Gorman-Rupp Pumps PA4B60-4045H 1497876 and up User Manual

Page 40

PA SERIES

OM−06228

MAINTENANCE & REPAIR

PAGE E − 20

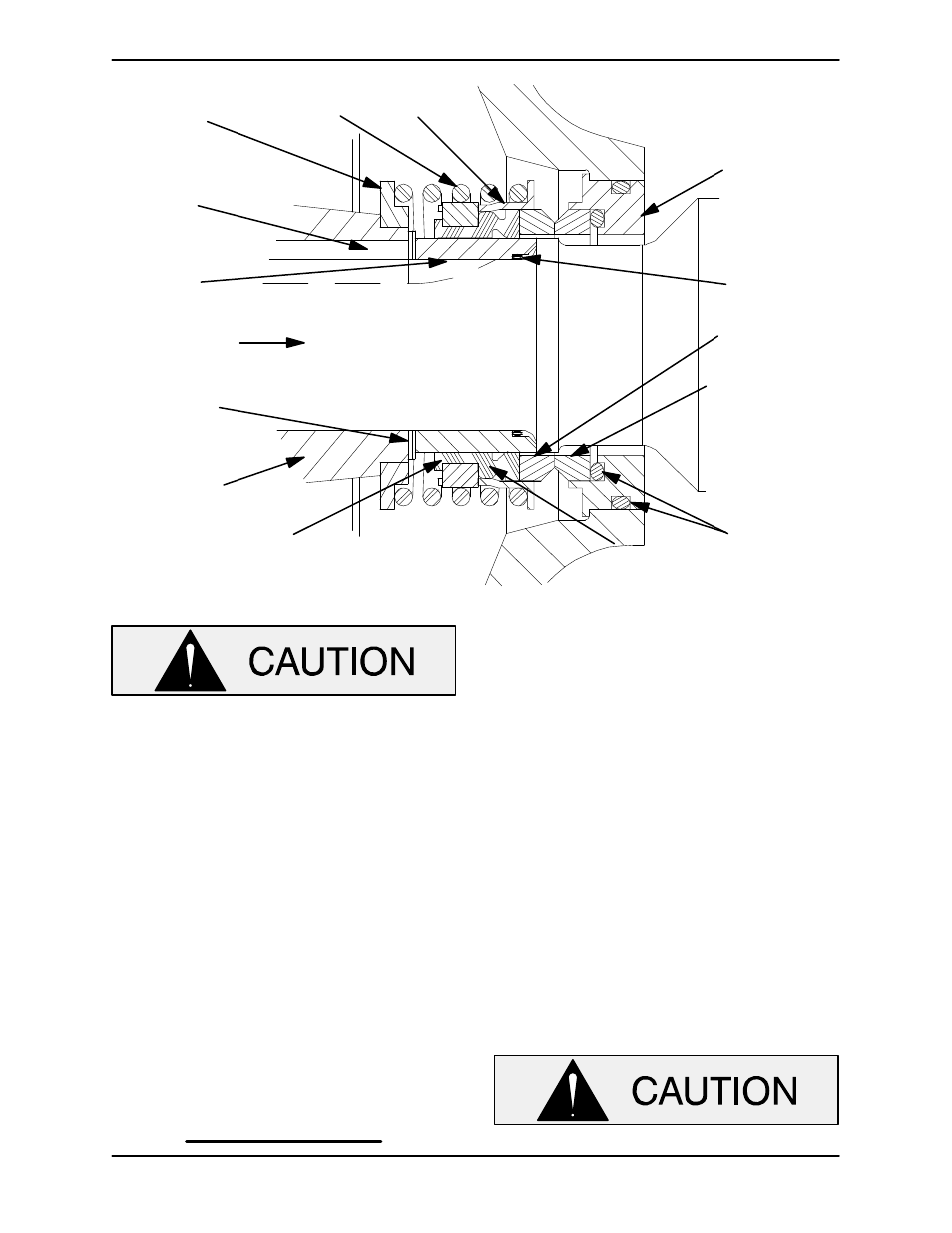

IMPELLER

SHAFT

SPRING

IMPELLER

RETAINER

BELLOWS

ROTATING

ELEMENT

STATIONARY

SEAT

SHAFT

SLEEVE

SHAFT

KEY

IMPELLER

SHIMS

SHAFT

SLEEVE

O-RING

O-RINGS

SPRING

HOLDER

STATIONARY

ELEMENT

Figure 9. 46512−048 Seal Assembly

This seal is not designed for operation at

temperatures above 160

_ F (71_ C). Do

not use at higher operating temperatures.

Inspect the pump casing and impeller shaft for

burrs or sharp corners and remove any that exist.

With the stationary seat O-ring lubricated and

installed in the stationary seat, press the stationary

seat and element into the pump casing until it seats

squarely against the bore shoulder. Be careful not

to damage the stationary element. A push tube cut

from a length of plastic pipe would aid this installa-

tion. The O.D. of the pipe should be approximately

the same diameter as the O.D. of the seal spring.

NOTE

If the pump casing has not been installed, position

the casing over the shaft and against the intermedi-

ate, using caution not to damage the seal stationary

seat and element. Secure the casing to the inter-

mediate with the hardware (30 and 31).

Lubricate the shaft sleeve O-ring (46) and slide it

onto the shaft.

Subassemble the rotating element into the retainer

and bellows. Use even pressure to carefully press

this subassembly onto the lubricated sleeve (45)

until the seal face is just flush with the chamfered

end of the sleeve.

Slide the assembled sleeve and rotating portion of

the seal onto the shaft until the seal faces contact.

Continue to push the sleeve through the seal until it

seats squarely against the shaft shoulder.

Install the seal spring and spring holder (47).

Impeller Installation

(Figure 4)

If the balance ring (35) was removed, press the re-

placement ring into the pump casing as described

in Pump Casing Installation.

The balance ring must seat squarely in the