Gorman-Rupp Pumps 54J20-B 1410811 and up User Manual

Page 13

OM-01342

50 SERIES

PAGE B - 6

INSTALLATION

tems using two or more belts, make certain that the

belts are a matched set; unmatched sets will cause

accelerated belt wear.

MISALIGNED:

SHAFTS

NOT PARALLEL

MISALIGNED:

SHAFTS

NOT IN LINE

ALIGNED: SHAFTS

PARALLEL AND

SHEAVES IN LINE

Figure 5. Alignment of V‐Belt Driven Pumps

Tighten the belts in accordance with the belt manu

facturer's instructions. If the belts are too loose,

they will slip; if the belts are too tight, there will be

excessive power loss and possible bearing failure.

Select pulleys that will match the proper speed ra

tio; overspeeding the pump may damage both

pump and power source.

Do not operate the pump without the

guard in place over the rotating parts

.

exposed rotating parts can catch cloth

ing, fingers, or tools, causing severe in

jury to personnel.

DRIVE BELT TENSIONING

General Rules of Tensioning

For new drive belts, check the tension after 5, 20

and 50 hours of operation and re‐tension as re

quired (see the following procedure for measuring

belt tension). Thereafter, check and re‐tension if re

quired monthly or at 500 hour intervals, whichever

comes first.

Ideal drive belt tension is the lowest tension at

which the belt will not slip under peak load condi

tions. Do not over‐tension drive belts. Over‐ten

sioning will shorten both drive belt and bearing life.

Under‐tensioning will cause belt slippage. Always

keep belts free from dirt, grease, oil and other for

eign material which may cause slippage.

Tension Measurement

Correct v‐belt tension can be achieved using a v‐

belt tension tester and Table 1 or 2. Use the tables

to find the v‐belt size (cross‐section), the smallest

sheave diameter, the belt type for your application.

The corresponding deflection force required for

new or used belts is shown opposite the RPM

range of the pump.

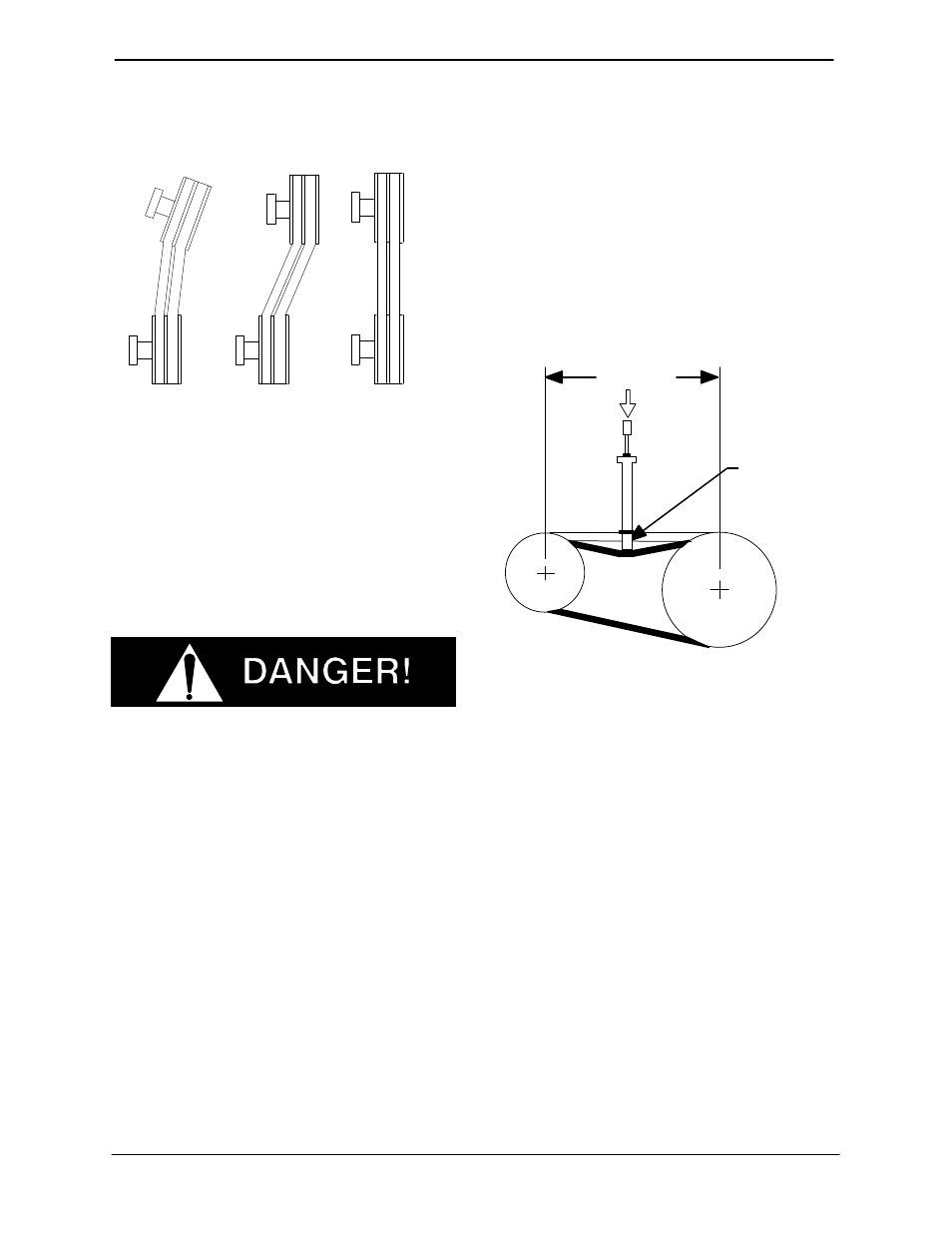

Belt Span

Deflection

Figure 6. Belt Tension Measurement

The ratio of deflection to belt span is 1:64 for both

ASA and metric units. Therefore, a belt with a span

of 64 inches would require a deflection of 1 inch at

the force shown on the Tables for your particular

application.

For example, if the span as measured in Figure 6 is

32 inches (813 mm), the v‐belt cross‐section is C,

the smallest sheave diameter is 8 inches, the pump

speed is 1250 RPM, and the belts are uncogged

Yy‐T type, then 11.5 lbs. of force on the tensioner

should show 1/2‐inch (12,7 mm) of deflection.

A tension tester is available as an option from Gor

man‐Rupp (P/N 29513-001). Other tension test

ers are available from your local belt/sheave dis

tributor, and work on a similar principal.

To use the Gorman‐Rupp tensioner, measure the

belt span as shown in Figure 6. Position the bottom

of the large O‐ring on the span scale of the tension

er at the measured belt span. Set the small O‐ring

on the deflection force scale to zero.