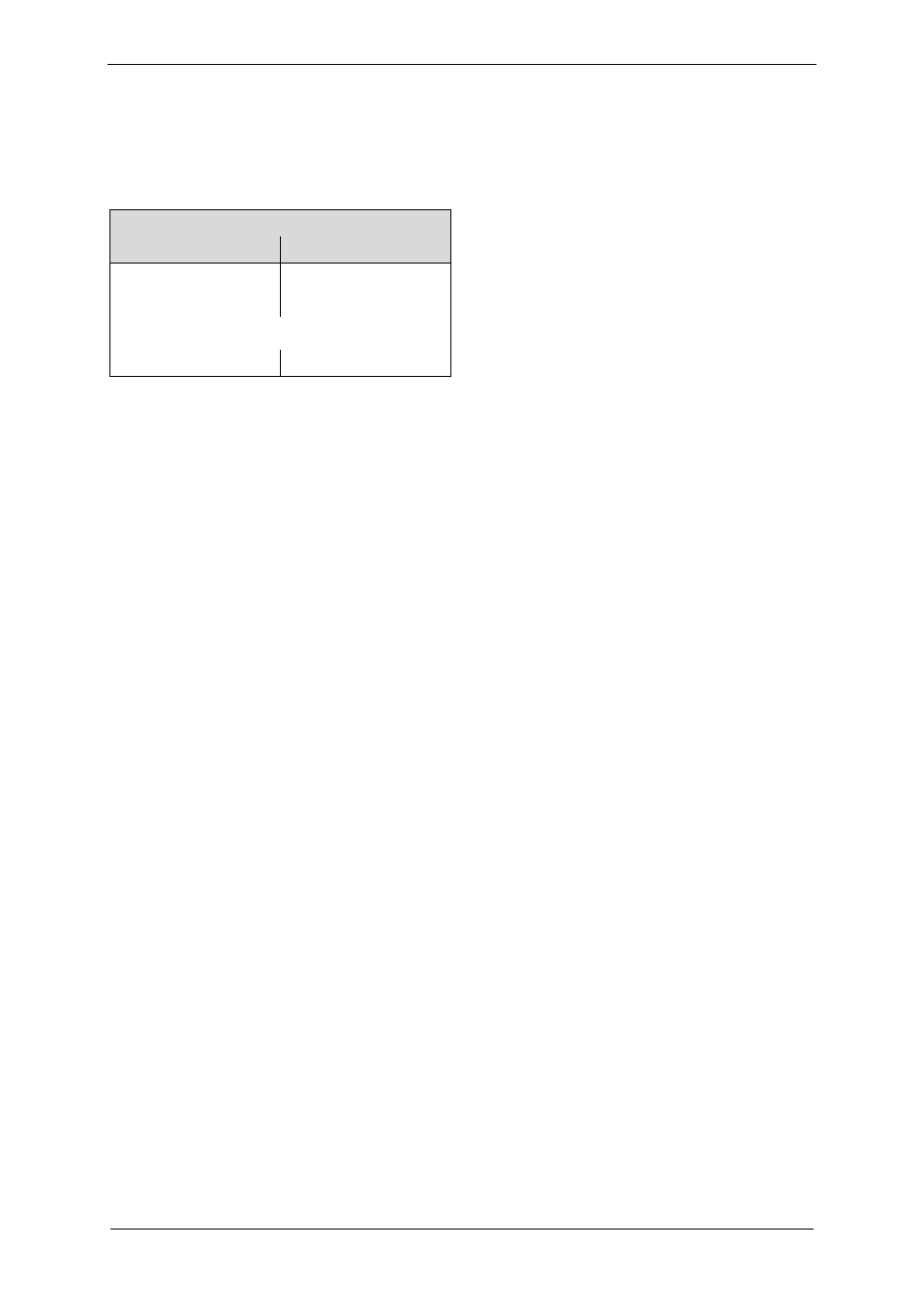

Concerning 3.3 Operating conditions,

normal operation

...............

Temperatures

Temperature of the operating liquid

[°C]

[°F]

max. +65

max. +149

min. +5

min. +41

Nominal value:

+15 +59

Pressures

Minimum suction pressure of the gas

If an explosive gas mixture should arise due to

ambient air entering the unit, the use of process

gas must be ensured for the cavitation protection.

If the unit suction pressure (p

1 min

) doesn’t stand

at a minimum of 50 mbar above the vapour

pressure (p

Vapour

) of the operating fluid

(=> p

1 min

≤ p

Vapour

+ 50 mbar) or when there are

changes in the operating conditions (media,

temperatures), consult the manufacturer.

Concerning 5 Installation

Concerning 5.1

Installing the unit

Conditions for setting up the system:

The type of protection on the drive motor must

correspond to the ambient atmosphere

requirements in accordance with guideline

94/9/EG.

The equipment and components added to the

unit must also correspond to the requirements for

device group II category in guideline 94/9/EG.

The equipment and components added to the

unit must also correspond to the requirements for

device group II category in guideline 94/9/EG,

unless they have their own ignition source. The

bleeder resistance for each installed accessory or

attached part as well as for the unit must have

< 10

6

Ohm to ground when assembled!

Concerning 5.2

Connecting the unit

mechanically

...............

Concerning 5.2.1 Connecting the suction and

discharge branches

In order to prevent overloading from throttle on

the discharge side, pressure monitoring (G2,

Fig. 1, page 6) must be installed on the other side

of the unit’s gas output flange. If the maximum

outlet pressure p

2 max

specified in the

610.44440.40.000 operating manual section 3.3,

“Operating conditions, normal operation” is

exceeded, the equipment must switch off.

If operating with cavitation protection, the line

must have sufficient electrical conductivity

(bleeder resistance < 10

6

Ω).

Foreign bodies must be prevented from getting

into the pump.

If there is danger of foreign bodies getting in

while the pump is operating or switched off,

suitable filters must be attached.

Concerning 5.2.3 Connecting up system

components

...............

The built-in monitoring systems must be fully

functional independently from one another. The

systems must also remain independent if

computer-programmed controls are used.

Monitoring of continual operating liquid feed

Monitoring of continual operating liquid feed is

compulsory. Monitoring can be ensured by the

following alternative systems:

a) Measuring the operating liquid volume flow

(F1, Fig. 1, page 6) with suitable sensor and

analysis device. Switching commands must

operate directly on the switches.

When using a volume flow device which can

block, an additional redundant monitoring

system must be provided.

Specifications regarding failure safety as well

as calibration and servicing intervals should

be taken from the monitoring device operating

manual.

Disconnection condition:

Volume flow ≤ 50 % of the design operating

fluid flow

(see 610.44440.40.000 operating manual

section 3.3, “Operating conditions, normal

operation”)