Water supply piping installation – John Wood Commercial - AJWSC User Manual

Page 12

WATER SUPPLY

Piping Installation

Piping, fittings, and valves should be installed according to

the installation drawing (Figure 7). If the indoor installation

area is subject to freezing temperatures, the water piping

must be protected by insulation. Water supply pressure

should not exceed 80% of the working pressure of the water

heater. The working pressure is stated on the water heater’s

data plate. If this occurs, a pressure reducing valve with a

bypass should be installed in the cold water inlet line to the

entire system. This should be placed on the supply to the

entire structure in order to maintain equal hot and cold water

pressures.

Note: Water supplied to the unit that exceeds 12 grains

(205 mg/l) total hardness may reduce the life and perform-

ance of the water heater. Depending on the degree of hard-

ness, it is recommended that either a water pre-treatment

system or a water softener be installed and properly main-

tained.

Important: Heat cannot be applied to the water fittings on

the water heater as they may contain nonmetallic parts. If

solder connections are used, solder the pipe to the adapter

before attaching the adapter to the hot and cold water fit-

tings.

1. The water heater may have three water piping connec-

tion points. The top and front are 1-1/2” NPT and the

connections on the back of some heaters are 2” NPT.

When using front or back connections a combination

nipple inlet tube is required (top entry uses a dip tube).

Any one of the options listed in Table 5 may be used.

For availability contact 1-888-479-8324.

Note: Inlet and outlet piping connections cannot be mixed.

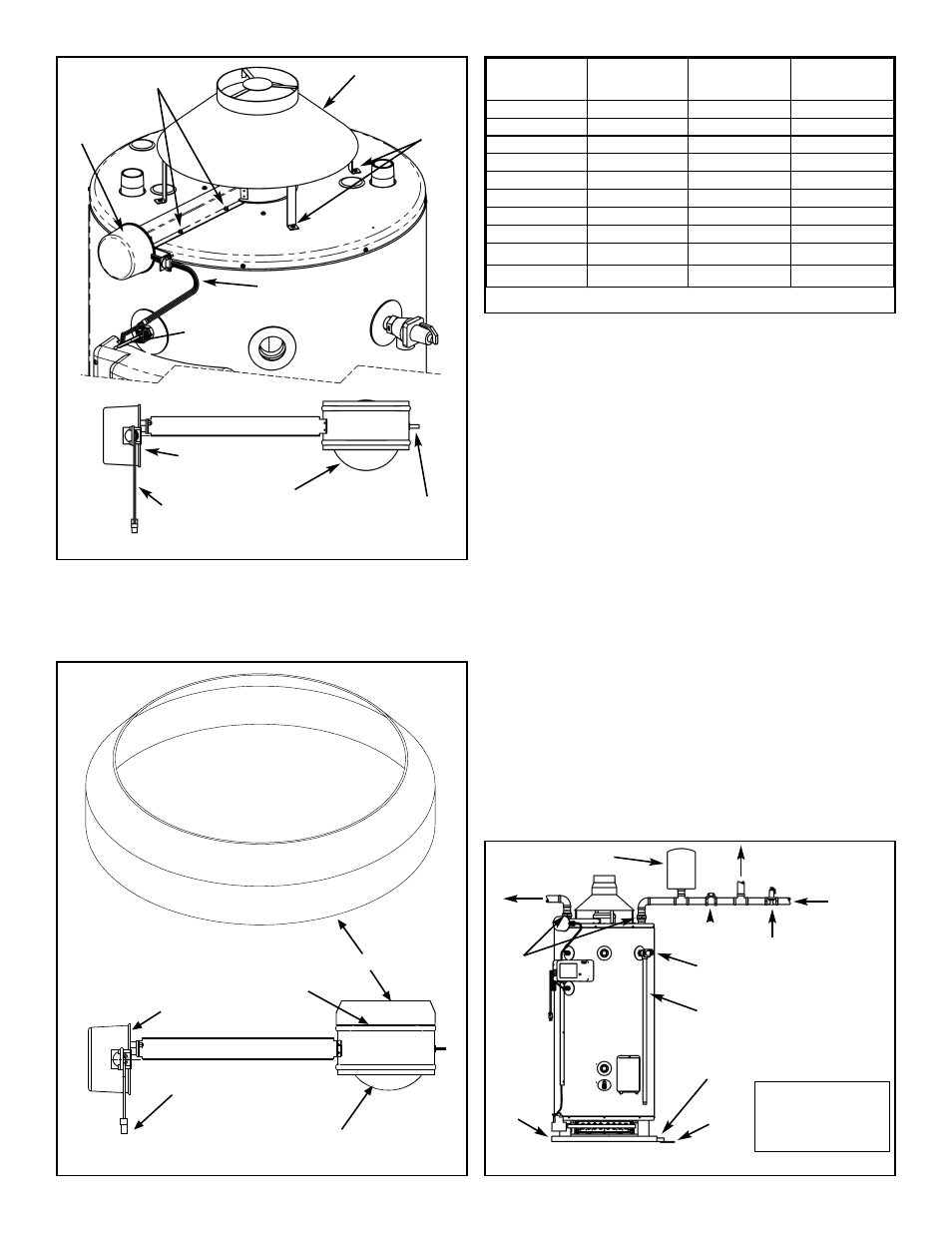

Damper in OPEN position

Damper wiring harness

Damper motor

Flue outlet reducer

High

temperature

silicon sealant

Figure 6 Flue Outlet Reducer

Water Heater

Model Base #

Dip Tube

Inlet Tube

(Optional Front)

Inlet Tube

(Optional Back)

75-125

60238

60239

60239

80-199

60053

60057

60057

80-250

60053

60057

60057

100-199

71325

75085

75086

100-270

71325

75085

60023

75-300

60053

60057

60057

75-360

N/A

60194

60195

75-399

N/A

60194

60195

75-300NO

x

N/A

60194

60195

75-350NO

x

N/A

60194

60195

Table 5

Dip Tube Usage

Figure 7 Water Piping Installation

Massachusetts:

Install a vacuum relief

in cold water line per

section 19MGL 142

Drain line 19mm

(3/4 in.) ID min.

Temperature and

Pressure Relief Valve

Pressure Reducing

Valve with Bypass

Cold Water

Supply to Fixtures

Main Water

Supply

In a closed system use a

Thermal Expansion Tank

Cold Water

Inlet Valve

Hot Water

Outlet

Unions

Floor Drain

Discharge line

152mm (6 in.)

max. above

drain

Metal drain

pan 45mm

(1-3/4 in.)

depth max.

Figure 5 Flue Damper Assembly

– 12 –

Bracket screws

Damper

motor

Drafthood

Drafthood

screws

Damper wiring

harness

Damper wiring

harness

Damper

motor

Damper in

OPEN position

Damper position

indicator

ECO wiring

harness