Gorman-Rupp Pumps T2A3-B /F,/FM,/WW User Manual

Page 34

OM-05136

T SERIES

MAINTENANCE & REPAIR

PAGE E - 11

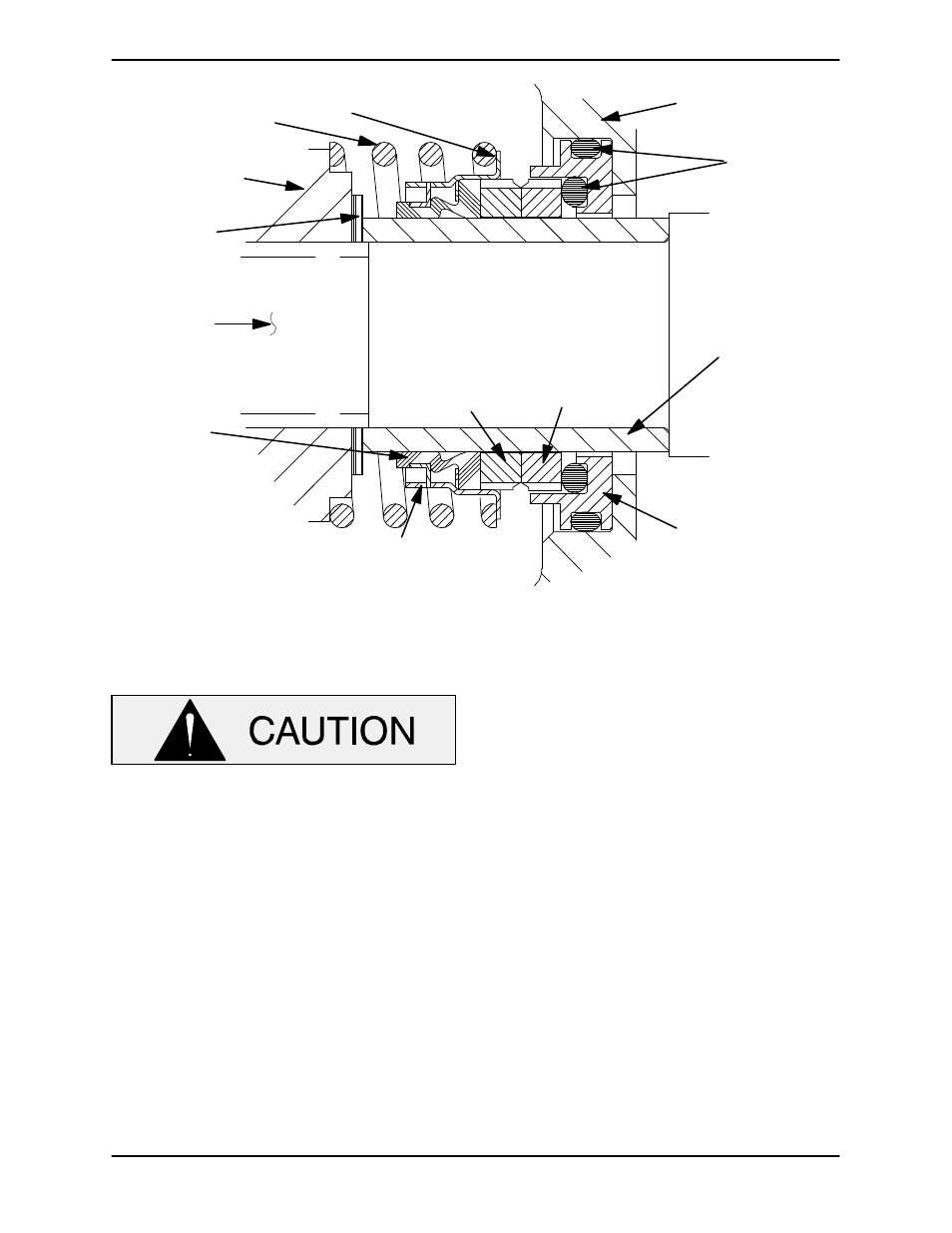

SEAL PLATE

O‐RINGS

IMPELLER

SHAFT

STATIONARY

SEAT

STATIONARY

ELEMENT

ROTATING

ELEMENT

DRIVE BAND

BELLOWS

IMPELLER

SHIMS

IMPELLER

SPRING

RETAINER

INTEGRAL

SHAFT

SLEEVE

Figure 4. 46512-034 Seal Assembly

This seal is not designed for operation at

temperatures above 160

_

F (71

_

C). Do not

use at higher operating temperatures.

Lubricate the stationary seat O‐rings with water or

light oil, and install them in the stationary seat. In

stall the stationary seal element in the stationary

seat. Press this stationary subassembly into the

front of the seal plate (5) until it seats squarely

against the bore shoulder. A push tube made from

a piece of plastic pipe would aid this installation.

The I.D. of the pipe should be slightly larger than

the O.D. of the shaft sleeve.

Install the seal plate gasket (6). Position the seal

plate over the shaft and secure it to the bearing

housing with the hardware (28 and 29). Be careful

not to damage the stationary element on the shaft

threads.

Lubricate the shaft sleeve (4) with a small amount

of light oil and slide the rotating subassembly (con

sisting of rotating element, bellows and retainer),

onto the sleeve until the rotating element is just

flush with the undercut end of the sleeve.

Slide the sleeve and subassembled seal onto the

shaft until the seal faces contact. Continue to push

the sleeve through the seal until the undercut end

seats against the shaft shoulder.

Install the seal spring. Lubricate the seal as indi

cated in LUBRICATION after the impeller is in

stalled.

If necessary to reuse an old seal in an emer

gency, carefully separate the rotating and station

ary seal faces from the bellows retainer and sta

tionary seat.