Gorman-Rupp Pumps S4A1-E25 460/3 1396155 and up User Manual

Page 11

S SERIES PUMPS

OM-06098

PAGE B - 3

INSTALLATION

Positioning the Pump

NOTE

Before installing and operating the pump, check

the direction of impeller rotation to ensure that the

pump is properly wired at the control box. See IM

PELLER ROTATION, Section C.

The pump is designed to operate fully or partially

submerged. The rotating parts are oil lubricated,

and the motor is cooled by a constant flow of liquid

or air discharged through internal passages.

As a safeguard against rupture or explosion due to

heat, models equipped with oil‐lubricated motors

are fitted with a pressure relief valve which will open

if vapor pressure within the pump motor reaches a

critical point.

The pump will operate if positioned on its side, but

this is not recommended because the motor

torque could cause the pump to roll during opera

tion.

The pump should be independently secured and

supported by the lifting device fitted on the pump.

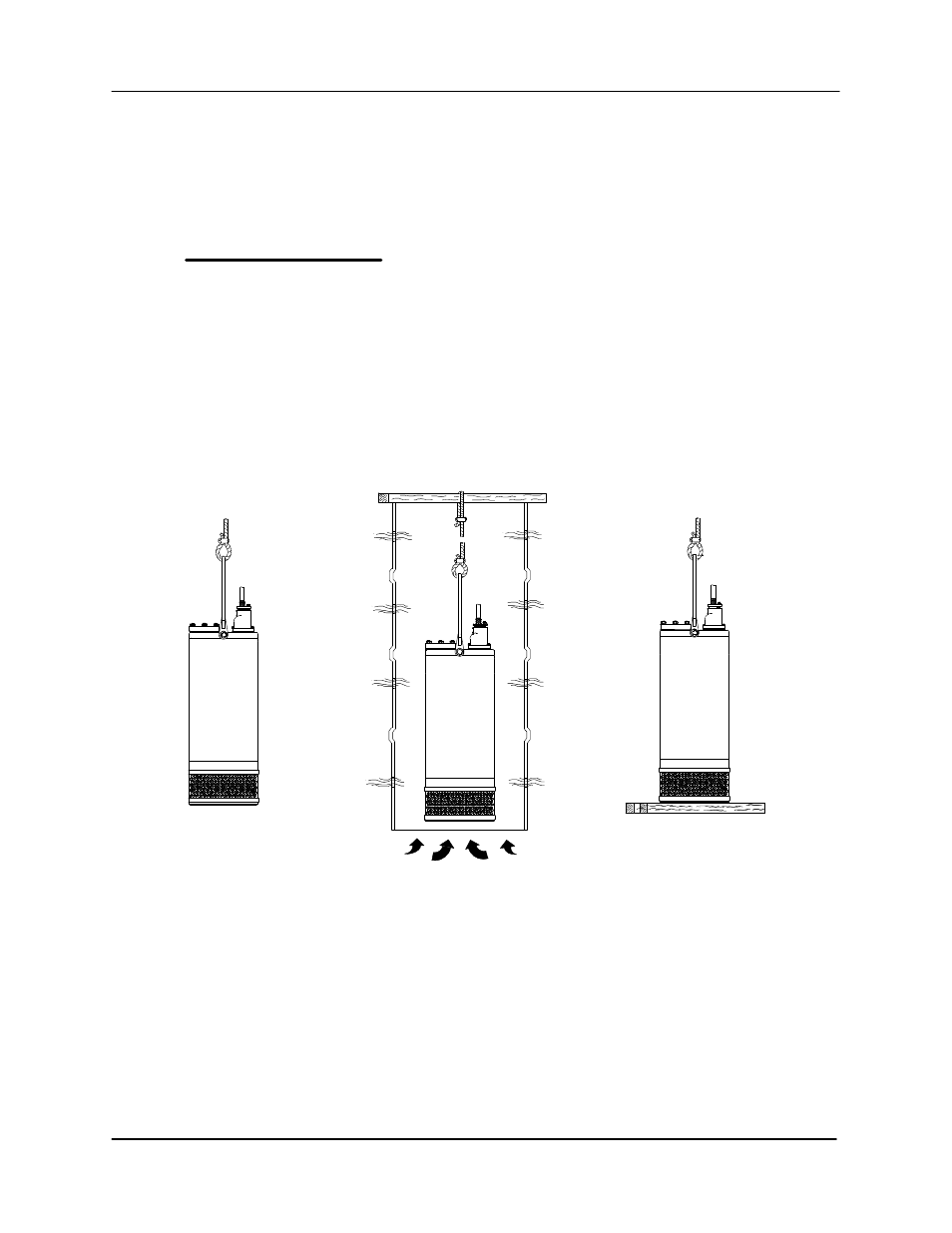

If the application involves a lot of debris, protect the

pump from excessive wear and clogging by sus

pending it in a perforated barrel or culvert pipe. If

the bottom is heavily sludge‐covered, rest the

pump on support blocks or suspend it from a raft

or similar device near the surface of the liquid. See

Figure B-1 for typical pump installations.

All liquid entering the pump must pass through a

strainer screen. Any spherical solids which pass

through the screen will pass through the pump.

BY BAIL

IN PERFORATED CULVERT PIPE

ON SUPPORTS

Figure B-1 Typical Pump Installations

Piping

No suction piping is required in a standard installa

tion.

These pumps are provided with a suction strainer

to prevent large solids from clogging the impeller.

If required, the strainer can be removed and the

pump suction “staged” to the discharge of another

pump, allowing one pump to feed the other on high

discharge head applications.

To determine the size of the discharge connection,

see Table B-1, Pump Specifications. Either

hose or rigid pipe may be used. To facilitate mobil

ity and maintenance, it is recommended that the

discharge line be fitted with a quick disconnect fit