Spencer VB055 Vortex Regenerative Blowers User Manual

Page 5

55

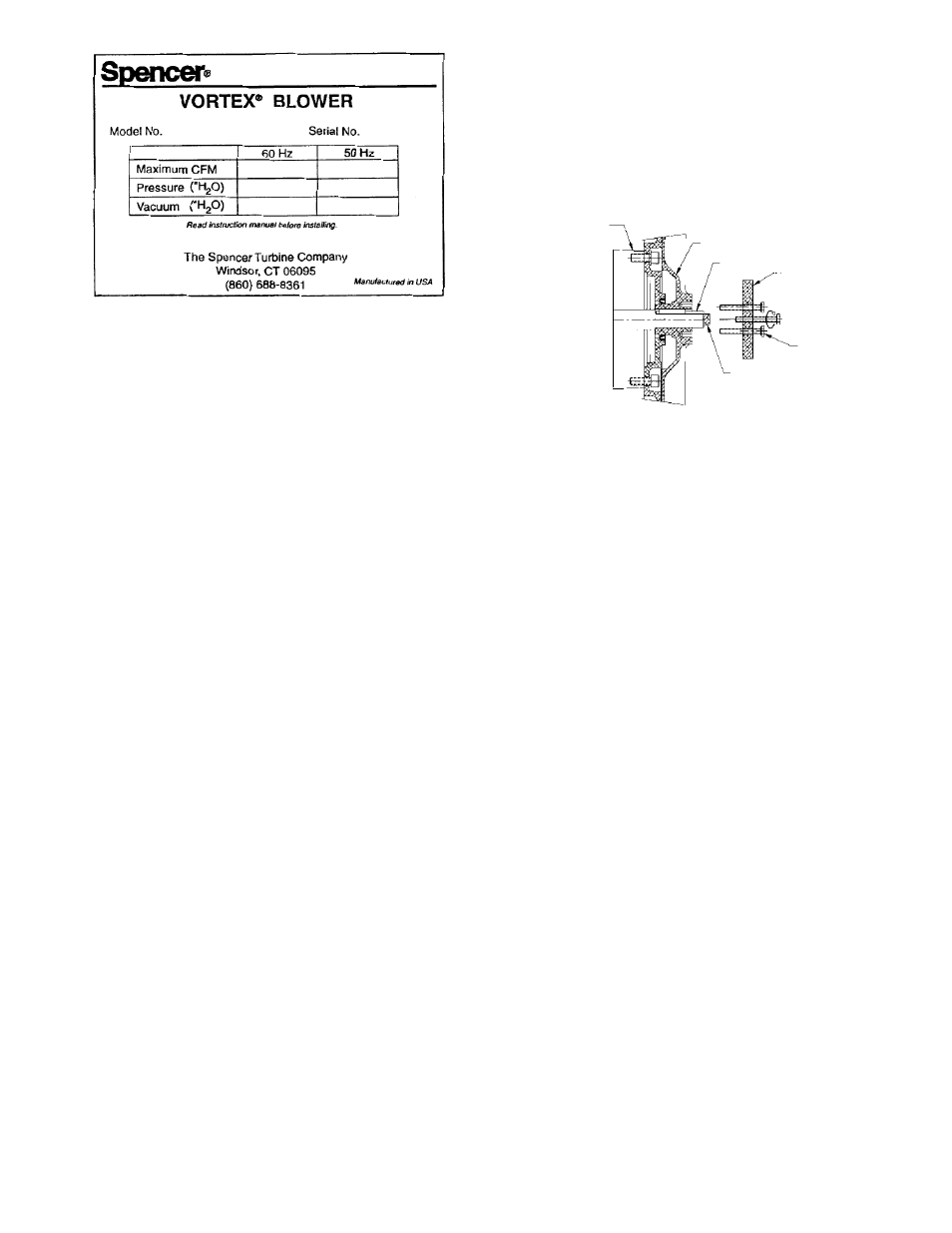

FFiigg.. 44 TTyyppiiccaall NNaam

meeppllaattee

IIIIII.. O

Oppeerraattiioonn

LLiim

miittss ooff O

Oppeerraattiioonn

Operation at flows less than those indicated by the solid

line on the applicable performance curve will cause

overheating of the unit and is to be avoided. TThhrroottttlliinngg

ssuuccttiioonn oorr ddiisscchhaarrggee ppiippiinngg ttoo rreedduuccee aaiirr vvoolluum

mee

iinnccrreeaasseess ddiiffffeerreennttiiaall pprreessssuurree rreessuullttiinngg iinn eelleevvaatteedd

tteem

mppeerraattuurree aanndd iinnccrreeaasseedd ppoowweerr ccoonnssuum

mppttiioonn.. UUssee

ooff pprreessssuurree aanndd// oorr vvaaccuuuum

m rreelliieeff vvaallvvee rreeccoom

mm

meennddeedd..

