Xylem C3V CHEMICAL METERING PUMPS User Manual

Page 3

Page 2

2.0 Specifications

Maximum Working Pressure* ..............175 psig / 12.1 bar

o o

Maximum Fluid Temperature . ..............130 F / 54 C

o o

Ambient Temperature Range . ..............14 to 115 F / -10 to 46.1 C

Output adjustment Range ...... ..............1-100% in 1% increments

Turn Down Ratio.................................... 100:1

Duty Cycle .. .............. .............. ..............Continuous

Maximum Viscosity .. .............. ..............1,000 Centipoise

Maximum Suction Lift............. ..............15 ft. water / 4.5 m water

Enclosure Rating ...... .............. ..............NEMA 4X / IP66

Power Requirements .............. ..............115v, 50/60Hz 1.5 Amp

230v, 50/60Hz 0.7Amp

Shipping Weight ....... .............. ..............29 lb. (approx.)

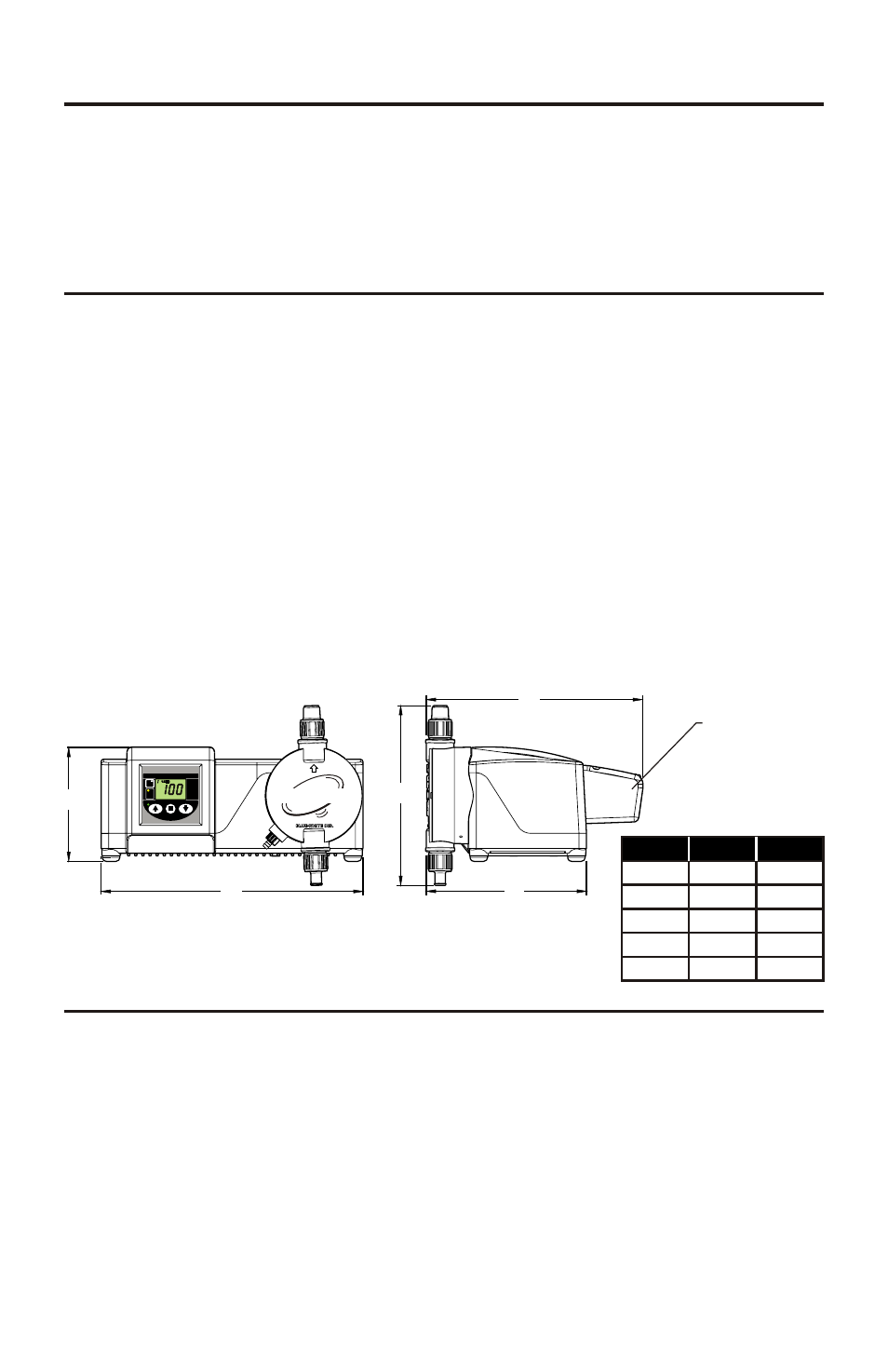

Dimensions:

Page 3

1.0 Introduction

Congratulations on purchasing the C3 Diaphragm Metering Pump. The

C3 is designed to inject chemicals into piping systems and is capable of

injecting against a high system pressure up to 175 PSI / 12.1 bar*.

C3

C3

* Depending on model selection.

CHEM-PRO

TM

tm

CHEM-PRO

C3V | Diaphragm Metering Pump

Made in the USA

MODE

PRIME

Program

Minimum

Maximum

Blue-White Ind.

IP66

NEMA 4X

Junction

Box

A

B

C

D

E

3.0 Features

Oversized PVDF double ball valves.

Operator friendly digital touch pad.

– Easy to read Back Lit LCD display

– Display percentage of motor speed

DFD, Built-in Diaphragm Failure Detection system.

Priming / degassing valve built into the pumphead

NEMA 4X and IP66 rated enclosure

Dim

Inches

mm

A

B

C

D

E

5-3/4”

13-1/8”

9”

8”

10-3/4”

144.8

332.7

228

203.2

274.3

Series

DFD

(Leak Detection)

FVS**

(Flow Verification)

Junction

Box

Pulsed* Batch

Alarm Relay

3 Amp

C3F

C3V

External Communications (input)

Output

Series Comparison:

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

P

Optional

0-10 VDC

P

P

* Also known as Frequency Mode

** Requires Micro-Flo Sensor sold separately

4-20 mA

P

P

TABLE OF CONTENTS

1.....Introduction ......................................................................................3

2.....Specifications ............. .............. .............. .............. .............. ..............3

