Gorman-Rupp Pumps T2A3-B /F,/FM,/WW User Manual

Page 30

OM-05136

T SERIES

MAINTENANCE & REPAIR

PAGE E - 7

Suction Check Valve Removal

(Figure 1)

If the check valve assembly (36) is to be serviced,

remove the hardware (3 and 4), and remove the

check valve cover (2). Pull the complete assembly

from the pump casing (1).

NOTE

Further disassembly of the check valve is not re

quired since it must be replaced as a complete unit.

Individual parts are not sold separately.

Rotating Assembly Removal

(Figure 2)

The rotating assembly may be serviced without

disconnecting the suction or discharge piping;

however, the power source must be removed to

provide clearance.

The impeller (1) should be loosened while the rotat

ing assembly is still secured to the pump casing.

Before loosening the impeller, remove the seal cav

ity drain plug (21) and drain the seal lubricant. This

will prevent the oil in the seal cavity from escaping

when the impeller is loosened. Clean and reinstall

the seal cavity drain plug.

Immobilize the impeller by wedging a block wood

between the vanes and the pump casing, and re

move the impeller capscrew and washer (30 and

31).

Install the shaft key (17). Install a lathe dog on the

drive end of the shaft (16) with the “V” notch posi

tioned over the shaft key.

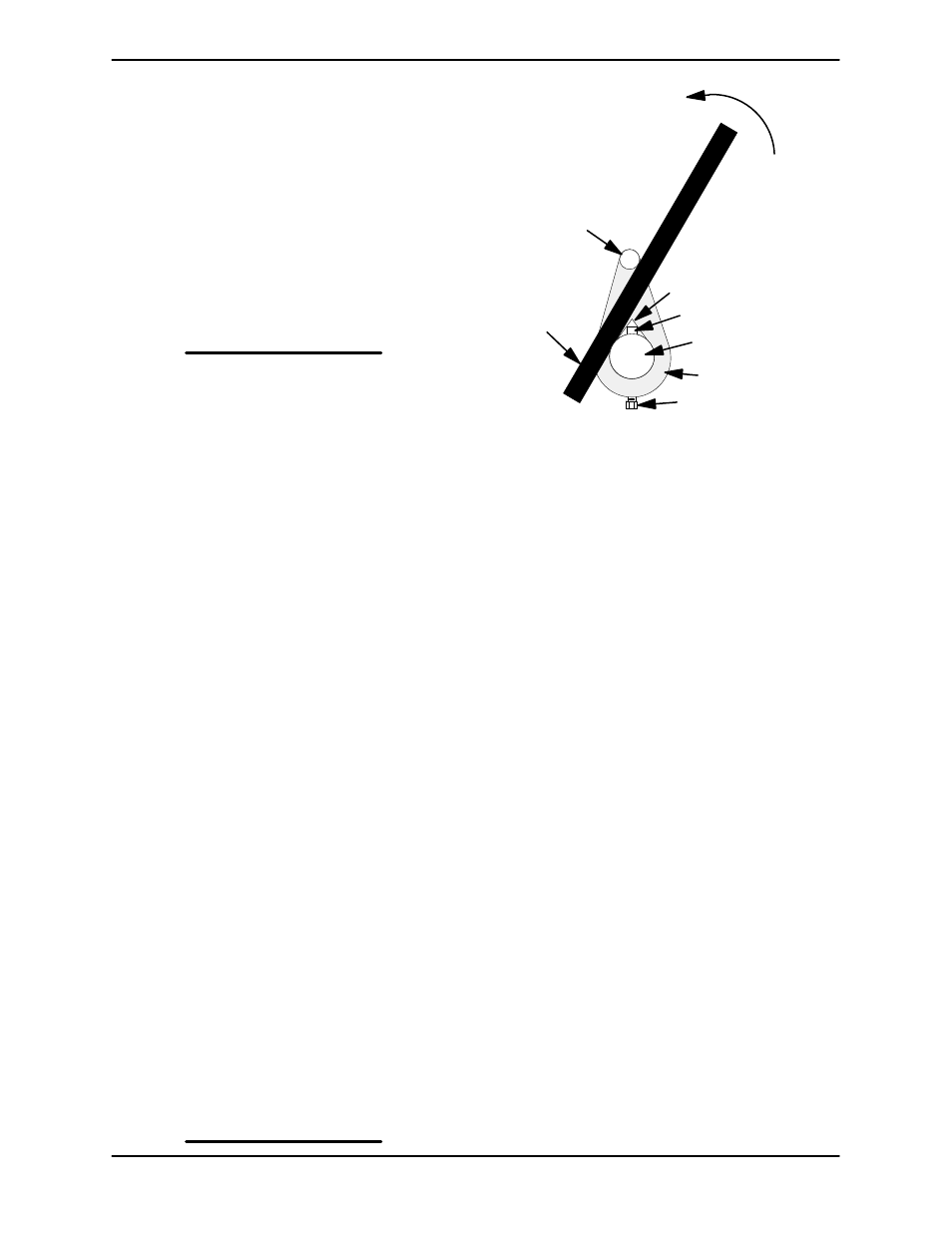

With the impeller rotation still blocked, see Figure 3

and use a long piece of heavy bar stock to pry

against the arm of the lathe dog in a counterclock

wise direction (when facing the drive end of the

shaft). Use caution not to damage the shaft or key

way. When the impeller breaks loose, remove the

lathe dog, key and wood block.

NOTE

Do not remove the impeller until the rotating assem

bly has been removed from the pump casing.

Turn

Counterclockwise

Lathe Dog Arm

“V” Notch

Shaft Key

Impeller Shaft

Lathe Dog

Setscrew

Heavy

Bar Stock

Figure 3. Loosening Impeller

(Figure 1)

Remove the hardware (14 and 15) securing the ro

tating assembly to the pump casing. Install two

3/8‐16 UNC x 2‐1/2 inch long capscrews (not sup

plied) in the tapped holes in the bearing housing.

Use these jacking screws to remove the rotating

assembly from the pump casing. Tie and tag the

rotating assembly shims (16) or measure and re

cord their thickness for ease of reassembly.

Remove the two jacking screws from the bearing

housing. Remove the bearing housing O‐ring (12).

Impeller Removal

(Figure 2)

With the rotating assembly removed from the

pump casing, unscrew the impeller from the shaft.

Use caution when unscrewing the impeller; ten

sion on the shaft seal spring will be released as the

impeller is removed. Inspect the impeller and re

place it if cracked or badly worn.

Remove the impeller adjusting shims (3); tie and

tag the shims, or measure and record their thick

ness for ease of reassembly.

Seal Removal

(Figure 2)

Remove the seal spring.

Slide the shaft sleeve and rotating portion of the

seal off the shaft as a unit. Apply oil to the sleeve