Gorman-Rupp Pumps 54J20-B 1410811 and up User Manual

Page 32

50 SERIES

OM-01342

MAINTENANCE & REPAIR

PAGE E - 10

The wear ring must seat squarely in the

casing bore or binding and/or excessive

wear will result.

Inspect the impeller, and replace it if cracked or

badly worn. Install the same thickness of impeller

shims (44) as previously removed and screw the

impeller onto the shaft until tight.

For maximum pump efficiency, the impeller should

be centered within the volute scroll.

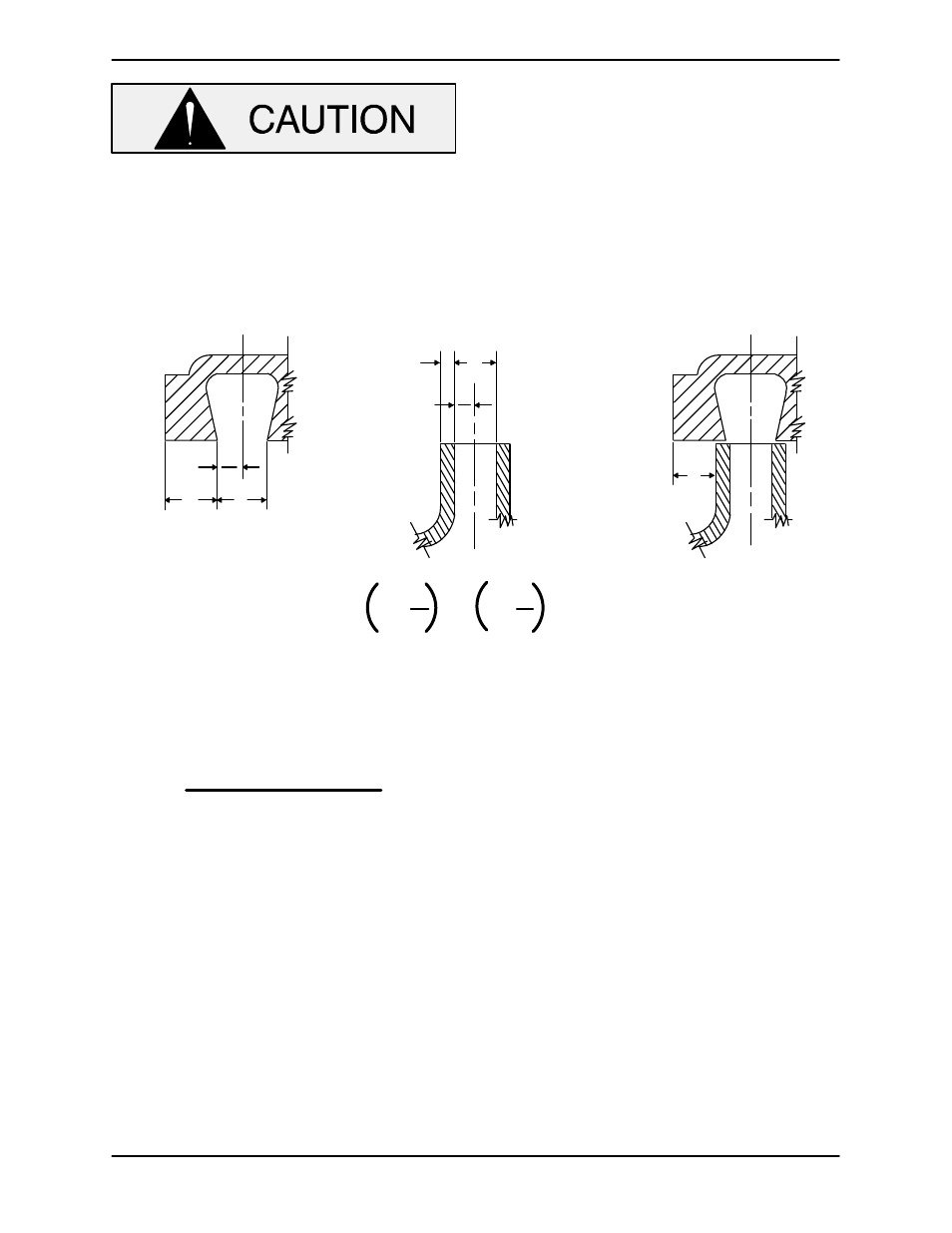

To verify the impeller positioning, measure the

pump casing and impeller as shown in Figure 5.

Use these measurements to calculate the required

impeller location (dimension E). Add or remove im

peller adjusting shims until dimension E is ob

tained.

D

B

2

A

B

2

C

D

E

Step 2

Step 1

Step 3

A+

B

2

C+

D

2

E

=

-

Figure 5. Centering Impeller Within Volute Scroll

NOTE

After the impeller has been properly positioned,

check for free rotation. Correct any scraping or

binding before further reassembly.

Replace the cover plate gasket (38). Apply `Loctite

Thread Sealant' or equivalent compound to the

studs (39) and attach the cover plate (41) to the

pump casing using the nuts (40). Make sure the

jacking screws (42) do not interfere with the cover

plate seating.

Turn the shaft by hand to make sure that the impel

ler is not binding or scraping.

Final Pump Assembly

Be sure the pump assembly is securely mounted

to the power source and base.

Install the suction and discharge lines and open all

valves. Make certain that all piping connections are

tight, properly supported and secure.

Be sure the pump and power source have been

properly lubricated, see LUBRICATION.

Refer to OPERATION, Section C, before putting

the pump back into service.

LUBRICATION

Seal Assembly

Fill the seal bottle oiler (14) with SAE No. 30 non‐

detergent oil. Check the oil level regularly and keep

the bottle full.

Bearings

The bearing housing was fully lubricated when

shipped from the factory. Check the oil level regu