Gorman-Rupp Pumps S4A1-E25 460/3 1396155 and up User Manual

Page 35

OM-06098

S SERIES PUMPS

PAGE E - 9

MAINTENANCE AND REPAIR

Inspect the rotor shaft (40) for damaged threads,

scoring, or nicks. Remove nicks and burrs with a

fine file or hand honing stone to restore original

contours. If the shaft is bent or severely damaged,

the rotor and shaft must be replaced as an assem

bly (see MOTOR DISASSEMBLY).

Neither of the shaft seal assemblies (3 or 4) should

be reused because wear patterns on the finished

faces cannot be realigned during reassembly. This

could result in premature failure. If necessary to re

use an old seal in an emergency, carefully wash

all metallic parts in fresh cleaning solvent and allow

to dry thoroughly.

Handle the seal parts with extreme care to prevent

damage. Be careful not to contaminate the preci

sion finished faces; even fingerprints on the faces

can shorten seal life. If necessary, clean the faces

with a non‐oil based solvent and a clean, lint‐free

tissue. Wipe lightly in a circular pattern to avoid

scratching the faces.

Inspect the seal components for wear, scoring,

grooves, and other damage that might cause leak

age. If any components are worn, replace the com

plete seal; never mix old and new seal parts.

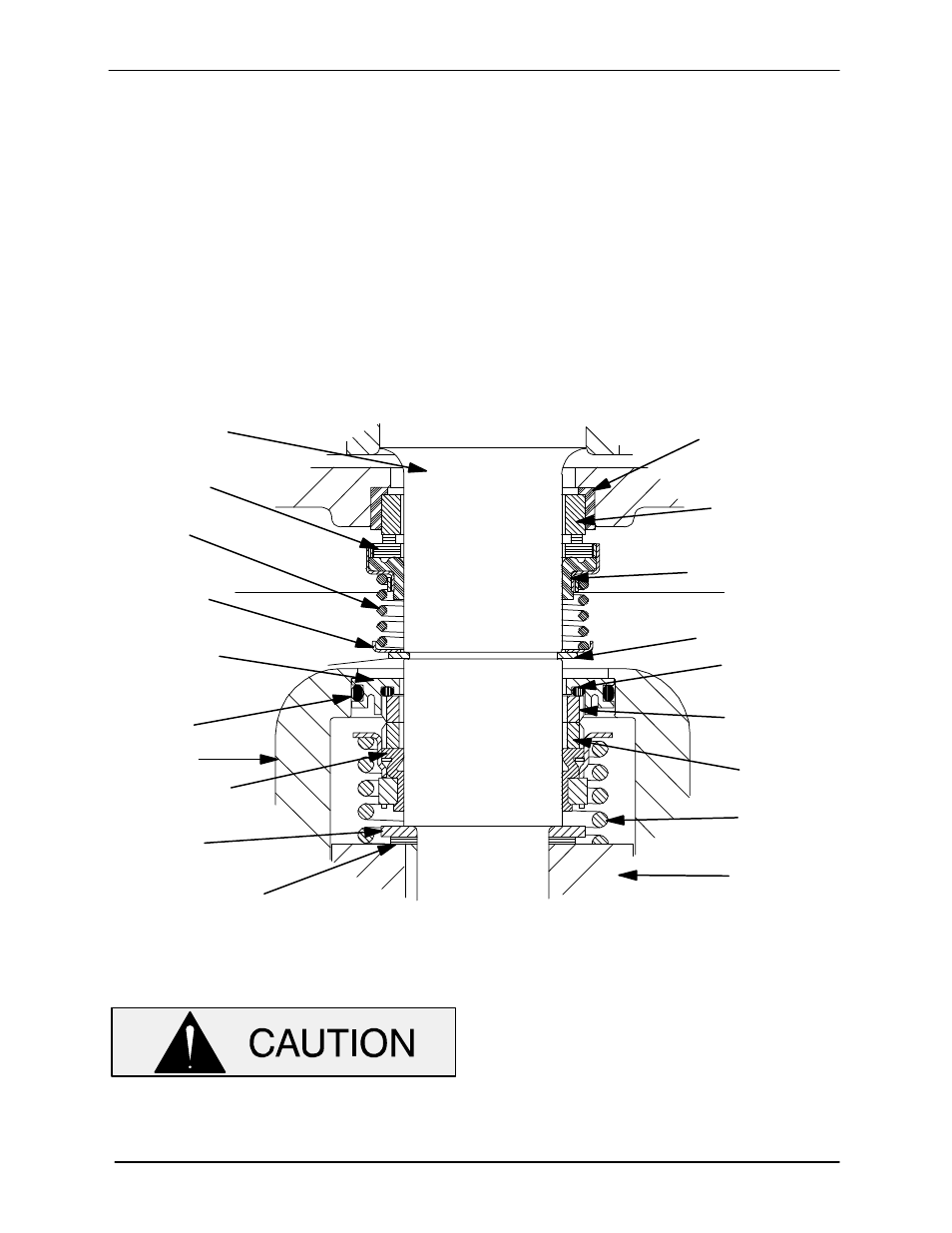

Install the shaft seals as illustrated in Figure E-3.

STATIONARY

SEAL SEAT

SPRING

IMPELLER

BELLOWS AND

RETAINING ASSY

ROTOR

SHAFT

ROTATING

ELEMENT

STATIONARY

ELEMENT

SEAL

RETAINING RING

DIFFUSER

STATIONARY

SEAL SEAT

SPRING

BELLOWS AND

RETAINING ASSY

IMPELLER

WASHER

ROTATING

ELEMENT

SPRING

RETAINER

O‐RING

STATIONARY

ELEMENT

SHIM SET

O‐RING

Figure E-3. Upper And Lower Seal Assemblies

This seal is not designed for operation at

temperatures above 122

_ F (50_ C). Do not

use at higher operating temperatures.

Upper Seal Installation

(Figures E-1 and E-3)

Do not unwrap a new seal assembly until time of

installation. Cleanliness of seal components is criti

cal, especially the seal faces.