Warning, Venting, Drafthood/damper installation – John Wood Commercial - AJWSC User Manual

Page 11: Flue outlet reducer

Venting

It is the responsibility of the installing contractor to provide a

vent adequate in capacity and in good usable condition.

Btu/hr capacity limitations are governed by the style and

height of the vent/chimney. Vent piping must be installed in

accordance with all local and provincial or state codes or, in

the absence of such, the latest edition of “Natural Gas and

Propane Installation Code” CAN/CSA-B149.1 (Canada),

or “National Fuel Gas Code” ANSI Z223.1 (NFPA 54)

(U.S.A.).

U.L. recognized fuel gas and carbon monoxide (CO) detec-

tors are recommended in all applications and should be

installed using the manufacturer’s instructions and local

codes, rules, or regulations.

Important: Check to make sure the vent pipe is not blocked

in any way.

• Venting should be as direct as possible with a minimum

number of pipe fittings.

• Exhaust gas vents must be installed with U.L. listed type

B vent pipe according to the vent manufacturer’s instruc-

tions and the terms of its listing.

• Single wall vent connectors must have 152mm (6 in.) of

clearance from unprotected combustible surfaces.

• If sidewall venting is necessary, a power vent kit is

required. For availability contact 1-888-479-8324.

• Vents that run through unconditioned spaces where

below freezing temperatures are expected should be

properly insulated to prevent freezing.

• Existing vent systems must be inspected for obstructions,

corrosion and proper installation.

• Vents must be connected to the water heater’s drafthood

by a certified vent connector or by directly originating at

the drafthood opening.

• Some models are shipped with a vent reducer. The vent

reducer can be installed directly to the drafthood if the

existing vent system is adequately sized to support the

exhaust gases.

• Vertical gas vents must terminate with a listed cap or

other roof assembly and be installed according to their

manufacturer’s instructions.

• Horizontal vent connections must have an upward slope

of at least 21mm per metre (1/4 in per foot).

• Gas vents must be supported to prevent damage, joint

separation, and maintain clearances to combustible

materials.

• Vent connection joints should be fastened by sheet metal

screws or by other approved methods.

• Vent and vent connectors should have adequate support

to keep weight off the drafthood.

All pipe, fittings, and procedures must conform to American

National Standard Institute and American Society for Testing

and Materials (ANSI/ASTM) standards in the United States.

Important: If you lack the necessary skills required to prop-

erly install this venting system, you should not proceed, but

get help from a qualified service technician.

Drafthood/Damper Installation

Install the supplied drafthood and damper on the flue outlet

collar. Use only the supplied drafthood and damper, DO

NOT use any substitute or alter the components in any way.

Place the damper on the water heater (see Figure 5). Align

the four pilot holes on top of the water heater with the 4 cor-

responding holes on the damper bracket and secure with

the supplied screws. Next, align the drafthood legs with the

4 corresponding pilot holes on top of the water heater and

attach securely with the supplied screws. Locate the wiring

from the ECO, and attach it to the wiring harness on the

damper (see Figure 5). Once damper is installed, ensure

that the damper position indicator is visible (See Figure 5).

Flue Outlet Reducer

Some units are shipped with a flue outlet reducer (See

Figure 6). Use only the flue outlet reducer supplied with this

unit. The flue outlet reducer should be connected to the top

of the flue damper and sealed by high temperature silicon.

The vent piping must be installed in accordance with all

local and provincial or state codes or, in the absence of

such, the latest edition of “Natural Gas and Propane

Installation Code” CAN/CSA-B149.1 (Canada), or

“National Fuel Gas Code” ANSI Z223.1 (NFPA 54)

(U.S.A.).

