Gorman-Rupp Pumps 54J20-B 1410811 and up User Manual

Page 27

OM-01342

50 SERIES

MAINTENANCE & REPAIR

PAGE E - 5

Work Surface

Lathe Dog Arm

“V” Notch

Shaft Key

Impeller Shaft

Lathe Dog

Setscrew

Heavy

Bar Stock

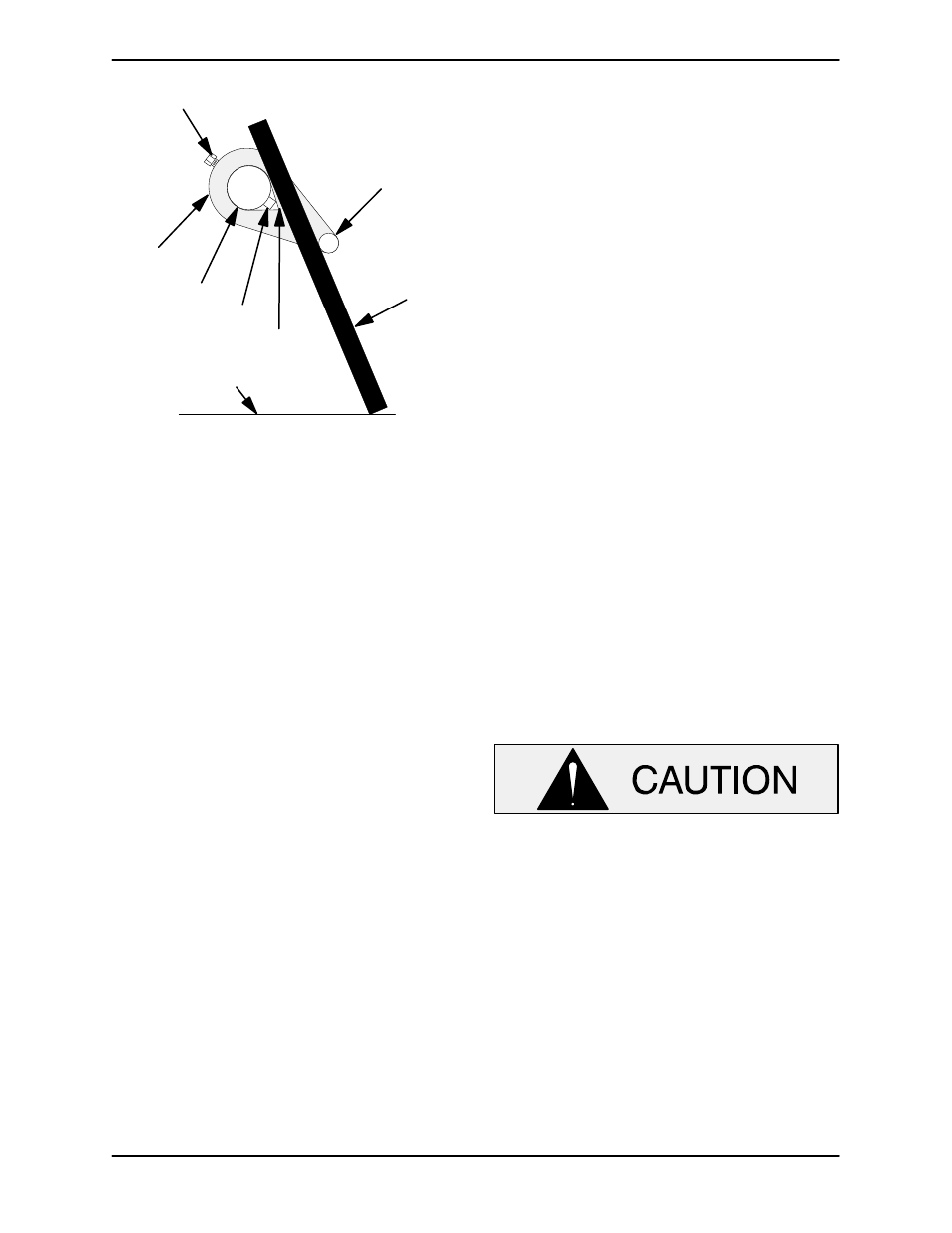

Figure 2. Loosening Impeller

The impeller bore is designed to accept a 2 inch

(50,8 mm) square block of wood or steel bar to aid

in removal of the impeller. Use an impeller wrench if

one is available. Turn the impeller counterclock

wise (when facing the impeller). When the impeller

breaks loose, remove it from the impeller shaft. Use

caution when removing the impeller; tension on

the seal spring will be released as the impeller is re

moved. Remove the lathe dog and shaft key.

Slide the impeller adjusting shims (43) off the shaft.

Tie and tag the shims or measure and record their

thickness for ease of reassembly.

With the impeller removed, inspect the wear ring

(6) for excessive wear or damage. If replacement is

required, remove the hardware (4 and 5) and install

5/16-18 UNC x 2-1/2 inch long jacking screws

(not supplied) in the threaded holes in the wear

ring. Tighten the jacking screws evenly (to prevent

binding) until the wear ring separates from the

pump casing.

Seal Removal and Disassembly

(Figures 1 and 4)

Carefully remove the assembled spring centering

washer and seal guard. Remove the seal spring.

Apply oil to the shaft and work it up under the bel

lows. Slide the rotating portion of the seal off the

shaft.

Use a pair of stiff wires with hooked ends to remove

the stationary subassembly (consisting of the sta

tionary element, seat and O‐rings).

An alternate method of removing the stationary

subassembly is to remove the seal housing (7) and

stationary subassembly from the pump casing as a

single unit.

To remove the seal housing, disengage the hard

ware (10 and 11) and install 3/8‐16 UNC jacking

screws (not supplied) in the threaded holes in the

seal housing. Tighten the jacking screws evenly to

prevent binding and separate the seal housing

from the pump casing.

Slide the seal housing and stationary portion of the

seal off the shaft (26) as a single unit. Lay the seal

housing on a flat surface with the impeller side

down and use a suitably sized dowel to press the

stationary subassembly from the seal housing.

Remove the seal housing gasket (35).

If no further disassembly is required, refer to Seal

Reassembly.

Shaft and Bearing Removal and Disassembly

When the pump is properly operated and main

tained, the shaft and bearings should not require

disassembly. Disassemble the shaft and bearings

only when there is evidence of wear or damage.

Shaft and bearing disassembly in the field

is not recommended. These operations

should be performed only in a properly

equipped shop by qualified personnel.

If not removed, remove the power source and ped

estal mounting hardware. Separate the pedestal

(16) from the power source and retain the shaft key

(25).

Remove the pedestal drain plug (30) and drain the

lubricant from the pedestal. Clean and reinstall the

drain plug.

Remove the nuts (32) and separate the pedestal

from the pump casing (1). Remove the casing gas

ket (12).