Xylem IM 06 Seal-less Centrifugal Canned Motor Pumps Plastic and Stainless Housing 60 Cycle (obsolete) User Manual

Page 5

5

Replacement Parts

Please provide the following information:

• Model number

• Serial number (if any)

• Part description

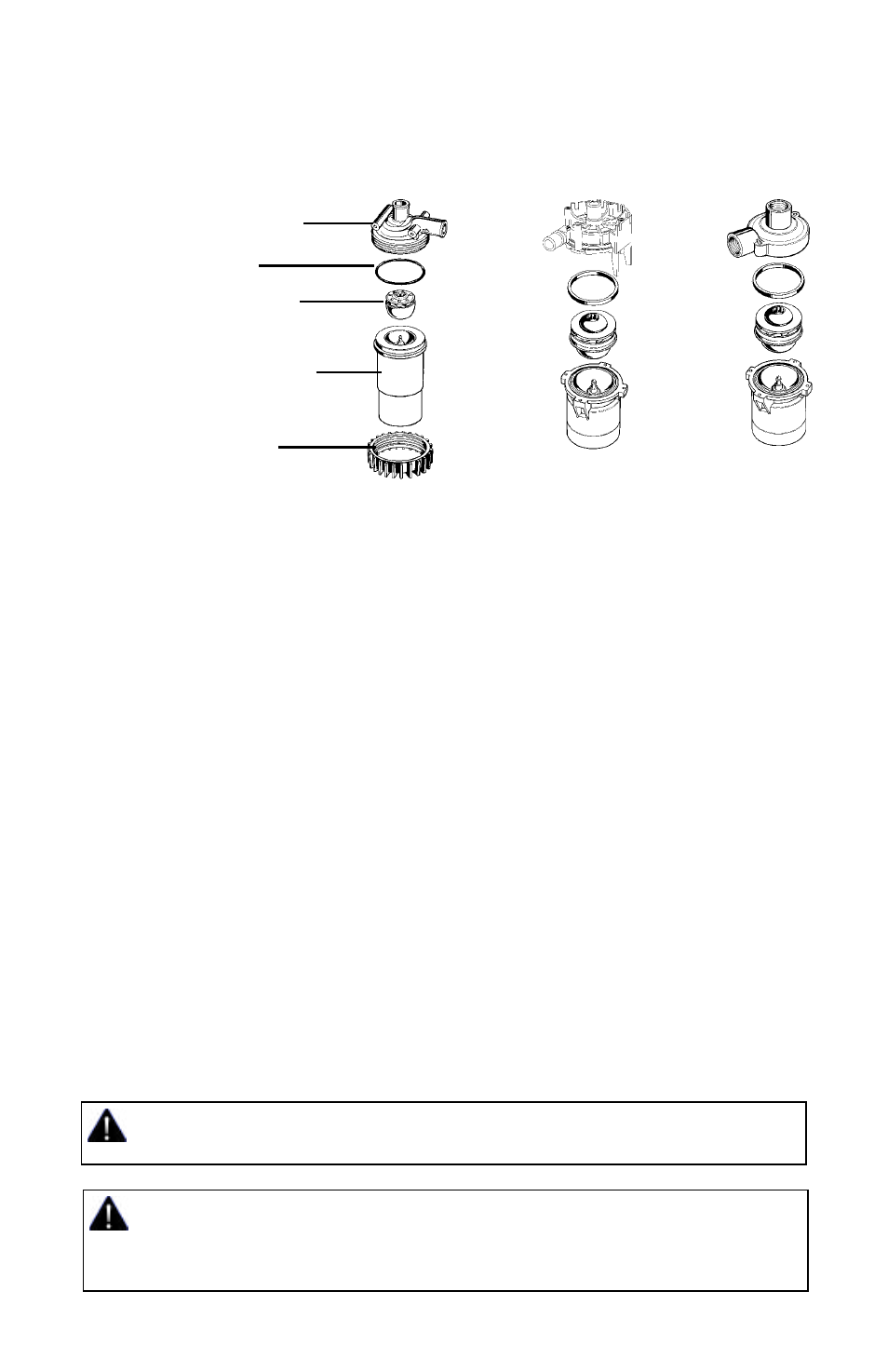

SM-909-N and SM-1212-N

SM-909-T and SM-1212-T

Pump Housing

"O" Ring

Rotor/Impeller

Assembly

Motor Assembly

Screw Ring

Trouble Shooting Chart

Symptom

Possible Causes

Corrective Action

Motor will not start or run

1. Improperly wired

1. Check motor wiring diagram

2. Blown fuse or open circuit breaker

2. Replace fuse or circuit breaker after

reason for overload has been corrected

3. Loose or broke wiring

3. Tighten connections, repair wiring

4. Foreign object in impeller

4. Disassemble pump, remove object

5. Motor shorted out

5. Replace motor

6. Dry run cutout has opened circuit

6. Allow unit to cool, restart after

reason for cutout has been

determined and corrected

Pump will not prime

1. Leak, obstruction, or kink in suction

1. Repair as necessary

line

2. Suction line closed

2. Open

3. Pump is worn

3. Replace parts

Little or no discharge

1. Housing not filled with water

1. Properly prime housing

2. Suction piping too small

2. Increase to pump inlet size or one

size larger

3. Total head too high

3. Reduce discharge head

4. Impeller plugged

4. Disassemble pump and clean impeller

5. Pump not running

5. Check motor operation

Noisy pump operation

1. Air trapped in housing

1. Check pump prime, also turn pump

on and off several times to bump

air pocket out of pump

2. Rotor bearing worn

2. Replace rotor assembly

3. Debris in housing

3. Disassemble pump and remove debris

SM-909-S

SM-1212-S

SM-303-N

WARNING: - Excessive System Pressure Hazard - The maximum working pressure of the

pump is listed on the nameplate - Do Not Exceed This Pressure. Failure to follow these

instructions could result in serious personal injury, death and/or property damage.

Safety Requirements

Mechanical Safety

WARNING: - Excessive Pressure Hazard Volumetric Expansion - The heating of water and

other fluids causes volumetric expansion. The associated forces may cause failure of system

components and the release of high temperature fluids. This can be prevented by installing

properly sized and located compression tanks and pressure relief valves. Failure to follow

these instructions could result in serious personal injury, death and/or property damage.