Warning – John Wood Commercial - AJWSC User Manual

Page 20

– 20 –

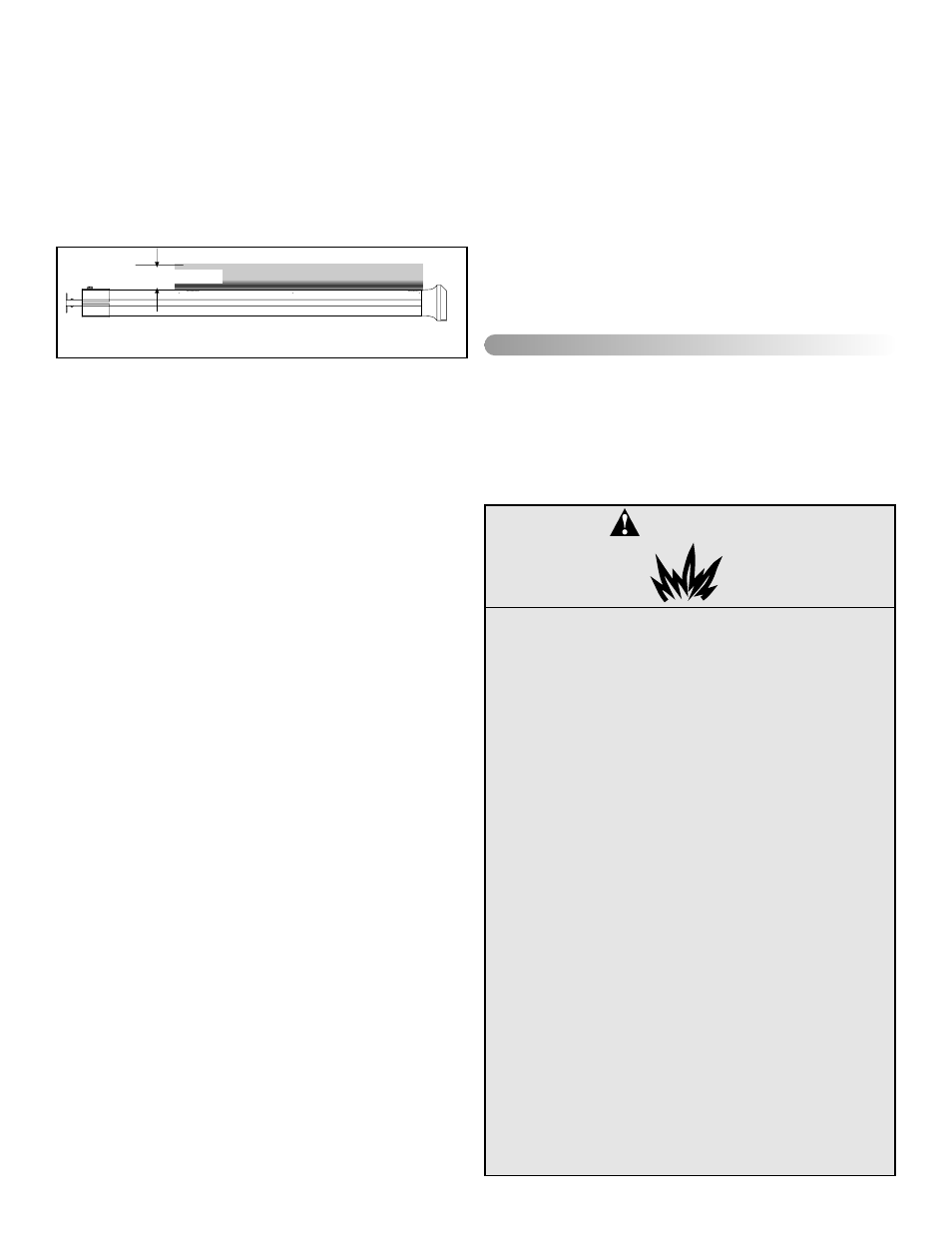

Burner Flames

Inspect the burner flames through the viewport and com-

pare them to the drawings in Figure 15. A properly operat-

ing burner should produce a soft blue flame and be about

50mm (2 in.) to 64mm (2 -1/2 in.) in height. Blue tips with

yellow inner cones are satisfactory. The tips of the flame

may have a slight yellow tint. The flame should not be all

yellow or have a sharp blue-orange colour. Contaminated

air may cause an orange coloured flame. Contact a qualified

service technician if the flame is not satisfactory.