3.....Features ....... .............. .............. .............. .............. .............. ..............3

4.....Unpacking .... .............. .............. .............. .............. .............. ..............4

5.....Installation .... .............. .............. .............. .............. .............. ..............4

5.1..Mounting location .............. .............. .............. .............. ..............4

5.2..How to install the tubing and fittings. .............. .............. ..............6

5.3..Diaphragm Failure Detection.......................................................7

5.4..Flow Verification System............................................................. 8

6.....C3F External Input/Output Signal Connection....... .............. ..............9

6.1..How to operate the C3F ............................................................10

7.....C3V External Input/Output Signal connection....... ............... .............11

7.1..How to operate the C3V .... .............. .............. .............. ..............12

7.2..Operating Mode 1 - Output adjusted manually.............. ..............13

7.3..Operating Mode 2 - 4 - 20 mA input mode.................... ..............13

7.4..Operating Mode 3 - 0 - 10 VDC Mode.................. ........ ..............16

7.5..Operating Mode 4 - Frequency Mode (Hz)..... .............. ..............18

7.6..Operating Mode 5 - Batch Mode ...... .............. .............. ..............21

8.0..Measuring the Pump’s Output - volumetric Test................................. 23

9.0..How to maintain the pump.................................................................. 24

9.1..Routine Inspection and Maintenance.......................................... 24

9.2..How to clean the pump................................................................24

Pump head and Valve exploded view drawing ...... .............. ..............25

Replacement parts drawing ...... .............. .............. .............. ..............26

Replacement parts list .............. .............. .............. .............. ..............27

Warranty information .. .............. .............. .............. .............. ..............30

Authorized service centers ....... .............. .............. .............. ..............31