Bell & Gossett P81553B Impeller Static Balancing Instructions User Manual

Impeller static balancing instructions, Instruction manual

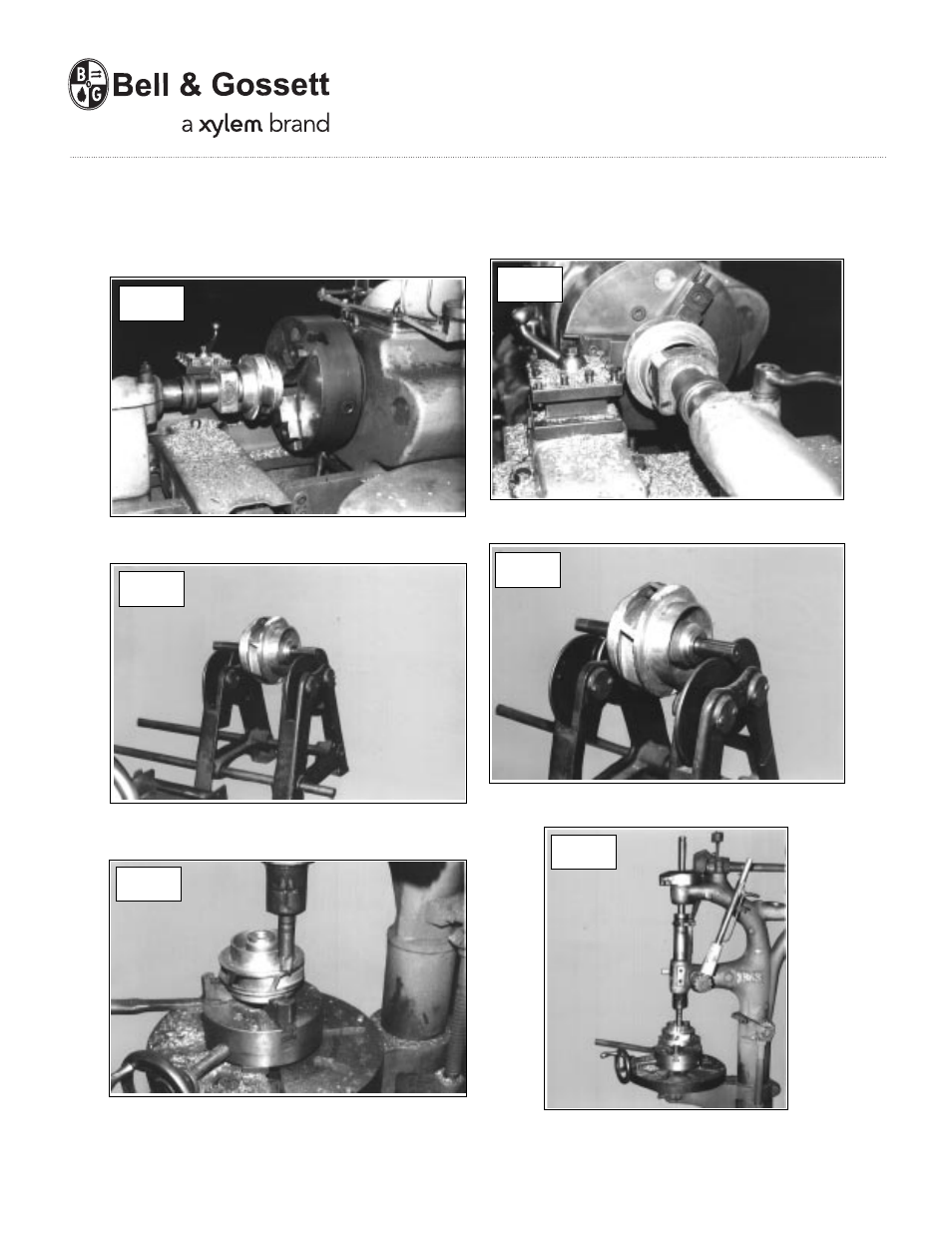

STEP NO. 2 — After impeller has been cut to size make cer-

tain that all burrs are removed. Insert mandril into impeller

and place on balancing ways. Spin the impeller lightly and

REVISION A

FIG. 1

FIG. 2

FIG. 3

FIG. 4

FIG. 5

FIG. 6

Impeller Static

Balancing Instructions

STEP NO. 1— When cutting the impeller O.D. it is suggested

that the tail stock of the lathe be utilized at act as a stabilizer

STEP NO. 3 — Place impeller in chunk on drill table. Align

flat mill cutting tool at center of imbalance point on the im-

peller wall. If the unbalanced condition is quite pronounced

make the first cut about 1/64" deep and 2" to the left and right

of the center point. This is done by moving the handle at-

tached to drill table back and forth. A continuous balance

check should be made during this operation. The impeller is

properly balanced when it remains stationary on the balance

ways on any point of it's 360° periphery.

