Replacing the seal, Remove the motor and bearing assembly, Determine the seal type – Bell & Gossett P76966E Booster Pumps 11/2HP User Manual

Page 5: Disconnect the electrical supply, Pump body diagram, Seal series 2, Seal series pd38, pd40, Rotation, Priming and starting

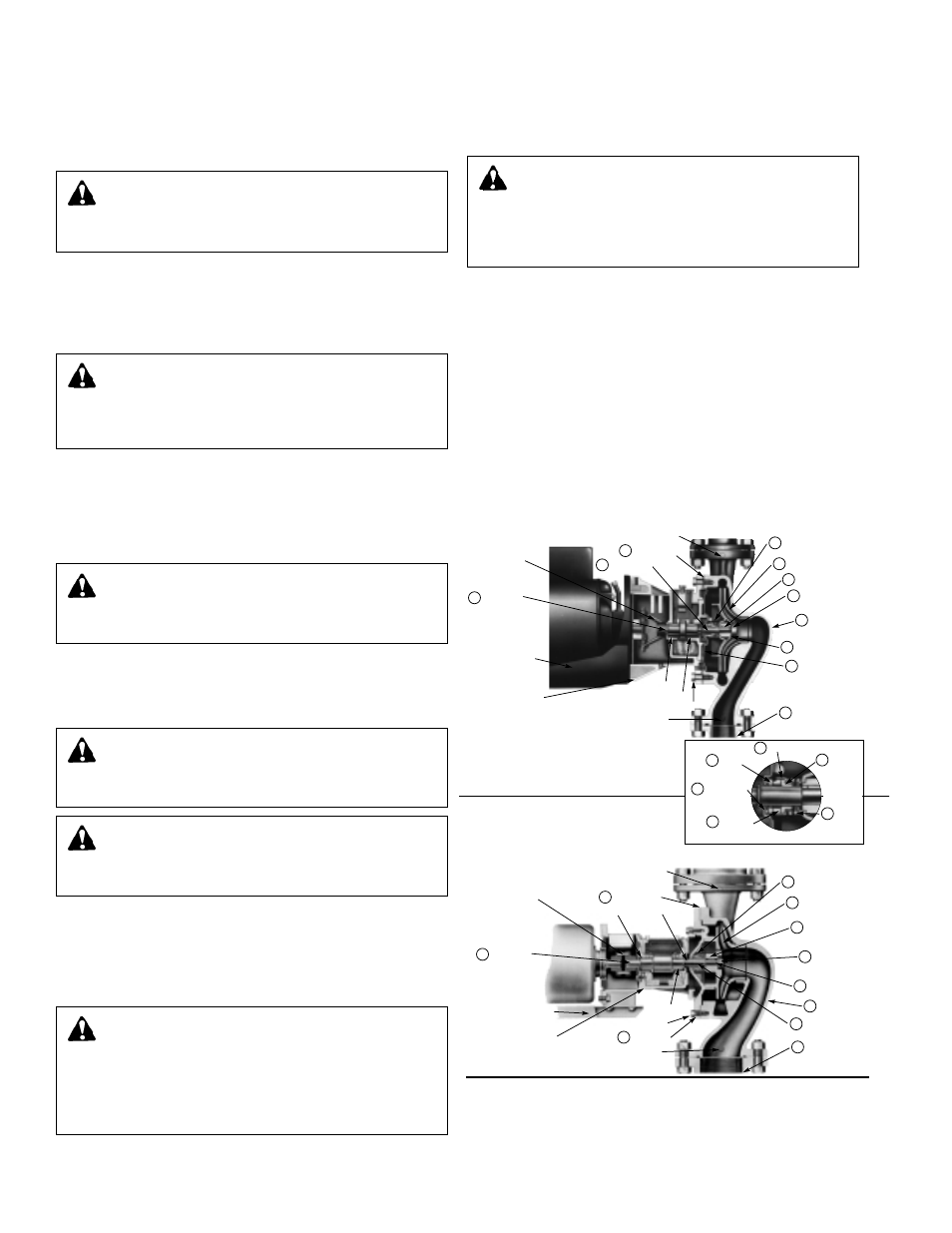

DETERMINE THE SEAL TYPE

Cut away diagrams have been provided to illustrate the compo-

nents of the booster bearing assemblies. The primary feature

distinguishing the mechanical seals of the 2

1

/

2

", LD3, HD3,

PD35, and PD37 pumps from the PD38 and PD40 is the shape

of the spring retainer which is seated between the spring and

the impeller. Refer to the following diagrams whenever seal

replacement becomes necessary.

