Design criteria of metering pumps – Pump Solutions Group Neptune Series 500 Specs Municipal User Manual

Page 2

7-01-2001 2

(Note to Specification Writer: Statement regarding replacement valves is very

important. The most frequent maintenance operation performed on any chemical

metering pump is valve cleaning and inspection.)

E.

Materials of construction –Pumps shall be of corrosion resistant

material suitable for the intended service conditions.

III. Spare Parts

A. Provide a routine preventative maintenance kit for each pump

containing a diaphragm, a complete set of o-rings and check valves.

IV. Accessories

A. Calibration Cylinder – Provide a calibration cylinder for mounting in

each pump suction line. Each calibration cylinder shall be sized for a

30 second minimum test, graduated in milliliters and labeled to allow

easy conversion to gallons per hour. Construction shall be clear, PVC

(except for Concentrated Sulfuric Acid, which will be shielded glass)

and shall include a vent connection.

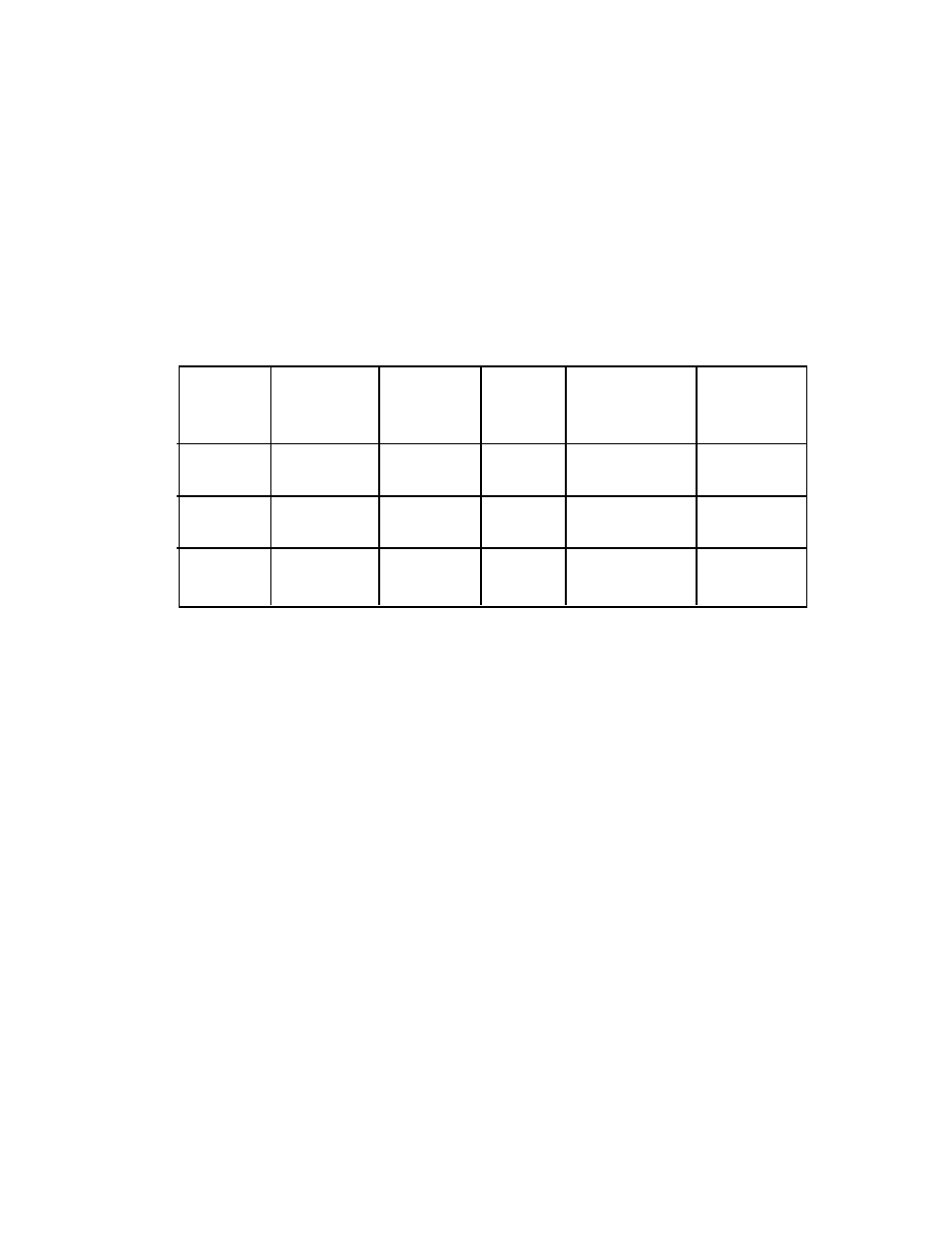

Equipment

Chemical

Feed Range

Design

Type of Drive

Power

No.

Solution

GPH

Pressure

Constant Speed

Available

Min./Max

Variable Speed

AC or DC

Example #1

15%Sodium

5-22 gph

100 psi

Constant Speed

115V-1PH

Hypochlorite

Example #2

Concentrated

2-12 gph

100 psi

DC Variable

115V-1PH

Sulfuric Acid

Speed

Example #3

50%Sodium

3-17 gph

100 psi

AC Variable

460V-3PH

Hydroxide

Speed

Design Criteria of Metering Pumps