Sample cycle, Operation, Start-up – Xylem 780 LIQUID SAMPLER User Manual

Page 4

4

Sample cycle

Sample cycle

Sample cycle

Sample cycle

Sample cycle

The sample sequence is presented below:

Function:

Purge

Suction

Volume adjustment Sample pump out

Purge

(outlet to sample can)

Signal:

–––––T 1–––––

––––Level––––

–––––T 2–––––

–––––T 3–––––

––––T 1–––––

Compressor:

xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx

Pressure

xxxxxxxxxxxxxx

xxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxxx

Vacuum

xxxxxxxxxxxxxxx

Level detection

x

Outlet valve open

xxxxxxxxxxxxxx

Alarm

–––––––T 4––––––––

Operation

Operation

Operation

Operation

Operation

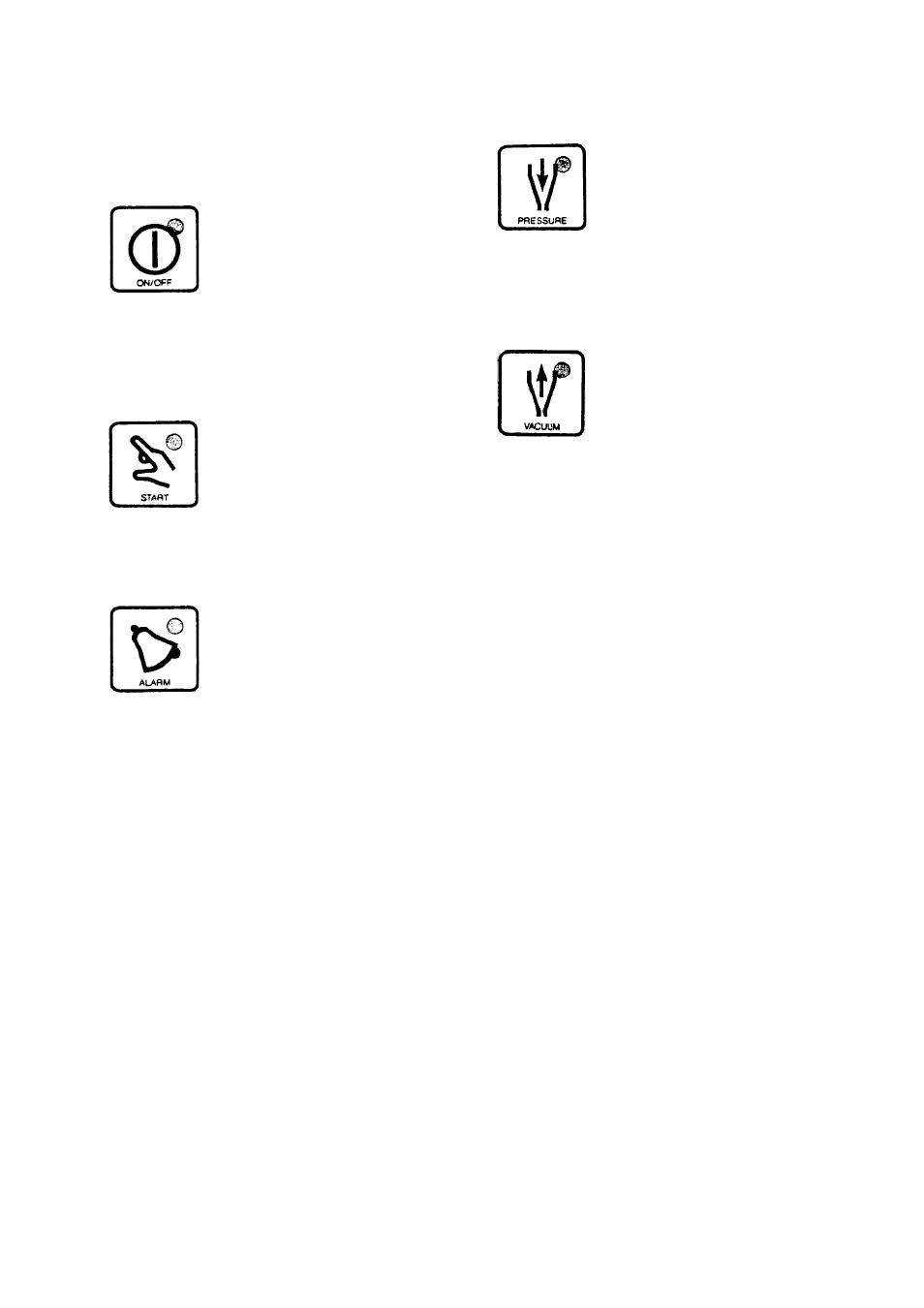

The sampler is operated on the control panel. The symbols

have the following meaning and function.

Start/stop of the sampler.

The function is an electrical memory function, so the

chosen position (start or stop) is maintained also after a

power failure. The sampler will continue taking samples or

will stop according to the previous position. The green LED

indicates that the sampler is on and ready (stand by) when

a start signal occurs.

Manuel sampling.

By depressing the start key, a sample cycle is started. This

function is always active and can be used alone or together

with an external control signal. The green LED indicates

that the sampler is in operation.

Alarm (reset).

The ALARM key resets the sample cycle.When there is an

alarm, the light diode flashes (yellow), as described in

section 9. It continues to flash until the key is activated to

reset the alarm.

Pressure indicator

This LED (green) indicates that the compressor has

pressurized the sample glass in order to:

* to purge out the previous sample from the sample tube.

* to purge out excess liquid during adjustment of the

sample volume.

* to flush the set sample volume into the sample can.

Vacuum indicator.

This LED (green) indicates that there is vacuum in the

sample glass when

* the sampler pulls up the sample in the sample glass.

Start-up

Start-up

Start-up

Start-up

Start-up

When the sampler is mounted and electrical connections

completed, the sampler is ready for start-up.

Ensure that the sample tube is immersed in the channel or

basin where the sample will be taken. Position the outlet

tube so that it reaches the sample container.

Adjust the sample volume from 20 ml – 0,5 l. The

adjustment is made by loosen the nut and pushing the

measuring pipe until the lower edge of the pipe is on the

level with the line on the sample glass, which corresponds

to the desired flow.

Connect the power supply when the measuring pipe has

been adjusted to the correct height. The ON/OFF key

activates the green diode light and the sampler is ready for

start (standby) when the “Start” key is pressed.

When the sampler is started, the green diode light will light.

During operation the compressor will be audible. The green

diode lights in the symbols for pressure and the vacuum,

indicate the internal valves are controlling the compressor.