REPLACING THE SEAL

DISCONNECT THE ELECTRICAL SUPPLY

The electrical supply must be turned off and the pump service

valves must be closed before servicing procedures begin. If

no service valves are installed, the city water supply valve

should be closed.

Loosen the conduit box cover screws and remove the cover.

Follow this procedure with the removal of the wire nuts and

flexible conduit connector.

5

REMOVE THE MOTOR AND

BEARING ASSEMBLY

WARNING: HOT WATER HAZARD

Before draining the system, allow water to cool to

100ºF max., open the drain valve (take precautions against

water damage) and leave the drain valve open until servic-

ing is complete. Failure to follow these instructions could

result in serious personal injury, death and/or property

damage.

Coupler Assembly

Rear Bearing

Front Bearing

Volute Capscrews

Suction Gage

Tapping

7

10

8

9

Pump Shaft

Motor Bracket

Assembly

Bearing Bracket

Assembly

Discharge Gage Tapping

(on side opposite)

Volute Gasket

Shaft Sleeve

Seal Assembly

4 Impeller Key

6

Impeller Lock Nut

1 Volute

5 Impeller Lock Washer

2 Face Plate

9A Seal Housing

9B Bellows

9D Spring

9C Seal Ring

9E Seat Insert

9F Seat Gasket

12 Companion Flange

(included)

3 Impeller (Enclosed)

Mechanical Seal

Front Bearing

Volute Capscrews

Suction Gage Tapping

10

Discharge Gage Tapping

(on side opposite)

Volute Gasket

11 Cover Plate

Lip Seal

Rear Bearing

Coupler Assembly

7 Pump Shaft

Motor Bracket

Assembly

Bearing Bracket

Assembly

9 Seal Assembly

4 Impeller Key

6

Impeller Lock Nut

1 Volute

5 Impeller Lock Washer

8 Shaft Sleeve

12 Companion Flange

(included)

except 2-1/2"

3 Impeller (Enclosed)

PUMP BODY DIAGRAM –

1

/

2

" SEAL

Series 2

1

/

2

", LD3, HD3, PD35, PD37

PUMP BODY DIAGRAM –

3

/

4

" SEAL

Series PD38, PD40

WARNING: ELECTRICAL SHOCK HAZARD

Disconnect and lockout the power before servicing.

Failure to follow these instructions could result in serious

personal injury or death.

WARNING: ELECTRICAL SHOCK HAZARD

Be certain the electrical power is not present at the

motor leads before continuing. Failure to follow these

instructions could result in serious personal injury or death.

WARNING: UNEXPECTED START-UP HAZARD

Disconnect and lockout power before servicing.

Failure to follow these instructions could result in serious

personal injury, death and/or property damage.

ROTATION

Pump rotation for the 2

1

/

2

", LD3 and HD3 is counterclockwise

when viewed from the back of the motor. Whereas the rota-

tion is clockwise when views from the back of the motor for

the PD35, PD37, PD38, and PD40 pumps. An arrow is provid-

ed to show the rotational direction.

PRIMING AND STARTING

Do not run B&G circulator pumps dry. Before starting, the

pump must be filled with water. Air should be vented from the

system by means of a system air vent at a high point in the

system or by an alternate method. The system must be com-

pletely vented prior to pump operation.

The pump should be started with the discharge valve closed

and the suction valve fully open. After the pump is at operat-

ing speed, the discharge valve should be opened gradually.

WARNING: HOT WATER LEAKAGE HAZARD

Pressurize the pump body slowly while checking for

leaks at all joints with gaskets. Failure to follow these

instructions could result in serious personal injury and/or

property damage.

CAUTION: SEAL DAMAGE HAZARD

Do not run the pump dry – seal damage may occur.

Failure to follow these instructions could result in moderate

personal injury and/or property damage.

The system should be drained by opening the boiler drain valve

and the vent near the top of the system. If a Flo-Control valve

is installed and there are balance valves on the returns, then

the balance valves may be closed to isolate the boiler from the

system. The Flo-Control valve will act as a check valve on the

supply and only the boiler will need to be drained. Open a vent

between the boiler and the system.

Separate the bearing assembly and motor from the pump body

by removing the volute capscrews from the bearing bracket or

cover plate (see diagrams at right).

WARNING: HIGH PRESSURE HAZARD

Pressure may be present in the pump body. This

pressure can be relieved by loosening the volute cap-

screws and shifting the bearing assembly slightly to allow

the pressurized water to escape. Failure to follow these

instructions could result in serious personal injury or death.