Installation, Start-up – Xylem CO COM IM User Manual

Page 16

en

16

5. Installation

The product must be handled with care; impacts can cause damage without any visible external signs.

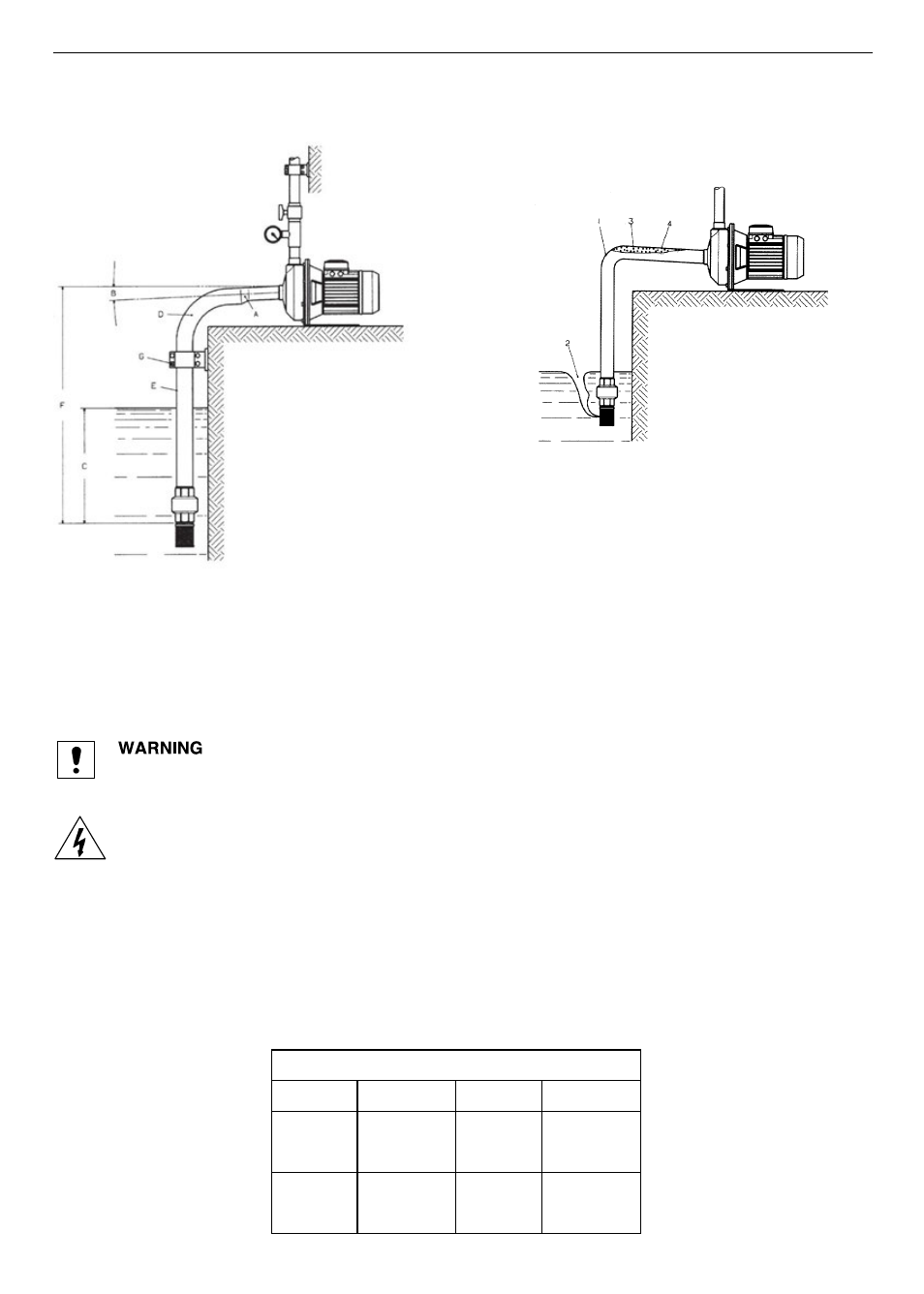

See figs. 1 and 2 for correct installation.

6. Start-up

6.1 Electrical connection

Make sure that the rated voltage corresponds to the supply voltage.

Ground the pump before making any other connection.

We recommend that a high sensitivity differential switch (30 mA) be in-

stalled as extra protection against lethal electric shocks in the event of

faulty grounding.

Connect the pump to the mains using a multiple-pole switch or other device ensuring multiple-pole discon-

nection (interruption of all the supply wires) from the mains, with a contact separation of at least 3 mm.

Remove the terminal board cover by first removing the screws.

Carry out the connections as indicated on the back of the terminal board cover, and as shown in fig. 3 for

single-phase versions and in fig. 4 for three-phase versions.

DANGER

RISK OF

ELECTRIC SHOCK

RECOMMENDED POWER CABLE SECTION

CABLE TYPE

H05VV-F

H05RN-F

H07RN-F

Single-

3x0.75 mm

3x0.75 mm

3x1 mm

phase

3x1 mm

3x1 mm

3x1.5 mm

Three-

4x0.75 mm

phase

4x1 mm

4x1.5 mm

FIGURE 2

Incorrect installation

1 = Sharp bend: high flow re-

sistance.

2 = Insufficient immersion:

sucking air.

3 = Negative gradient: air

pockets.

4 = Pipe diameter < pump

port diameter: high flow

resistance.

FIGURE 1

Correct installation

A = Eccentric reductions.

B = Positive gradient.

C = Good immersion.

D = Large bends.

E = Suction pipe diameter ≥ pump port-

diameter.

F = Suction lift depends on the pump and

installation (*).

G = The pipes should not weigh on the

pump but on separated supports.

(*) The suction lift is determined based on

liquid temperature, flow resistance and

NPSH required by the pump.