Maximum pressure and vacuum are indicated on the

nameplate (see Fig. 4). These represent conditions at

which the minimum allowable airflow (CFM) occurs.

Check the operating pressure or vacuum to assure that

the pressure or vacuum remains less than maximum.

For continuous operation at low air volume (on the

dotted portion of the performance curve), provide a

bypass in the piping and operate at a lower pressure

than maximum operating pressure. See Performance

Curves, Section V.

CCaauuttiioonn:: LLooww ffllooww ccoonnddiittiioonnss m

maayy pprroodduuccee hheeaatt lleevveellss

wwhhiicchh m

maayy ccaauussee bbuurrnnss.. DDoo nnoott ttoouucchh tthhee bblloowweerr iinn

ooppeerraattiioonn..

TTeem

mppeerraattuurree RRiissee

A NEMA Class F insulation system is used in the motor.

Maximum allowable winding temperature is 265˚F. If a

thermal protector or thermal relay activates because the

temperature rise of the motor is higher than usual, inves-

tigate and correct the problem. Explosion-proof motors

use a NEMA Class B insulation. Typical causes of motor

overheating are given in Section VI, Troubleshooting

Guide.

IIVV.. DDiissaasssseem

mbbllyy aanndd

RReeaasssseem

mbbllyy

AA.. G

Geenneerraall

1. Precautions should be taken when disassembling

or reassembling the blower. See Warranty Terms.

2. Keep all parts clean.

3. Do not overtighten bolts and screws.

FFiigg.. 55 IIm

mppeelllleerr PPuulllleerr

BB.. DDiissaasssseem

mbbllyy PPrroocceedduurree ((RReeaasssseem

mbbllyy iiss ppeerrffoorrm

meedd

iinn rreevveerrssee oorrddeerr))

CCaauuttiioonn:: SShhiim

mss aarree uusseedd ttoo aaddjjuusstt tthhee ggaapp bbeettwweeeenn

tthhee iim

mppeelllleerr aanndd ccaassiinngg.. W

Whheenn ddiissaasssseem

mbblliinngg,,

ttaakkee ccaarree ttoo nnoottee tthhee qquuaannttiittyy ooff sshhiim

mss aanndd tthheeiirr

tthhiicckknneessss.. TThhee sshhiim

m ssttaacckk rreeppllaacceem

meenntt m

muusstt bbee

tthhee ccoorrrreecctt tthhiicckknneessss ttoo aassssuurree pprrooppeerr cclleeaarraannccee

aanndd ttoo aavvooiidd ddeeggrraaddaattiioonn ooff ppeerrffoorrm

maannccee..

1. Remove impeller cover; remove screws, pull cover

away from case.

2. Unfasten lock washer; remove nut and washer.

3. Remove impeller from shaft by one of the following

methods:

a. manually pull the impeller outward, OR

b. screw two bolts into tapped holes and pull on

the bolts, OR (if the fit is tight)

c. use a puller assembly (not furnished) as shown in

Fig. 5.

4. Remove motor shaft key.

5. Remove case from motor; if necessary remove

screws holding case to base and motor to case.

6. Remove shims from motor shaft if necessary; do

not discard them. See Note above.

C

Caauuttiioonn:: M

Moottoorrss aarree hheeaavvyy.. LLiifftt m

moottoorr oonn m

mooddeellss

llaarrggeerr tthhaann VVBB000022 bbyy tthhee eeyyeebboolltt oonn tthhee m

moottoorr w

wiitthh

aann aaiidd ffrroom

m aa lliiffttiinngg ddeevviiccee..

CC.. RReeaasssseem

mbbllyy G

Guuiiddaannccee

1. The gap between the impeller and case is essential for

proper performance of the unit. The shims between

the shaft collar and impeller hub establish the spacing

of this gap. In reassembly, before installing the

impeller cover, check the gap between the impeller

and case to assure that the measurement conforms to

the gap specification on the assembly drawing (on the

following pages) for your unit.

TThhee SSppeenncceerr TTuurrbbiinnee CCoom

mppaannyy

◆

600 Day Hill Road, Windsor, CT 06095

◆

TEL 800-232-4321

◆

860-688-8361

◆

www.spencerturbine.com

YYeeaarr ooff PPrroodduuccttiioonn

THREADED

PLATE

SHIM BLOCK

MOTOR

“C” FACE

IMPELLER

HUB

SHAFT

BOLT