Stacking

Stacking occurs when a series of short draws of hot water

are taken from the water heater tank. This causes increased

cycling of the burner and can result in increased water tem-

peratures at the hot water outlet. A tempering valve should

be installed in the hot water supply line to reduce the risk of

scald injury.

Emergency Shut Down

Important: If overheating occurs or the gas supply fails to

shut off, close the manual gas supply shut-off valve and turn

the gas valve knob to the “OFF” position. Turn off the elec-

trical supply to the unit and close the cold water supply

valve. Do not operate the water heater again until it has

been thoroughly checked by a qualified service technician.

Operational Conditions

Condensation

Moisture from the products of combustion condenses on the

tank surface and the outside jacket of the water heater and

forms drops of water which may fall onto the burner or other

hot surfaces. This will produce a “sizzling” or “frying” noise.

This condensation is normal and should not be con-

fused with a leaking tank. Condensation may increase or

decrease at different times of the year.

High efficient energy saver water heaters will produce larg-

er amounts of condensation on initial start up or when a

large amount of hot water is being used. Do not confuse

this with a “tank leak”. Once the water reaches a temper-

ature of 49°C (120°F) and the tank warms up (usually 1-2

hours), the condensation will stop.

Important: It is always recommended that a suitable drain

pan be installed under the water heater to protect the area

from water damage resulting from normal condensation pro-

duction, a leaking tank or piping connections. Under no cir-

cumstances is the manufacturer to be held responsible for

any water damage in connection with this water heater.

Water Heater Sounds

During the normal operation of the water heater sounds or

noises may be heard. These noises are common and may

result from the following:

1. Normal expansion and contraction of metal parts during

periods of heat-up and cool-down.

2. Condensation causes sizzling and popping within the

burner area and should be considered normal.

3. Sediment buildup in the tank bottom will create varying

amounts of noise and may cause premature tank fail-

ure. Drain and flush the tank as directed under

“Draining and Flushing”.

Smoke/Odour

The water heater may give off a small amount of smoke and

odour during the initial start-up of the unit. This is due to the

burning off of oil from metal parts of a new unit and will dis-

appear after a few minutes of operation.

High Humidity or Dripping Water

Over time, dripping water or high ambient humidity can cre-

ate unwanted electrical paths on the circuit board, causing

the integrated control to fail. Never install an appliance

where water can drip on the controls. In addition, high ambi-

ent humidity can cause the gas valve to corrode and finally

fail. Where the appliance may be installed in a humid

2 - 2 1/2”

Figure 15 Pilot/Burner Flame

50 - 64mm (2 - 2 1/2 in.)

VI) INTEGRATED CONTROL

WARNING

Fire or Explosion Hazard

Can cause severe injury, death or

property damage.

1. The integrated control can malfunction if

it gets wet, leading to accumulation of

explosive gas.

. Never install where water can flood, drip

or condense on the integrated control.

. Never try to use an integrated control

that has been wet - replace it.

2. Liquefied petroleum (LP) gas is heavier

than air and will not vent upward natural-

ly.

. Do not light pilot or operate electric

switches, lights, or appliances until you

are sure the appliance area is free of

gas.

3. If a new gas valve is to be installed, turn

off gas supply before starting installation.

Conduct Gas Leak Test according to gas

valve manufacturer’s instructions after

the gas vavle is installed.

4. If the integrated control must be mounted

near moisture or water, provide suitable

waterproof enclosure.