Wiring diagrams – Xylem IM 06 Seal-less Centrifugal Canned Motor Pumps Plastic and Stainless Housing 60 Cycle (obsolete) User Manual

Page 4

4

Wiring Diagrams

Operation

1. Completely fill the system before operating the circulator. Do not start the circulator until the

system has been filled. Make sure the isolation valves are fully open and that there is water in the

circulator.

2. Purge air from the system prior to operating the circulator. These two steps are very important. The

circulator should never be allowed to run dry. This can severely damage the circulator and will void the

warranty.

3. Operate the circulator for approximately 10 minutes to purge any remaining air in the system. It

may be necessary to open a discharge valve, port and/or fixture to ensure that the air has been purged.

The circulator should be running quietly. If a “gurgling” noise is present it may mean there is still air in

the system. Turning the circulator on and off several times will generally clear the remaining air. If this

“gurgling” noise persists, recheck the system and re-purge the air. System and circulator should now

operate quietly and efficiently.

4. Dry Run Internal Thermostat: All plastic housing model pumps are provided as standard with an

integral dry run protection thermostat that turns pump off when pump runs dry (thermostat off at

212ºF + 10ºF). If left unattended, the thermostat will automatically reset within a relatively short

amount of time when the unit cools down, thereby allowing the pump to again begin operation (at

176ºF+ 13ºF). Depending on the system conditions, many times one or two of these off/on cycles will

correct an air bound dry run condition by itself with no harm done to the pump, thereby allowing

continued trouble free operation. However, if the off/on cycling persists then measures should be taken

to correct the problems in the circulation system causing the on/off cycling. Stainless housing pumps

are not provided with a dry run thermostat.

Maintenance

1. Since the rotor/impeller unit (see exploded views) is the only moving part, its replacement and/or the

replacement of the motor is simple to accomplish.

2. After the power has been disconnected remove the screws holding the pump housing to the motor

(in the case of model SM-909 and SM-1212 units) or using a counter clockwise motion remove the

screw ring housing to motor connection on model SM-303 units.

3. Remove the “O” ring from the pump housing.

4. Remove and replace the rotor. Check to make sure that the ceramic bearing on the motor is intact

and is not chipped or otherwise damaged.

5. Replace the “O” ring with a new one and reverse the disassembly procedure to reassemble the

pump.

6. Since these units are self lubricated by the pumped fluid, they never need external lubrication.

7. Pump should be drained when subjected to freezing temperatures.

8. If provided, the suction line strainer should be cleaned at regular intervals.

Warranty

Laing recirculation pumps are warranted against defects in materials and workmanship for 24 months from

the date of manufacture (see mfg. date label on pump) or twelve (12) months from date of user purchase,

with proof of purchase, whichever is later. In order to receive warranty considerations, the product must be

returned prepaid to the company from which it was originally purchased. If the pump is found defective,

the pump will be replaced or in the case of wholesale customers, appropriate purchase credit will be issued.

Prior to returning any defective pump to Laing for warranty consideration, contact the Laing factory for

an RMA tracking number. Any claim for consequential damages resulting from a pump malfunction is not

covered by the Laing warranty. Additional warranty details are available on request.

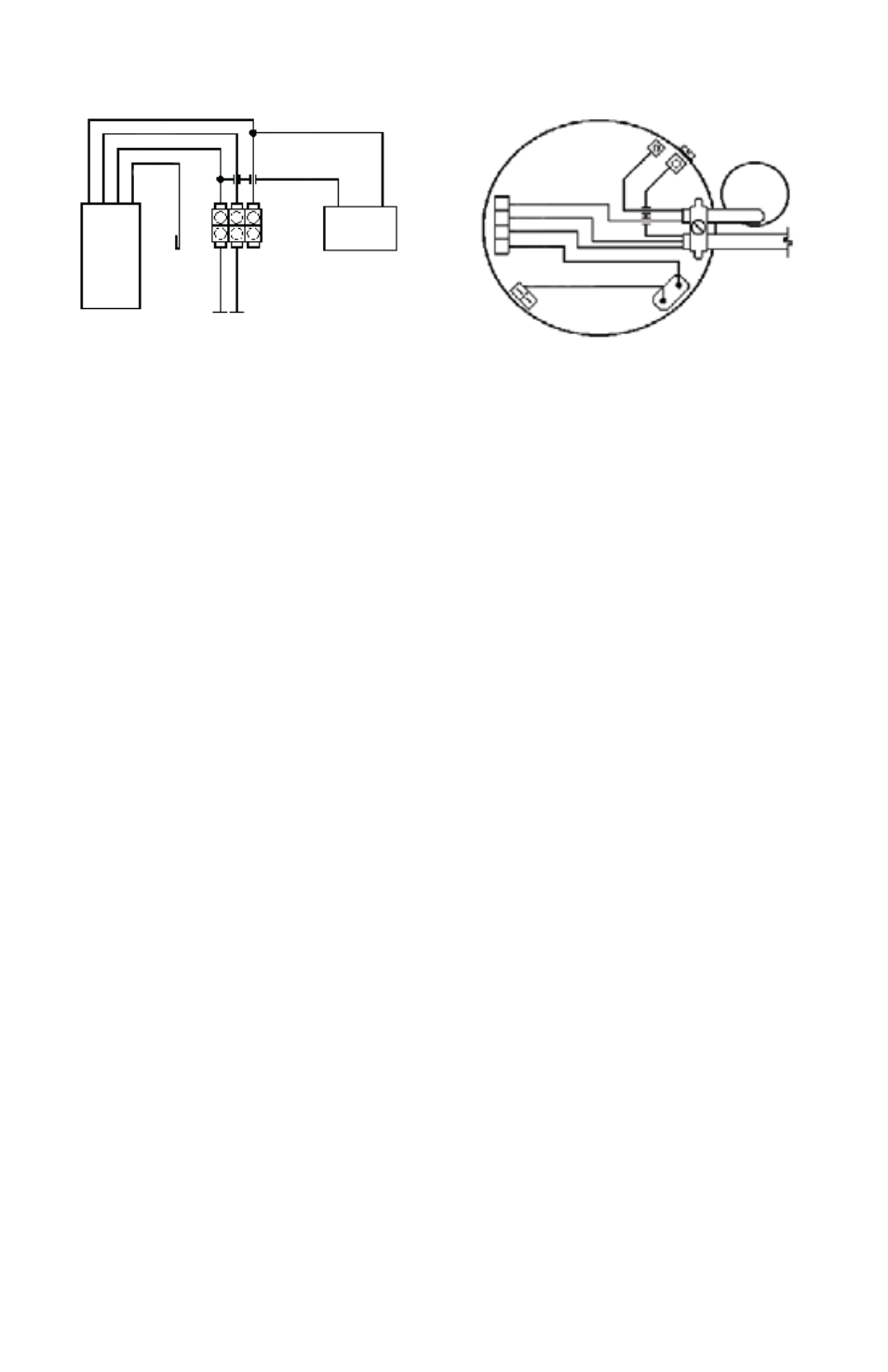

Fig. 4 - SM-909 and SM-1212 models

Brown

Black

White

Black

or White

C

B

A

I

Black or Red

TCO

Blue

Green

Ground Lug

Capacitor

TCO Settings

Open 212ºF + 10ºF

Close 176ºF +- 10ºF

Fig. 3 - SM-303 models

Black

Brown

Yellow

Red

Pump

Taped End

Black White

115v or 230v line In

Orange

Orange

Capacitor