Troubleshooting - section d, Troubleshooting chart – Gorman-Rupp Pumps S4A1-E25 460/3 1396155 and up User Manual

Page 23

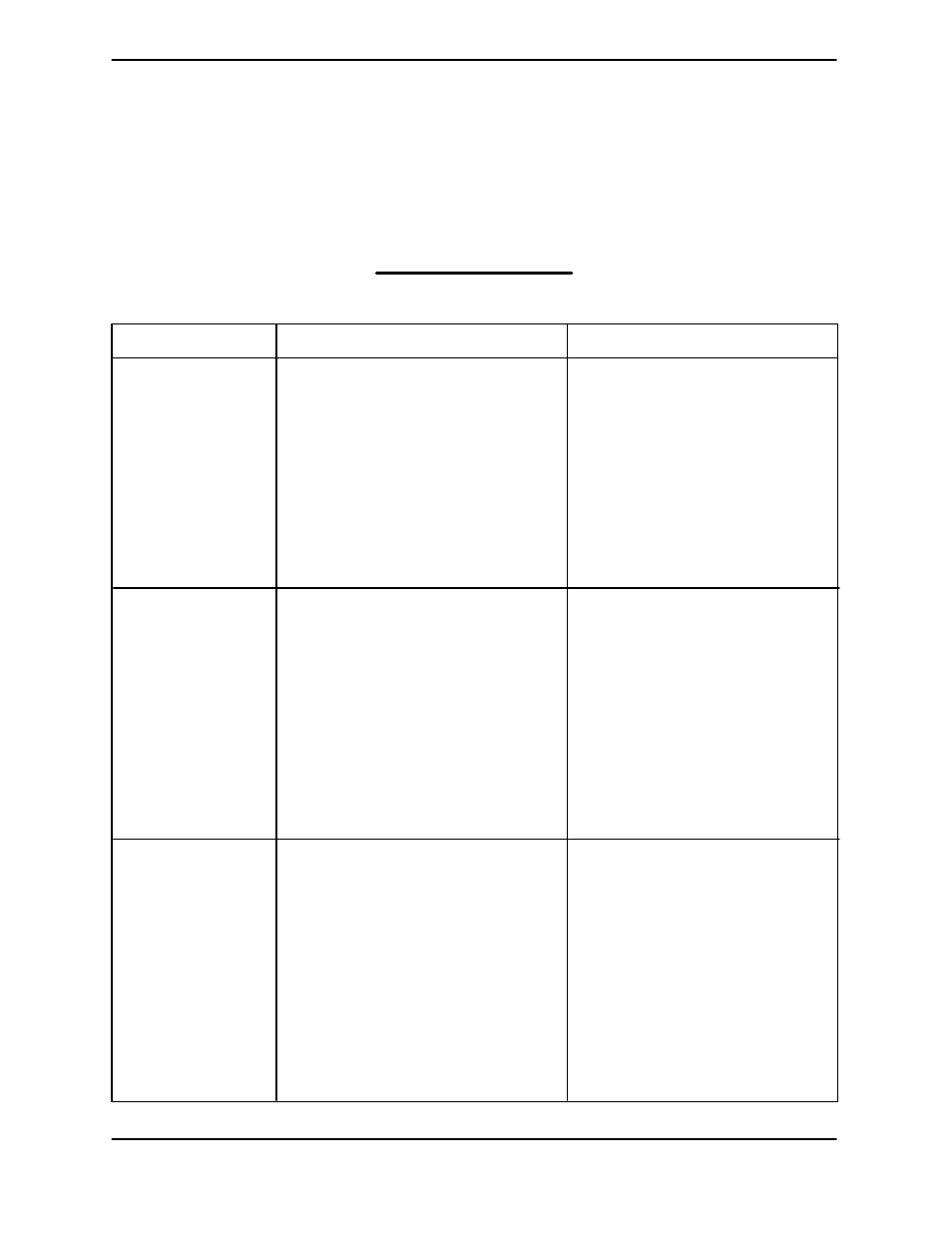

TROUBLE

POSSIBLE CAUSE

PROBABLE REMEDY

PUMP FAILS TO

START, OVER

LOAD UNIT NOT

TRIPPED (MANU

AL MODE).

Power source incompatible with con

trol box.

Correct power source.

No voltage at line side of circuit

breaker.

Check power source for blown fuse,

open circuit breaker, broken lead or

loose connections.

Open circuit in motor windings or

power cable.

Check continuity.

Defective motor power cable.

Replace cable.

Defective motor.

Check for and replace defective mo

tor components.

PUMP FAILS TO

START, OVER

LOAD UNIT NOT

TRIPPED (AUTO

MATIC MODE).

Liquid level device or control circuits

improperly connected to main con

trol box.

Check wiring diagrams: cor

rect or tighten connections.

Level sensing device(s) improperly

positioned.

Position device(s) at proper

level.

Level sensing device(s) fouled with

mud or foreign material.

Clean sensing device(s).

Float type sensing device(s) tangled

or obstructed.

Check installation for free

movement of float.

Defective liquid level sensing de

vice(s) or control panel.

Repair or replace defective unit(s).

OVERLOAD UNIT

TRIPS

Low or high voltage, or excessive

voltage drop between pump and

control box.

Measure voltage at control box.

Check that wiring is correct type,

size, and length (see Field Wiring

Connection, Section B).

Defective insulation in motor wind

ings or power cable; defective wind

ings.

Check insulation resistance; check

continuity.

Impeller jammed due to debris or in

sufficient clearance.

Disassemble pump and check im

peller.

Bearing(s) frozen.

Disassemble pump and check bear

ing(s).

S SERIES PUMPS

OM-06098

PAGE D - 1

TROUBLESHOOTING

TROUBLESHOOTING - SECTION D

Review all SAFETY information in Section A.

NOTE

Many of the probable remedies listed in the TROU

BLESHOOTING CHART require use of electrical

test instruments; for specific procedures, see

ELECTRICAL TESTING at the end of the chart.

TROUBLESHOOTING CHART