Installation, Preinstallation inspection – Gorman-Rupp Pumps 4D-X3 1P User Manual

Page 7

D SERIES

OM--01515

PAGE B -- 1

INSTALLATION

INSTALLATION --- SECTION B

Review all SAFETY information in Section A.

Since pump installations are seldom identical, this

section offers only general recommendations and

practices required to inspect, position, and ar-

range the pump and piping.

For further assistance, contact your Gorman-Rupp

distributor or the Gorman-Rupp Company.

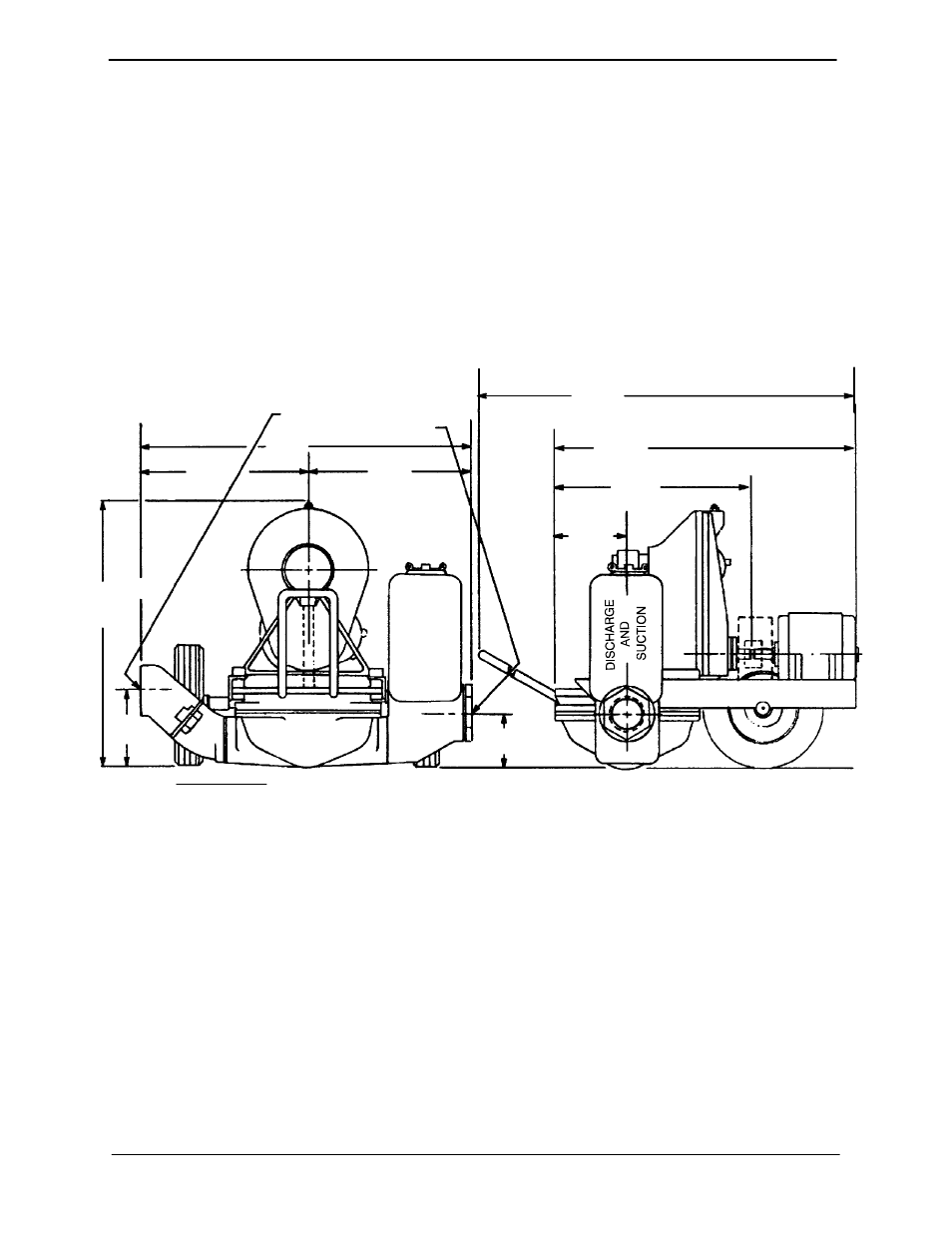

Pump Dimensions

See Figure 1 for the approximate physical dimen-

sions of this pump.

OUTLINE DRAWING

MOTOR FRAME 182T AND 184T

5,31

[134,9]

7.31

[185,7]

19.69

[500,1]

32,31

[820,7]

50.69

[1287,5]

4” N.P.T. DISCHARGE

3” (OR 4”) N.P.T. SUCTION

33.88

[860,6]

16.88

[428,8]

17.00

[431,8]

APPROX

26.62

[676,1]

7.00

[177,8]

DIMENSIONS:

INCHES

[MILLIMETERS]

53.94

[1370,1]MOTOR FRAME 213 AND 215

MOTOR FRAME 182T AND 184T

34,94

[887,5] MOTOR FRAME 213 AND 215

Figure 1. 4D Electric Motor Driven Pumps

PREINSTALLATION INSPECTION

The pump assembly was inspected and tested be-

fore shipment from the factory. Before installation,

inspect the pump for damage which may have oc-

curred during shipment. Check as follows:

a. Inspect the pump for cracks, dents, damaged

threads, and other obvious damage.

b. Check for and tighten loose attaching hard-

ware. Since gaskets tend to shrink after dry-

ing, check for loose hardware at mating sur-

faces.

c. Carefully read all tags, decals, and markings

on the pump assembly, and perform all duties

indicated.

d. Check levels and lubricate as necessary. Re-

fer to

LUBRICATION in the MAINTENANCE

AND REPAIR section of this manual and per-

form duties as instructed.

e. If the pump and motor have been stored for

more than 12 months, some of the compo-

nents or lubricants may have exceeded their

maximum shelf life. These

must be inspected