Vii) combo heating, System requirements, Installation – John Wood Power Vent (Non-ENERGY STAR qualified models) User Manual

Page 31

– 31 –

VII) COMBO HEATING

This section serves as a guide for the installation and use of

"Combo" heating systems utilizing a domestic water heater

that has been specifically approved for such use. It is writ-

ten for those knowledgeable in the required trades and pro-

fessionals involved in the design and installation of Combo

Heating Systems.

It is the responsibility of the installer/designer to follow

all applicable codes to ensure the effectiveness and

safety of the installation.

System Requirements

The following requirements must be met for the installation

of Combo Heating Systems:

1.

All components used for the distribution of water in the

heating loop must be suitable for potable water. These

include all piping, fittings, solder and fluxes, pumps for

circulation of water, valves, etc.

2.

The water heater must not be connected to a hydronic

heating system that has been used previously.

3.

No boiler treatment chemicals of any kind shall be intro-

duced into the system.

4.

The Combo System components must be selected and

sized to meet and maintain the total calculated

demands for both domestic service hot water and space

heating requirement. The sizing and installation must be

performed in accordance with good engineering prac-

tice such as "ASHRAE Handbooks", HRAI,

"Hydronics Institute Manuals", CSA B149.1, NFPA

54, ANSI Z223.1, CSA F280, National/Provincial

Building Codes, CSA C22.1, ANSI/NFPA 70, CSA

B51 and/or codes having jurisdiction.

5.

The air handler (fan coil) and/or the circulating pump in

a baseboard hydronic loop will require a dedicated

120V circuit. This must be provided and identified for

this purpose.

6.

All piping between the water heater and the air handler

or hydronic baseboard loop must be adequately insulat-

ed to reduce heat loss.

7.

If the local jurisdiction requires a back-flow preventer in

the cold water line, an expansion tank of adequate size

must be installed.

8.

