Gorman-Rupp Pumps S8B1-E100 460/3 1432260 and up User Manual

Page 43

OM-06259

S SERIES PUMPS

PAGE E - 17

MAINTENANCE AND REPAIR

Heat the upper bearing (31) to a uniform tempera

ture no higher than 250

_F (120_C). Slide the bear

ing onto the shaft until it is fully seated against the

shaft shoulder. Do this quickly, in one continuous

motion, to prevent the bearing from cooling and

sticking on the shaft.

Use caution when handling hot bear

ings to prevent burns.

Clean the bearing cap (17) and position it over the

lower bearing (47) before heating.

NOTE

Position the cap on the bearing, so that when in

stalled on the shaft, the bearing will be positioned

as indicated in Figure E-4.

Heat the lower bearing and cap to a uniform tem

perature no higher than 250

_F (120_C). Slide the

assembled cap and bearing onto the shaft until the

bearing is fully seated against the shaft shoulder.

Do this quickly, in one continuous motion, to pre

vent the bearing from cooling and sticking on the

shaft.

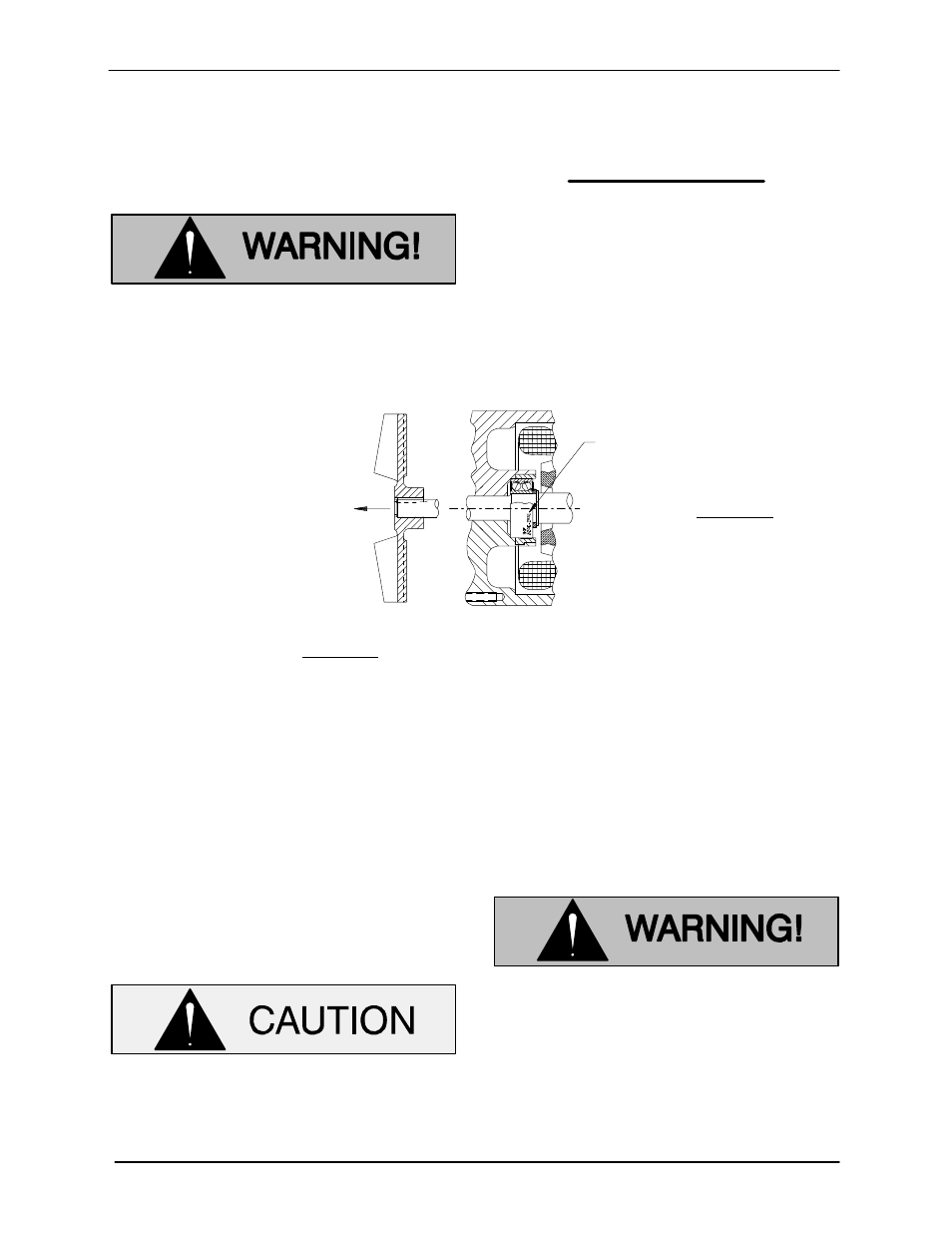

DIRECTION OF

THRUST

PART NUMBER MARKINGS ARE

LOCATED EITHER ON BEARING

O.D. (OFFSET FROM CENTER) OR

ON SIDE FACE OF BEARING. FOR

EITHER TYPE, POSITION BEAR

ING WITH TEXT AWAY FROM IM

PELLER.

INSTALLATION OF SKF 5200 AND 5300 SERIES BEARINGS

NOTE:

THIS BEARING IS MANUFACTURED WITH TWO SEALS OR SHIELDS. WHEN INSTALLED ON THE SHAFT, THE MAN

UFACTURER'S PART NUMBER DESCRIPTION (LOCATED ON SIDE FACE OF BEARING OR BEARING O.D.) MUST BE

LOCATED WITH THE TEXT AWAY FROM THE IMPELLER.

Figure E-4. Bearing Installation

After the bearings have been installed and allowed

to cool, check to ensure that they have not moved

out of position in shrinking. If movement has oc

curred, use a suitable sized sleeve and a press to

reposition the bearings. Make certain that they are

seated squarely against the shaft shoulders.

If heating the bearings is not practical, use a suit

able sized sleeve and an arbor (or hydraulic) press

to install the bearings on the shaft.

When installing the bearings onto the

shaft, never press or hit against the outer

race, balls, or ball cage. Press only on the

inner race.

Rotor Installation

(Figure E-1)

Use fresh solvent to clean all gasket and O‐ring

surfaces of the motor housing (18) and intermedi

ate (48), completely removing any old gasket and

cement material. Inspect the sealing surfaces for

burrs, nicks and pits which could cause a poor

seal. Repair or replace as require.

Most cleaning solvents are toxic and

flammable. Use them only in a well ven

tilated area free from excessive heat,

sparks, and flame. Read and follow all

precautions printed on solvent contain

ers.

Carefully ease the rotor (39), bearing cap (17) and

assembled bearings (31 and 47) into the interme