Gorman-Rupp Pumps 86A2-4024H 1535998 and up User Manual

Page 11

OM-06413

80 SERIES

PAGE B - 4

INSTALLATION

Strainers

If a strainer is furnished with the pump, be certain

to use it; any spherical solids which pass through a

strainer furnished with the pump will also pass

through the pump itself.

If a strainer is not furnished with the pump, but is

installed by the pump user, make certain that the

total area of the openings in the strainer is at least

three or four times the cross section of the suction

line, and that the openings will not permit passage

of solids larger than the solids handling capability

of the pump.

This pump is designed to handle up to 1‐15/16 inch

(49,21 mm) diameter spherical solids.

Sealing

Since even a slight leak will affect priming, head,

and capacity, especially when operating with a

high suction lift, all connections in the suction line

should be sealed with pipe dope to ensure an air

tight seal. Follow the sealant manufacturer's rec

ommendations when selecting and applying the

pipe dope. The pipe dope should be compatible

with the liquid being pumped.

Suction Line Positioning

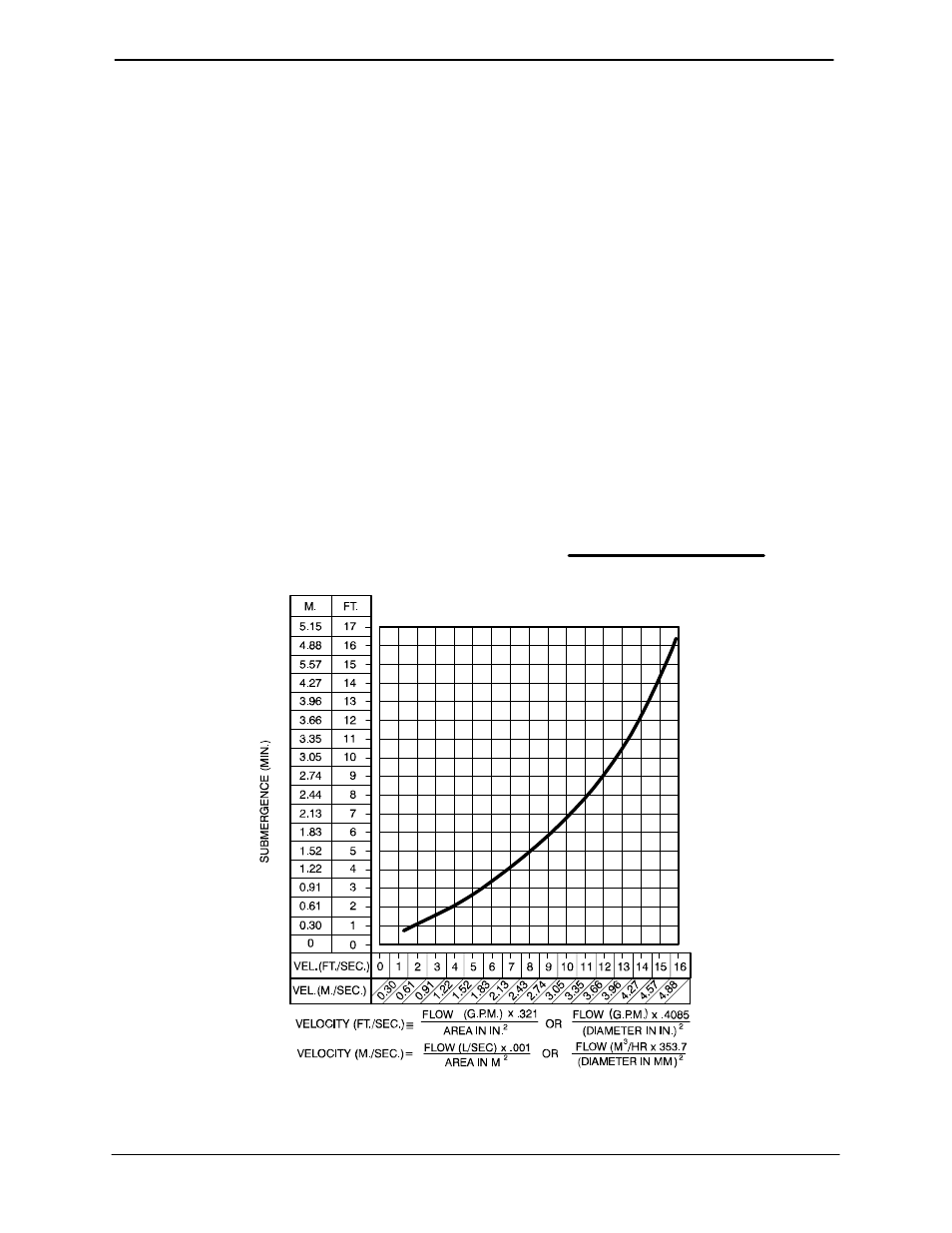

The depth of submergence of the suction line is

critical to efficient pump operation.

Figure 2

shows

recommended minimum submergence vs. veloc

ity.

NOTE

The pipe submergence required may be reduced

by installing a standard pipe increaser fitting at the

end of the suction line. The larger opening size will

reduce the inlet velocity. Calculate the required

submergence using the following formula based

on the increased opening size (area or diameter).

Figure 2. Recommended Minimum Suction Line Submergence vs. Velocity