Gorman-Rupp Pumps 612L20-B 814882 and up User Manual

Page 24

OM−01395

60 SERIES

MAINTENANCE & REPAIR

PAGE E − 5

Support the pump casing using a suitable hoist

and sling.

Remove the hardware (5 and 38) securing the

pump casing to the pedestal.

Pull the pump casing straight away from the ped-

estal to prevent binding on the impeller. Remove

the casing gasket (36) and clean the contacting

surfaces.

Impeller Removal

Before removing the impeller, remove the bottle oil-

er (9) and piping (10 and 11). Remove the seal cav-

ity drain plug (34) and drain the seal cavity oil. This

will prevent oil from escaping when the impeller is

removed.

To loosen the impeller nut, the impeller shaft must

first be disconnected from the power source. With

the power source disengaged, install the key (24)

in shaft keyway. Install a lathe dog on the drive end

of the shaft with the V" notch positioned over the

shaft key.

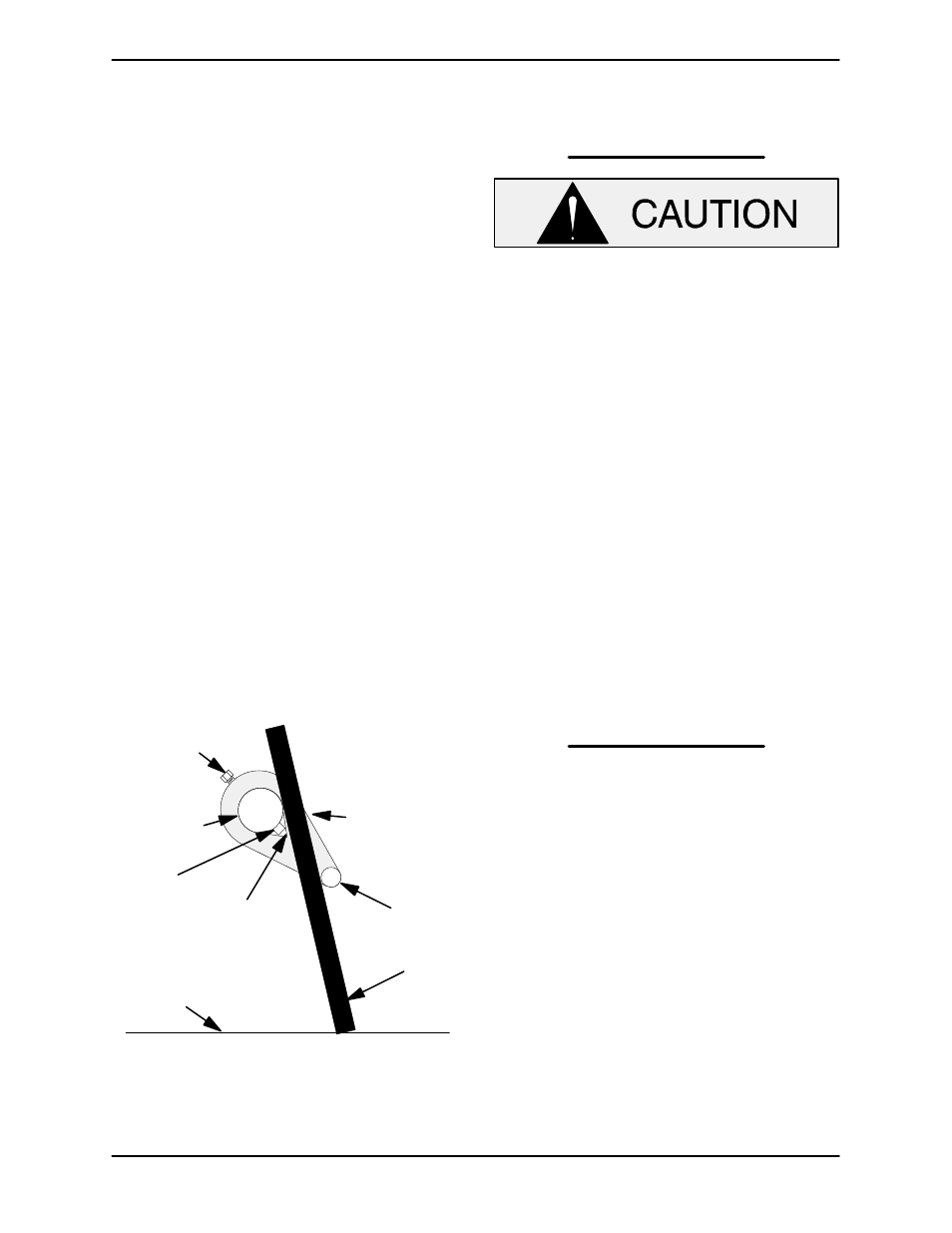

Use a long piece of heavy bar stock and the lathe

dog as shown in Figure E−2 to block shaft rotation.

Use caution not to damage the shaft or keyway.

Lathe Dog Arm

V" Notch

Shaft Key

Impeller

Shaft

Lathe Dog

Setscrew

Heavy

Bar Stock

Work Surface

Figure E−2. Blocking Shaft Rotation

Loosen the two setscrews (41) and remove the im-

peller nut (40).

NOTE

If necessary, heat the impeller with a torch to aid in

the removal.

The impeller is very heavy and could be

damaged and/or could injure personnel if

it is dropped. Use extreme caution when

performing the following procedure to pre-

vent dropping the impeller when it breaks

loose from the shaft.

The impeller is secured to the shaft by the woodruff

key (50) and a taper fit.To remove the impeller, in-

stall two 3/8-16 UNC capscrews (not supplied) in

the tapped holes in the impeller. Use a gear puller

to preload the impeller. Strike the gear puller shaft

with a hammer to break the impeller loose. Re-

move the impeller and woodruff key.

NOTE

An alternate method of removing the impeller is to

install two wedges 180

_ apart between the impeller

and the seal plate. Tap the wedges alternately until

the impeller breaks loose. If necessary, position a

piece of round bar stock against the end of the im-

peller shaft and strike the bar stock with a hammer

to loosen the taper fit between the impeller and the

shaft.

The wear ring (43) is a shrink fit on the impeller.

Heat the wear ring to remove it from the impeller.

Use caution not to damage the impeller. Pry or

carefully grind the wear ring off the impeller.

Seal Removal

This pump is designed with two seals; a primary

mechanical seal (3) located directly behind the im-

peller and a secondary oil seal (33) located at the

back of the seal plate (35). If the liquid being

pumped leaks past the oil seal, both seals should

be replaced immediately.

Remove the air vent and piping (6, 7 and 8) from

the seal plate (35).

Remove the seal spring. Apply oil to the shaft in the

area of the mechanical seal bellows. Slide the ro-

tating portion of the seal off the shaft.