Capscrew torque values, Dealer servicing, Capscrew torque values dealer servicing – Bell & Gossett P81568D Series 1535 User Manual

Page 22

The rotating seal assembly includes these parts:

• Seal ring

• Rubber collar

• Brass collar

• Compression ring

4. Push the entire rotating seal assembly onto the shaft as one unit.

Do not attempt to assemble the seal by placing the components on the shaft

individually. Align the notches in the collar with the recesses found on each side of the

carbon ring.

5. Press the seal housing tightly against the upper end of the rubber collar.

Use a screwdriver and press at several points along the periphery in order to provide a

tight and even fit. Do not tap on the seal because you can break the ceramic or carbon

insert.

6. Place the seal spring on the shaft and then the spring retainer.

7. Place the impeller and lockwasher on the shaft.

8. Thread the impeller nut onto the shaft and tighten according to these values:

• 3/8 in. nut to 8 – 12 ft. lbs. (11 – 16 Nm)

• 7/16 in. nut to 17 – 22 ft. lbs (23 – 30 Nm)

Do not overtighten.

9. Clean the pump body of excess debris.

10. Place a new gasket in the recess of the pump body.

11. Replace the motor assembly by inserting the impeller in the pump body and evenly

tighten the eight capscrews.

Tighten the 3/8 in. capscrews to 10 – 14 ft. lbs (14 – 19 Nm).

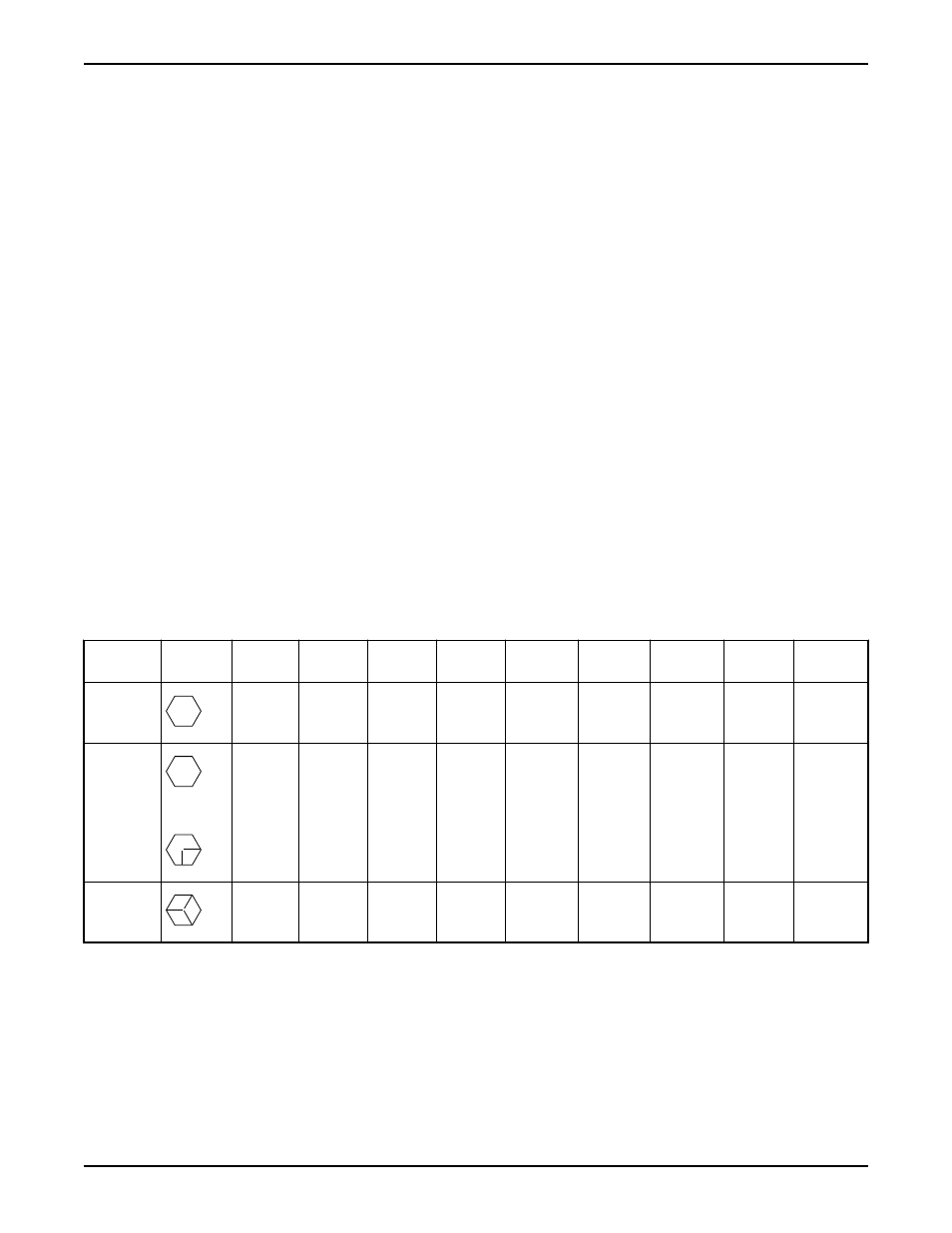

Capscrew torque values

Capscrew torque in ft-lbs (Nm)

Capscrew

type

Head

marking

1/4 in.

5/16 in.

3/8 in.

7/16 in.

1/2 in.

5/8 in.

3/4 in.

7/8 in.

1 in.

SAE grade 2

6 (8)

13 (18)

25 (34)

38 (52)

60 (81)

120 (163) 190 (258)

210 (285) 300 (407)

Brass or

stainless

steel

or

4 (5)

10 (14)

17 (23)

27 (37)

42 (57)

83 (113)

130 (176)

200 (271) 300 (407)

SAE grade 5

10 (14)

20 (27)

35 (47)

60 (81)

90 (122)

180 (244) 325 (441)

525 (712) 800 (1085)

Dealer servicing

If trouble occurs that cannot be rectified, contact your local sales and service

representative and be prepared to provide this information:

1. Complete nameplate data of pump and motor

2. Suction and discharge pipe pressure gauge readings

3. Ampere draw of the motor

4. A sketch of the pump hook-up and piping

Maintenance

Series 1535 Installation, Operation, and Maintenance Manual

21