Gorman-Rupp Pumps 54J20-B 1410811 and up User Manual

Page 31

OM-01342

50 SERIES

MAINTENANCE & REPAIR

PAGE E - 9

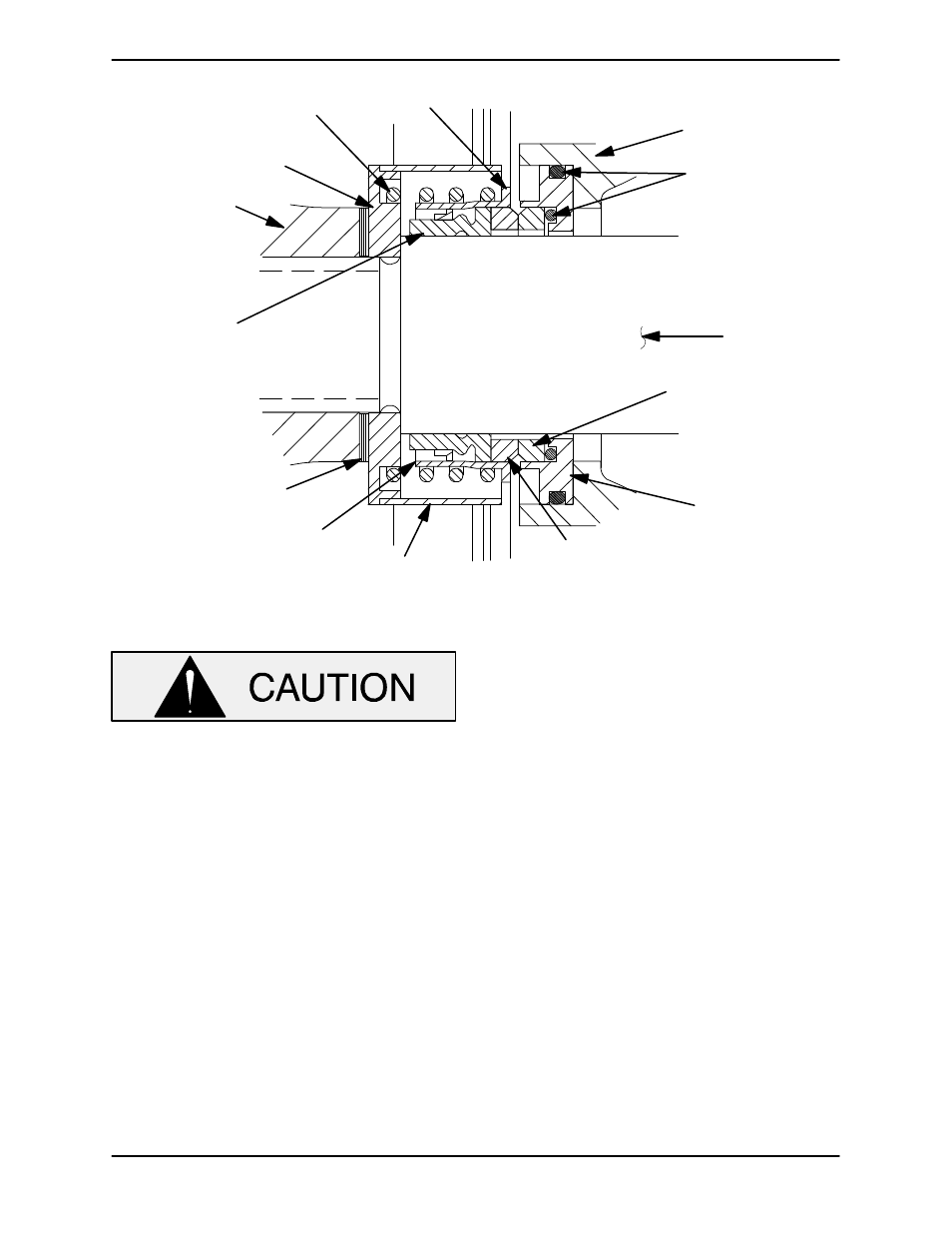

SEAL HOUSING

O‐RINGS

IMPELLER

STATIONARY

STATIONARY

ROTATING

DRIVE BAND

BELLOWS

IMPELLER SHIMS

IMPELLER

SPRING

RETAINER

ELEMENT

ELEMENT

SEAT

SHAFT

SPRING CENTERING

WASHER

SEAL GUARD

Figure 4. 12461C Seal Assembly

This seal is not designed for operation at

temperatures above 160

_

F (71

_

C). Do not

use at higher operating temperatures.

Position the seal housing (7) on a flat surface with

the impeller side facing up. Lubricate the stationary

seat O‐rings with light lubricating oil and subas

semble the stationary element in the stationary

seat. Press this subassembly squarely into the seal

housing bore until fully seated. Be careful not to

damage the seal face. A push tube cut from a

length of plastic pipe would aid in this installation.

The I.D. of the tube should be approximately the

same as the I.D. of the seal spring.

After installation, clean the stationary seal face with

a clean, lint‐free tissue. Wipe lightly in a concentric

pattern to avoid scratching the face.

Replace the seal housing gasket (35). Be sure to

align the lubrication ports in the pedestal with the

holes in the gasket.

Slide the assembled seal housing and stationary

portion of the seal onto the impeller shaft and se

cure the seal housing to the pedestal with the hard

ware (10 and 11). Be careful not to damage the

seal face.

Subassemble the rotating element into the retainer

and bellows and slide this subassembly onto the

shaft until the seal elements contact. Install the

spring and the seal guard assembly.

Lubricate the seal assembly as described in LU

BRICATION after the impeller is installed.

Impeller And Wear Ring Installation

If the wear ring (6) was removed for replacement,

remove the jacking screws, align the mounting

holes, and press the wear ring into the pump cas

ing until fully seated. Apply `Never‐Seez' or equiva

lent compound to the hardware (4 and 5) and se

cure the wear ring to the pump casing.