Gorman-Rupp Pumps 16C2-4045T 1514991 and up User Manual

Page 35

OM-06541

10 SERIES

MAINTENANCE & REPAIR

PAGE E - 15

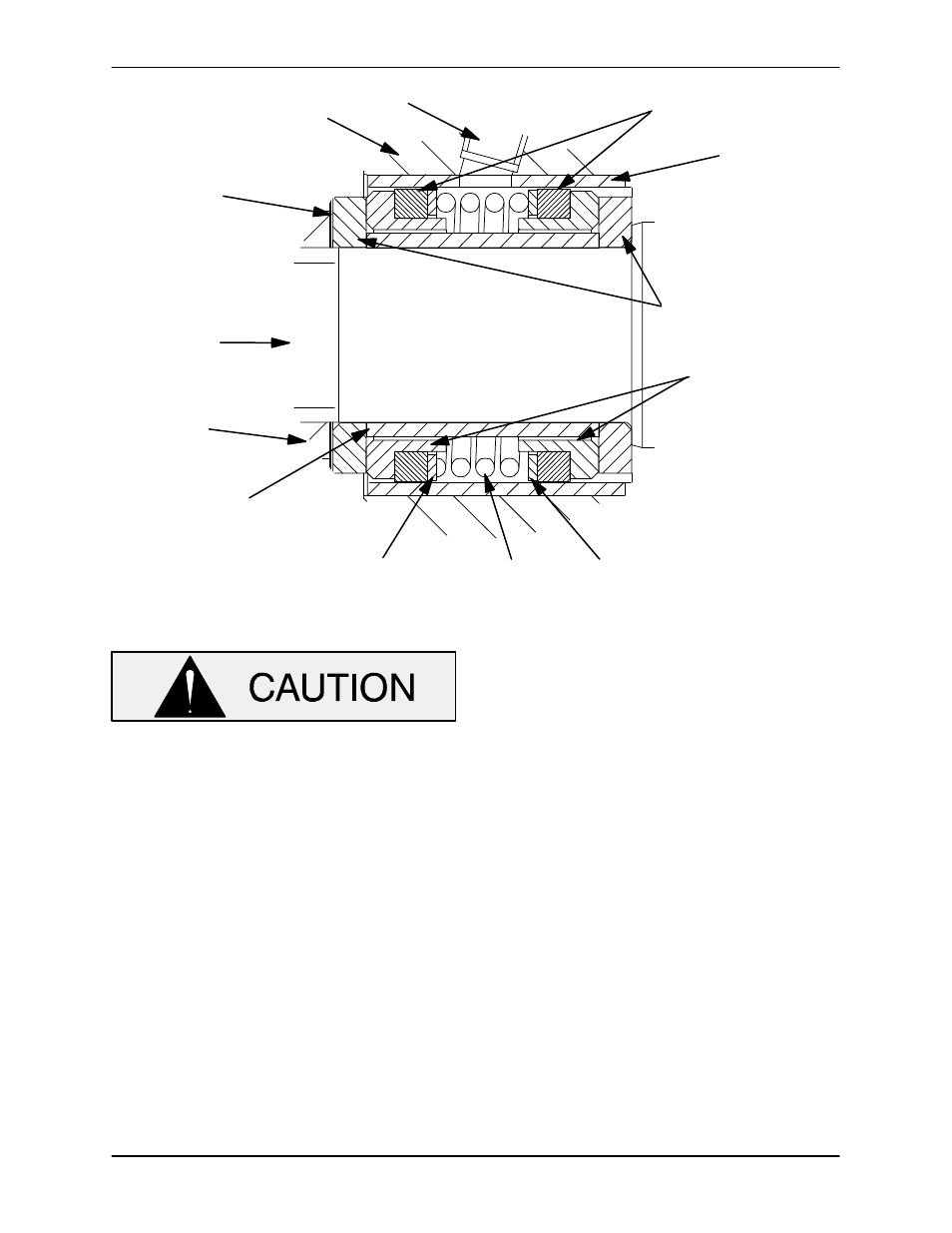

PACKING RINGS

STATIONARY

SEAL SEAT

IMPELLER

SHAFT

SPRING

IMPELLER

ROTATING ELEMENT

STATIONARY WASHER

SEAL PLATE

PIPE NIPPLE

SEAL LINER

STATIONARY WASHER

SHAFT SLEEVE

IMPELLER

ADJ SHIMS

Figure 6. GS1500 Seal Assembly

This seal is not designed for operation at

temperatures above 110

_F (43_C). Do not

use at higher operating temperatures.

Inspect the seal plate (48), seal liner (76), and the

impeller shaft (42) for burrs or sharp corners, and

remove any that exist. Replace the seal liner if wear

or grooves exist which could cause leakage or

damage to the seal packing rings. To replace the

seal liner, position the seal plate on the bed of an

arbor (or hydraulic) press and use a new sleeve to

force the old one out. After the new liner is properly

installed, a 1/4 inch (6,4 mm) diameter hole must

drilled through it to permit the flow of lubricant to

the seal assembly. Be careful to center the drill in

the threaded grease pipe hole and not damage the

threads. Deburr the hole from the inside of the seal

liner after drilling.

Slide the seal plate onto the shaft until fully seated

against the intermediate. Align the threaded seal

lubricant hole with the intermediate opening and

temporarily secure the seal plate to the intermedi

ate with two capscrews and nuts (1/2 UNC X 1‐1/2

inch long, not supplied).

Install the inboard rotating element with the cham

fered side facing the shaft shoulder.

Subassemble the stationary seal seats, packing

rings, stationary washers, and spring onto the

shaft sleeve. Apply a drop of light oil on the preci

sion finished faces of the stationary seats; never

use grease. Slide the entire subassembly into the

lubricated seal liner until it bottoms against the in

board rotating element.

Install the outboard rotating element with the

chamfered side facing the impeller.

Reinstall the automatic grease cup and piping (17,

18, and 19).

Lubricate the seal as indicated in LUBRICATION,

after the impeller has been installed.