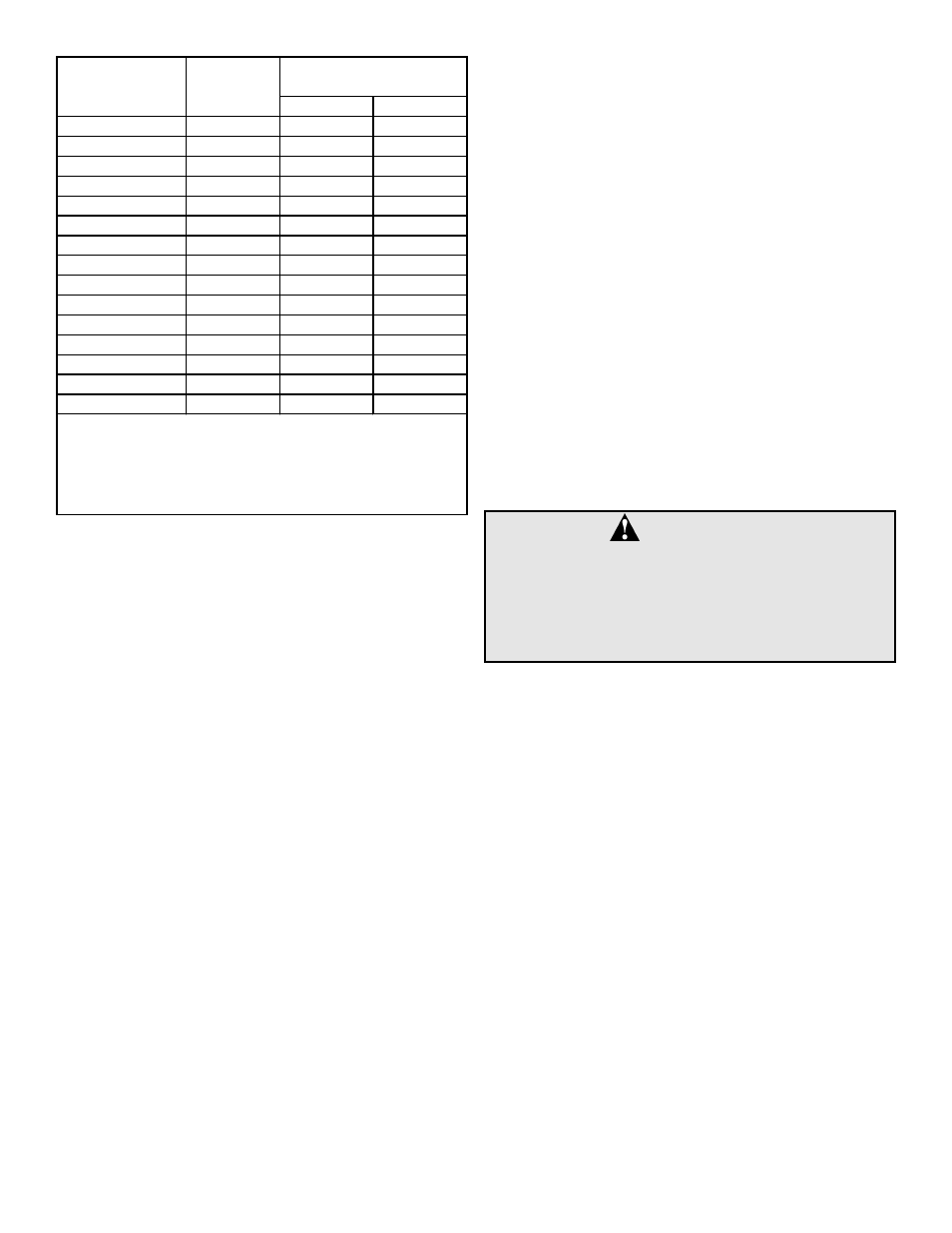

A

1

B

2

BTU/h (kW)

mm2 (in2)

mm (in)

mm (in)

75,000 (23)

7,000 (11)

100 (4)

125 (5)

100,000 (30)

9,000 (14)

100 (4)

125 (5)

125,000 (37)

12,000 (18)

125 (5)

150 (6)

150,000 (45)

14,000 (22)

125 (5)

150 (6)

175,000 (53)

16,000 (25)

150 (6)

175 (7)

200,000 (60)

19,000 (29)

150 (6)

175 (7)

225,000 (68)

21,000 (32)

150 (6)

175 (7)

250,000 (75)

23,000 (36)

175 (7)

200 (8)

275,000 (83)

26,000 (40)

175 (7)

200 (8)

300,000 (90)

28,000 (43)

175 (7)

200 (8)

325,000 (98)

30,000 (47)

200 (8)

225 (9)

350,000 (105)

32,000 (50)

200 (8)

225 (9)

375,000 (113)

35,000 (54)

200 (8)

225 (9)

400,000 (120)

37,000 (58)

225 (9)

250 (10)

Combined input of

all appliances in

confined space

Required

free area of

duct

Acceptable equivalent duct

diameter

Table 4

Notes:

1.

Maximum length of ducts in column A is 6.1 equivalent metres (20

ft).

2.

Maximum length of ducts in column B is 15.2 equivalent metres

(50 ft).

WARNING

Do not operate heater with damper in closed

position, it must be in the open position dur-

ing water heater operation. Do not negate the

action of any existing safety or operational

controls.

– 11 –