"Combo" Heating Systems require higher water temper-

atures than other applications. When the system is

used to supply water for Combo Heating applications, a

means, such as mixing valve, must be installed to tem-

per the water in order to reduce scald hazard potential

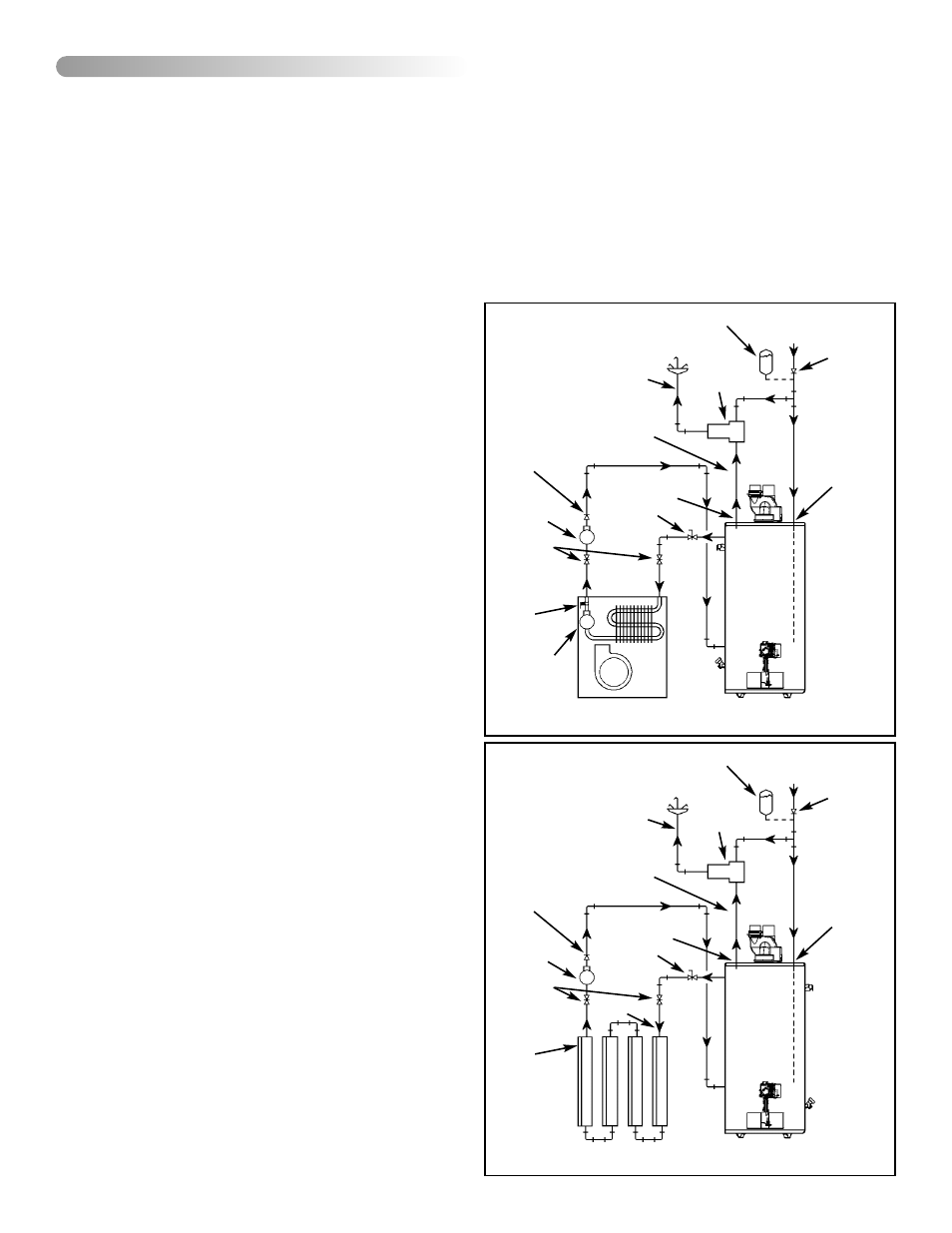

(see Figures 29 & 30).

Installation

The heating mode may be one of the following options:

A. A fan coil/air handler (Figure 29).

B. A hydronic baseboard (finned tube) loop/In floor heating

(Figure 30).

The following is a list of requirements for the installation of

the heating loop to the water heater.

1.

Install shut-off valves and unions so that the water

heater can be isolated from the heating module should

servicing of the water heater become necessary.

2.

Install a drain valve at the lowest point of the heating

loop so that water can be drained from the heating mod-

ule without affecting the water heater.

3.

If the air handler does not have a venting means at the

highest point of the piping arrangement, install an air

bleed at the highest point of the plumbing arrangement.

WATER

HEATER

8in TO 12in

MAX.

H O T

OUTLET

EXPANSION TANK

(OPTIONAL)

MIXING

VALVE

COLD

INLET

CHECK VALVE

(IF USED

REQUIRES

EXPANSION

TANK)

COLD

SUPPLY

HOSE BIB

(OPTIONAL)

FLOW

CONTROL

SUPPLY

RETURN

CHECK

VALVE

EXTERNAL

CIRCULATOR

AIR HANDLER

HOT WATER

TO HOUSE

FIXTURE

C

H

M

I N T E R N A L

CIRCULATOR

DRAIN/PURGE

VALVE

Figure 29 Combo Heating - Air Handler

WATER

HEATER

8in TO 12in

MAX.

H O T

OUTLET

EXPANSION TANK

(OPTIONAL)

MIXING

VALVE

COLD

INLET

CHECK VALVE

(IF USED

REQUIRES

EXPANSION

TANK)

COLD

SUPPLY

HOSE BIB

(OPTIONAL)

FLOW

CONTROL

SUPPLY

RETURN

CHECK

VALVE

EXTERNAL

CIRCULATOR

HOT WATER

TO HOUSE

FIXTURE

C

H

M

HYDRONIC

BASEBOARDS

(SERIES CON-

NECTED

SHOWN)

Figure 30 Combo Heating - Baseboard