Gorman-Rupp Pumps 08C1-GA 1026171 and up User Manual

Page 28

0 SERIES

OM−01265

MAINTENANCE & REPAIR

PAGE E − 8

4

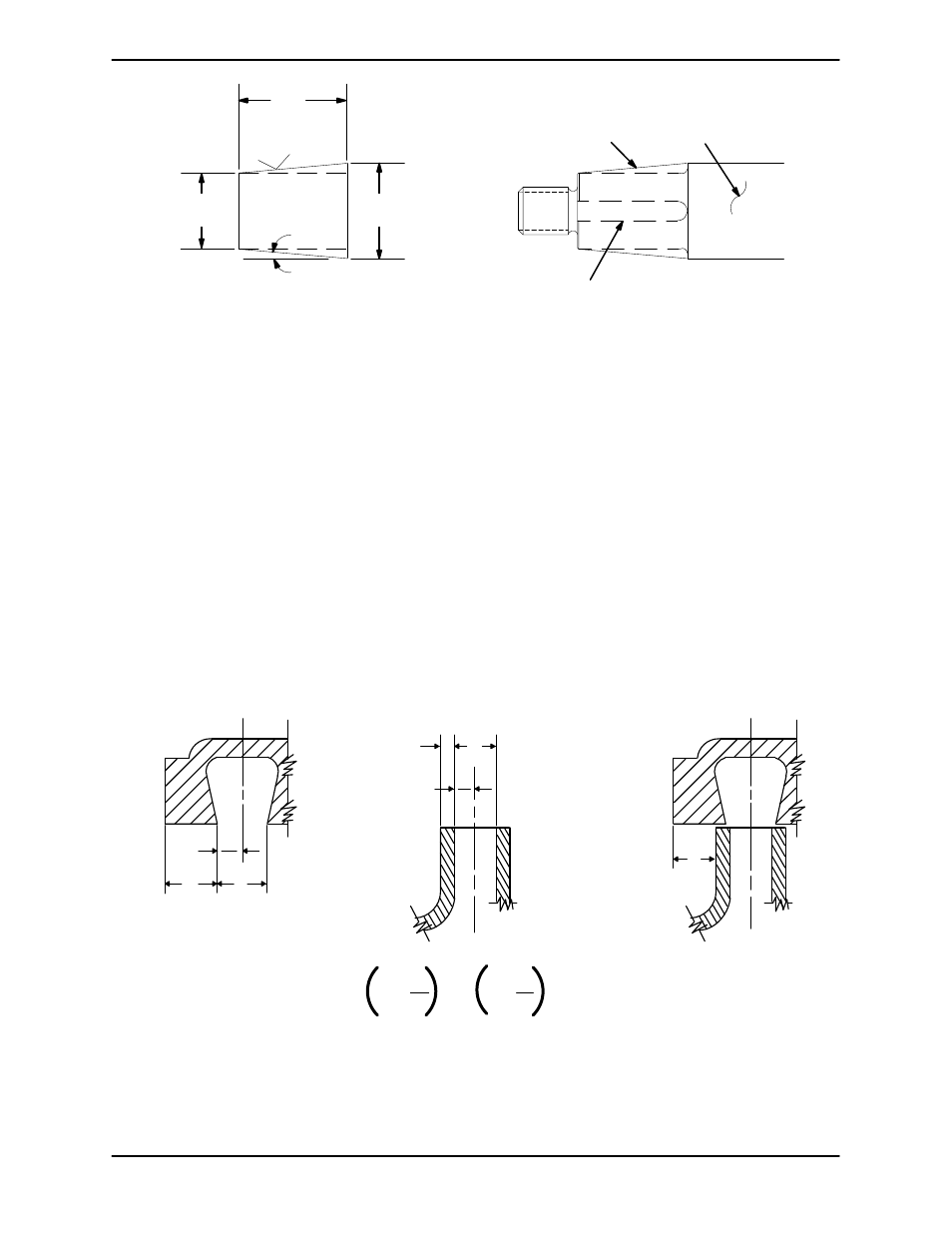

_ TAPER

(APPROX.)

SLEEVE

1.251 D

1.69

FINISH ALL OVER TO

BE 50 RMS OR LESS

ENDS TO BE SQUARE

AND PARALLEL

42,9 mm

31,8 mm

IMPELLER

SHAFT

SEAL

AREA

KEYWAY

1.50 D

38,1 mm

SLEEVE DIMENSIONS

SLEEVE INSTALLED

32

Figure 3. Seal Installation Sleeve

Lubricate the tapered sleeve and position it on the

shaft. Position the rotating portion of the seal (con-

sisting of the retainer, bellows and rotating ele-

ment) on the sleeve, and apply even pressure

against the shoulder of the seal retainer until the ro-

tating subassembly slides onto the shaft and the

seal faces contact. A push tube cut from a piece of

plastic tubing would aid this installation. The I.D. of

the tube should be approximately the same diame-

ter as the I.D. of the seal spring.

Remove the tapered sleeve and install the seal

spring. Make sure that all components of the seal

are seated squarely.

Impeller Installation

(Figures 1 and 4)

Inspect the impeller (2), and replace it if cracked or

badly worn.

For maximum pump efficiency, the impeller must

be centered within the volute scroll. To verify impel-

ler positioning, measure the pump casing and im-

peller as shown in Figure 4. Use these measure-

ments to calculate the required impeller location

(dimension E). Add or remove impeller adjusting

shims (55) to obtain dimension E.

D

B

2

A

B

2

C

D

E

Step 2

Step 1

Step 3

A+

B

2

C+

D

2

E

=

−

Figure 4. Centering Impeller Within Pump Casing

With the correct thickness of impeller adjusting

shims installed, apply ‘Loctite Primer Grade T’, fol-

lowed by ‘Loctite Retaining Compound No. 242’ to

the keyway, impeller key (51) and shaft threads

(use no substitutes).