allow to turn until it stops rocking. Make a chalk mark at the

bottom center of the impeller. This is the unbalanced point.

for holding the impeller in the chuck — Note the use of a flat

block of wood between impeller and blunt tall stock.

INSTRUCTION MANUAL

P81553B

- 10 001 247 R3 TechnoForce Package System (36 pages)

- 10 001 265R5 TechnoForce Pump Controller (76 pages)

- 10-001-275 XLS Integrated Pump Controller (57 pages)

- 10-001-278 XLS Integrated Pump Controller (44 pages)

- 176R0649C Technologic 502 Series Pump Controller (74 pages)

- 193 TECHNOVAR VARIABLE SPEED PUMP CONTROLLER AND INTEGRATED AJUSTABLE FREQUENCY DRIVE (78 pages)

- 210667C Z-4 (2 pages)

- 210668B Z-4B (6 pages)

- 211013D PSE 800 M Low Water Cut-off (20 pages)

- MM 217L Series 150S and 157S Low Water Cut-Offs/Pump Controllers (12 pages)

- Iron & Bronze Booster Pumps Series 100 (4 pages)

- P2001487 Technologic Pump Controller (93 pages)

- P2000642B i-ALERT Condition Monitor (18 pages)

- P80922A Zone Trol Pump Controller ZT-1X (4 pages)

- P80925B Zone Trol Zone Pump Controller ZT-2 (6 pages)

- S11574C Heat Transfer Package with Air Separation (8 pages)

- S11865A TECHNOLOGIC 1100 SERIES PUMP CONTROLLER (4 pages)

- 70E Multiple Pump & Control Pressure Booster Systems (28 pages)

- S12260 R4 Genuine Bell & Gossett Replacement Seal Kit (1 page)

- S12596B Technologic 350 Pump Controller (24 pages)

- S13213A MiniBooster Pumping Package (10 pages)

- S13641B Technologic 5500 Series Pump Controller (38 pages)

- S13654B Technologic 5500 Series Pump Controller (31 pages)

- S14141B 70X Multiple Pump Pressure Booster Systems (12 pages)

- S14333 Technologic 5500 Series ZoneSav Controller (38 pages)

- S14334B Technologic 5500 Series Variable Primary Pump and Valve Controller (54 pages)

- S14362C Glycol Make-up Unit (10 pages)

- S14367B Technologic Constant Speed Pump Controller (44 pages)

- 6 71 075 003A Autocirc Instant Hot Water Pump Models e3-4/BDPQC (8 pages)

- 6 71 075 110A The ecocirc auto/vario Series Pumps (4 pages)

- 6 71 075 111A Autocirc Instant Hot Water Pump Model ecocirc 23 5 ACT (8 pages)

- 6 71 075 114A Series e3 SC Solar Circulators (6 pages)

- 6 71 075 115A LS Condensate Removal Pump (6 pages)

- 6 71 075 141B ecocirc wireless Potable Hot Water Recirculation Kit (28 pages)

- A 00 091 365A Series e3 4/e3 6 Instant Hot Water Recirculating Systems (6 pages)

- A 00 091 391A Automatic Plug-In Timer for e³-4/e³-6 Circulators (2 pages)

- A91590B DB-3/4″ Differential By-Pass Valve 3/4″ x 3/4″ NPT Male Connections Operational Limits (2 pages)

- A91591 Number 98 High Capacity Air Vent 1/2″ Female NPT Connection Operational Limits (3 pages)

- AC8584D Series HSCS Base Mounted Centrifugal Pumps (32 pages)

- IM207R00 Series 3530 (24 pages)

- IM228R04 e-SV (64 pages)

- MN 414 AC Submersible Pump Motors (16 pages)

- P0002560 Wireless Module and RS-485 Module (8 pages)

- P15758C Replacing the Bearing Frame Assembly or Pump Shaft (5 pages)

- P15776H Little Red Booster Pumps (4 pages)