Gorman-Rupp Pumps SE1 1/2A3 115V 1P 1483930 and up User Manual

Page 38

OM−06488

SE SERIES

MAINTENANCE AND REPAIR

PAGE E − 14

certain the terminal makes good contact with the

plate.

Position the head (27) on the motor housing (10)

and secure with the hardware (19 and 20).

See PUMP END REASSEMBLY to reassemble the

pump end components.

FINAL ASSEMBLY

If the discharge flange (5) was removed from the

pump casing, replace the discharge flange gasket

(4). Secure the flange with the hardware (6 and 7).

VACUUM/PRESSURE TESTING

To ensure the water-tight integrity of the pump, it is

recommended that the motor and seal cavities be

vacuum and pressure tested any time the seal and/

or motor are serviced. The seal cavity must be

pressurized to prevent separation of the seal faces

or unseating the stationary seal seat between the

seal and motor cavities. Use a manometer with a

range up to 30 inches of mercury to perform the

vacuum test. Do not use a vacuum gauge. Vacu-

um gauges are not sensitive enough to detect mi-

nor leaks.

Drain all of the oil from both the seal and motor

cavities before performing the test. Oil within the

motor cavity will be drawn into the system, result-

ing in damage to the vacuum pump or manometer.

It is recommended that a vacuum pump be used to

draw the vacuum on the motor cavity. If a vacuum

pump is not available, a compressor/venturi sys-

tem may be used. If the compressor/venturi cannot

draw the vacuum level shown in Table E−1, draw

the motor cavity vacuum down as far as the system

will allow, then pressurize the seal cavity so the dif-

ferential between the two cavities is the same as

the differential between the readings shown in the

table.

If a compressor/venturi system is used, install full-

closing ball-type shutoff valves with quick-discon-

nect fittings in the pipe plug holes in both the motor

and seal cavities. This will allow the pressure (or

vacuum) to be maintained while using the com-

pressor to perform the second portion of the test.

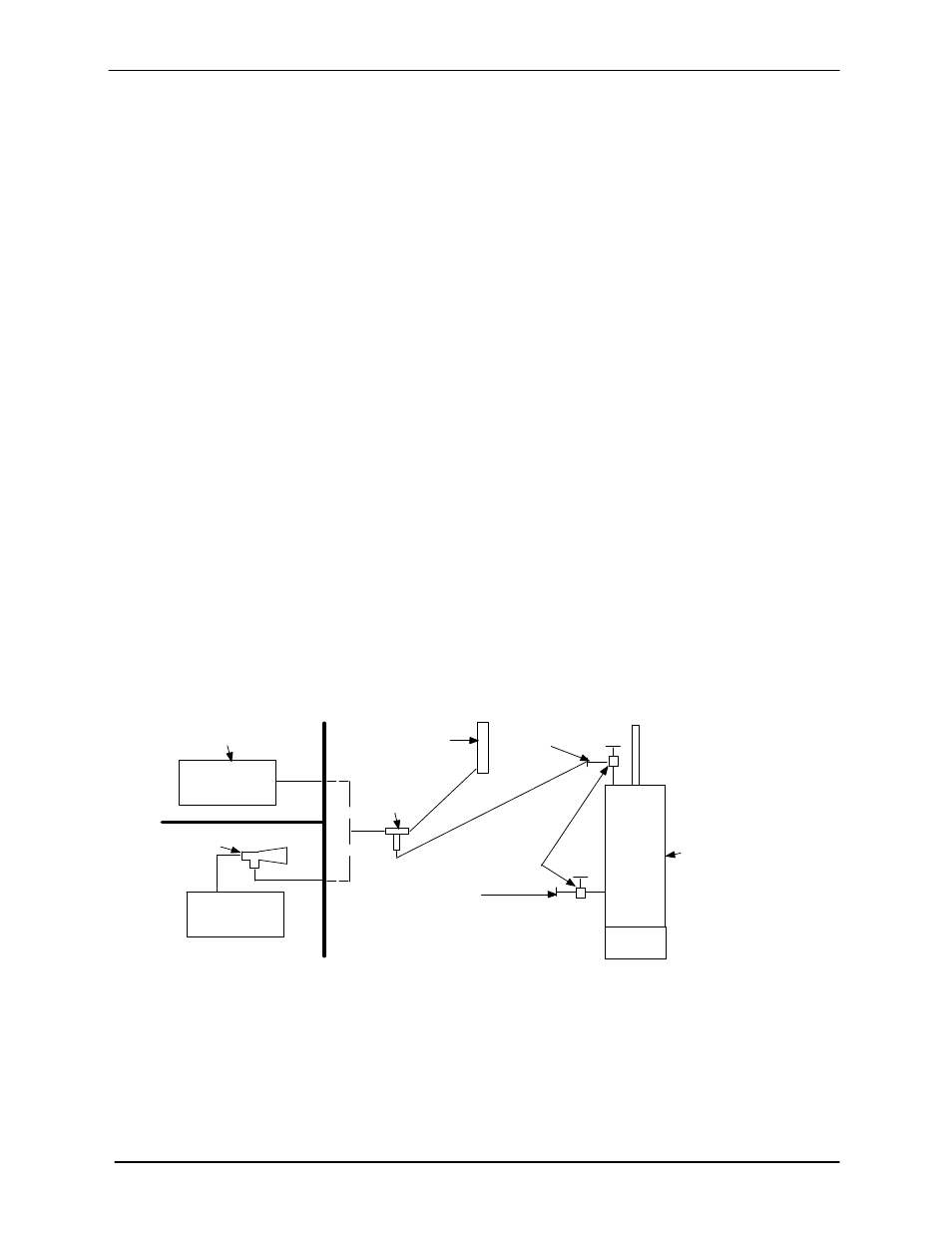

Figure E−3 shows a simple schematic for setting

up either a vacuum pump or a venturi/compressor

test system.

ООО

ООО

ООО

Tee

Manometer

Vacuum Pump

Submersible

Pump

Full-Closing

Ball-Type

Shutoff Valve

Quick Disconnect

Fitting

Quick Disconnect

Fitting

Air Compressor

Venturi

Vacuum Test

Motor Cavity

Use Compressor

to Pressure Test

Seal Cavity

Figure E−3. Vacuum/Pressure Test System

Table E−1 shows the motor cavity vacuum and

seal cavity pressure readings for the test, and the

duration to maintain each reading. Any change in

the readings during the test indicates a leak which

must be identified and corrected before putting the

pump back into service.

Table E−1. Vacuum/Pressure Test Data