Setting of sequence times, External sequence – Xylem 780 LIQUID SAMPLER User Manual

Page 5

5

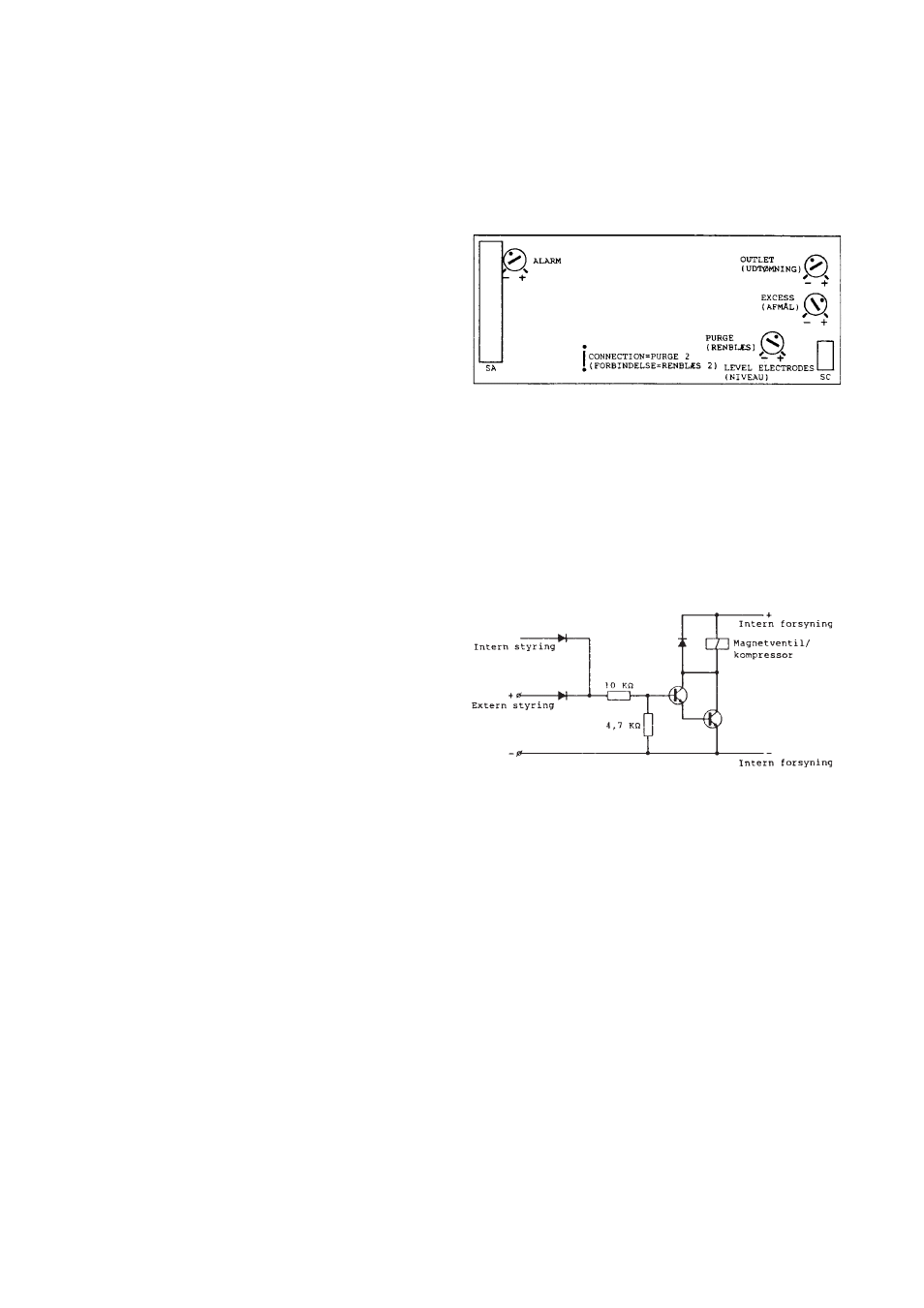

As shown in the diagram, the compressor starts when the

sampler is started. When starting, the valves are switched

out to put pressure on the sample glass, to remove any

previous sample. The purge time is determined by the

timer T1 (purge).

When time T1 has elapsed, the valves switch to create a

vacuum. The sample glass and the water will be pulled into

the sample glass, until the level electrodes are activated.

When the level electrodes have been activated, the valves

are switched over again, to put pressure on the sample

glass. Excess sample will be blown back in the sample

tube. Pressure continues until the time, determined by the

timer T2 has elapsed.

The outlet valve opens under pressure and the sample is

dropped into the sample container. The outlet valve

remains open for time T3 (purge).

It is possible to switch off the last purge by cutting off the

connection “Purge“ 2.

The sequence contains an alarm, which activates if the

sample does not contact the electrodes by a preset time

T4 (alarm). This alarm protects the sampler from continuous

cycles caused by blockage. However since the

compressor creates a 4 bar pressure, it is not very likely

that blockage will occur.

If the sampler does not succeed to activate the level

electrodes the second time before the time T4 has run out,

the sampler will stop and prevent further starts. To indicate

the alarm, the yellow alarm flashes and the alarm relay is

activated. To make the sampler start again, the alarm state

has to be reset by activating the “alarm” key.

Setting of sequence times

Setting of sequence times

Setting of sequence times

Setting of sequence times

Setting of sequence times

The sequence time is factory adjusted, to a total sample

time of approx. 2 minutes.

The 4 timers have the following time ranges:

Timer (function)

Timer (function)

Timer (function)

Timer (function)

Timer (function)

Range

Range

Range

Range

Range

Factory setting

Factory setting

Factory setting

Factory setting

Factory setting

Purge

T 1:

30 - 150 sec 30 sec

Volume

T 2:

30 - 150 sec 30 sec

adjustment

Outlet

T 3:

30 - 150 sec 30 sec

(outlet)

Alarm

T 4:

30 - 150 sec 60 sec

The sequence times are adjusted with the potentiometers

on the back of the control unit. To adjust the time, the

control unit must be removed. Switch off the sampler (ON/

OFF) key and unscrew the 4 screws, which hold the front

panel to the control panel. The control unit is integral with

the front panel. When the control unit has been removed

the sampler can be started again and the adjustment

made.

There are no dangerous voltages present at the control

unit, so it can be touched during operation. When the

desired adjustment has been made, depress (“ON/OFF”

key) to avoid short circuit during mounting, and the control

unit attachment.

External sequence

External sequence

External sequence

External sequence

External sequence

The sampler can be controlled externally, e.g. from a PLC.

When an external control is connected, it works in parallel

with the internal control, so that it is possible to select a

manual sample controlled by the internal system of the

sampler, at the same time as the external control.

The inputs are semi-conductor inputs as indicated at the

diagram.

The input signal should be not activated <0,5 V DC

Activated 5-24 V DC.