Gorman−rupp msha pump inspection form – Gorman-Rupp Pumps SM4G1-X30 460/3 1002211 thru 1241783 User Manual

Page 7

OM−04417

SM SERIES

PAGE B − 2

INSTALLATION

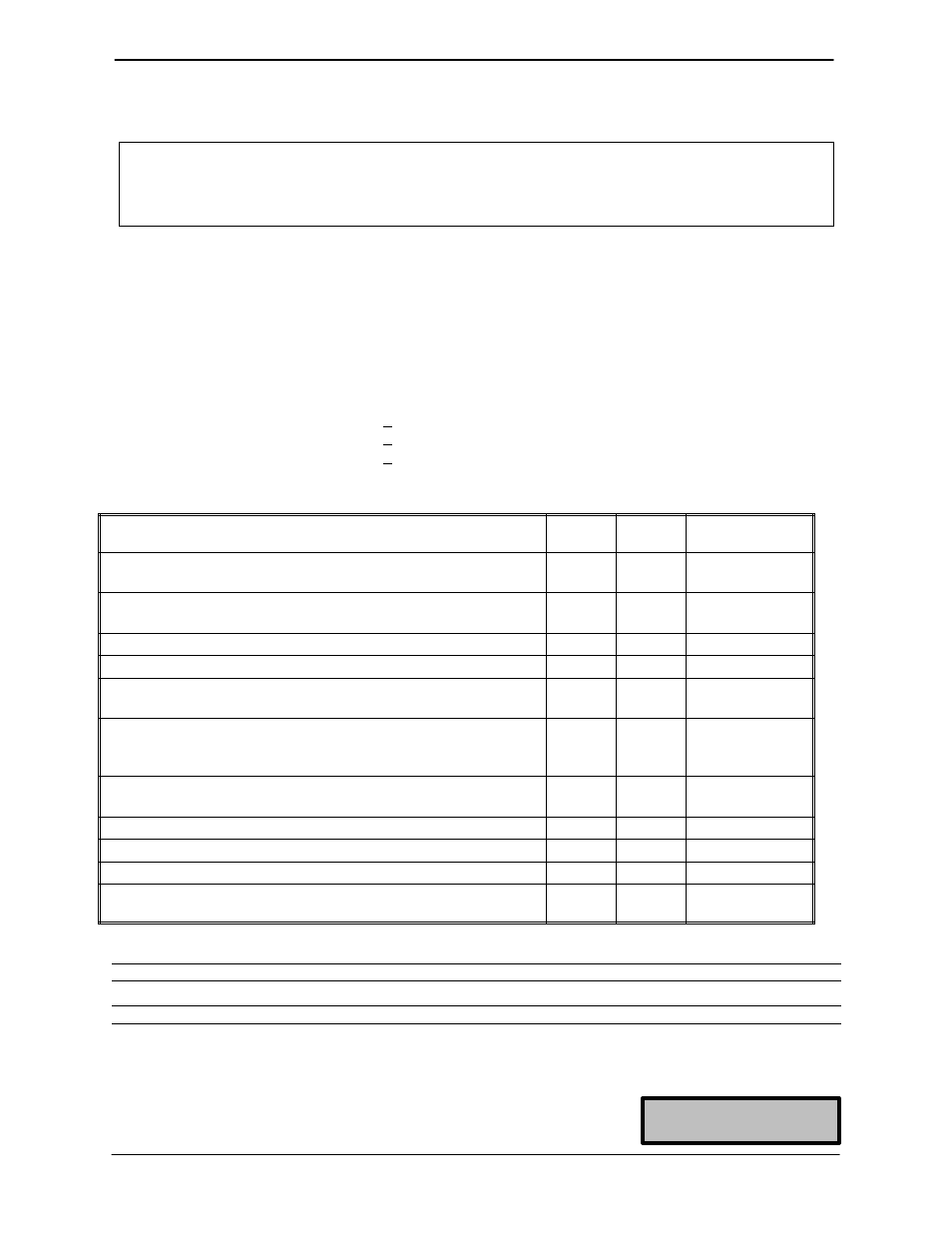

GORMAN−RUPP MSHA PUMP INSPECTION FORM

INSPECTOR____________________________

DATE____________

MODEL NO.____________________________

SERIAL NO.____________

UNIT ELECTRICAL RATING:

H.P.________,

VOLTS________,

PUMP AMPS________, HERTZ________

STARTER X/P NO:

XP3026−1 (CONTROL WITHOUT FLOAT)

OR

18−XPA040007−0 (CONTROL WITH FLOAT)

MOTOR CABLE:

___No. 12; 7 Conductor; Type SPC; .89 + .03 O.D.; Heavy Jacketed; Royal – MSHA 122;

___No. 8; 9 Conductor; Type SPC; 1.05 + .03 O.D.; Heavy Jacketed; Royal – MSHA 122;

___No. 6; 9 Conductor; Type SPC; 1.25 + .04 O.D.; Heavy Jacketed, Royal – MSHA 122;

Length______________________

ITEM

AREA OF INSPECTION

ACC.

REJ.

CORRECTED

1.

Are lockwashers (or equivalent) provided for all explo-

sion proof enclosure fastenings?

2.

Are all plane joints securely fastened so that a .005−inch

feeler gauge cannot be inserted?

3.

Is motor plug secured with lock clip?

4.

Are all electrical connections secure?

5.

Are all electrical connections insulated where necessary

and per appropriate drawing?

6.

Are packing glands properly packed so that 1/8−inch

clearance remains between packaging nut and stuffing

box?

7.

Are packing nut and cable grip secured with lock wire and

lead seal?

8.

Was pump leak tested?

9.

Was pump and control electrically tested?

10.

Was pump water tested?

11.

Are pump, cable, and control assembled together properly

per appropriate drawing?

Comments:

NOTE: Fill out form completely and “rejections” must be corrected and re−inspected. Inspector must

initial and date when corrective action was taken. 10/9/87

Form CD GL−02128 Rev 6/05

Doc# 152708

This form not to be revised

without approval of MSHA.

- SM4G1-X30 575/3 1002211 thru 1241783 SM4J1-X60 460/3 1004954 thru 1241784 SM4C1-X10 460/3 1136140 and up SM4C1-X10 575/3 1136140 and up SM4C18-X10 460/3 1136140 and up SM4C18-X10 575/3 1136140 and up SM4C65-X10 460/3 915775 and up SM4C65-X10 575/3 915775 and up SM4D1-X10 460/3 1094445 and up SM4D1-X10 575/3 1094445 and up SM4D65-X10 575/3 915775 and up SM4D65-X10 460/3 915775 and up