Xylem IM190 R00 Ag-Flo User Manual

Page 8

8

Wiring and Grounding

Install, ground and wire according

to local and National Electrical Code

Requirements.

Install an all leg electrical power

disconnect switch near the pump.

Disconnect and lockout electrical

power before installing or servicing

the pump.

Electrical supply MUST match

pump’s nameplate specifications. In-

correct voltage can cause fire, damage

motor and void the warranty.

Motors without built-in protection MUST be provided

with contactors and thermal overloads for single phase

motors, or starters with heaters for three phase motors.

See motor nameplate.

• Use only copper wire to motor and ground. The ground

wire MUST be at least as large as the wire to the motor.

Wires should be color coded for ease of maintenance.

• Follow motor manufacturer’s wiring diagram on the motor

nameplate or terminal cover carefully.

FAILURE TO PERMANENTLY

GROUND THE PUMP, MOTOR AND

CONTROLS BEFORE CONNECTING

TO ELECTRICAL POWER CAN CAUSE

SHOCK, BURNS OR DEATH.

Rotation

NOTICE: INCORRECT ROTATION MAY CAUSE

DAMAGE TO THE PUMP AND VOIDS

THE WARRANTY.

• Correct rotation is right-hand, CLOCKWISE when viewed

from the motor end. For frame mounted units, switch power

on and off quickly to observe rotation. On close coupled

units, remove motor end plug or cover to observe rotation.

• To reverse three phase motor rotation, interchange any two

power supply leads.

Operation

DO NOT OPERATE FRAME

MOUNTED OR SAE UNITS WITHOUT

SAFETY GUARDS IN PLACE OR

SEVERE PERSONAL INJURY MAY

RESULT.

SPLASHING OR IMMERSING OPEN

DRIP PROOF MOTORS IN FLUID

CAN CAUSE FIRE, SHOCK, BURNS OR

DEATH.

OPERATION AT OR NEAR ZERO

FLOW CAN CAUSE EXTREME HEAT,

PERSONAL INJURY OR PROPERTY

DAMAGE.

NOTICE: NO NOT RUN PUMP DRY OR SEAL

DAMAGE WILL RESULT.

• After stabilizing the system at normal operating conditions,

check the piping. If necessary, adjust the pipe supports.

• On frame-mounted units, coupling alignment may have

changed due to the temperature differential between pump

and motor. Recheck alignment following procedures and

hazard warnings in “COUPLING ALIGNMENT” section

of this manual.

Maintenance

FAILURE TO DISCONNECT AND

LOCKOUT ELECTRICAL POWER

BEFORE ATTEMPTING ANY

MAINTENANCE CAN CAUSE SHOCK,

BURNS OR DEATH.

FAILURE TO RELIEVE SYSTEM

PRESSURE AND DRAIN SYSTEM

BEFORE ATTEMPTING ANY

MAINTENANCE CAN CAUSE

PROPERTY DAMAGE, PERSONAL

INJURY OR DEATH.

IF PIPING HAZARDOUS OR TOXIC

FLUIDS, SYSTEM MUST BE FLUSHED

PRIOR TO PERFORMING SERVICE.

CloSE-CoUPlED UnITS

• Bearings are located in and are part of the motor. For lubrica-

tion information, refer to motor manufacturer’s instructions.

frAmE-moUnTED UnITS

• Bearing frame with

7

⁄

8

" Ø shaft has greased for life bearings.

No regreasing is possible or necessary.

• Bearing frames with 1

1

⁄

4

" Ø and 1

5

⁄

8

" Ø shafts and SAE drive

bearing frames should be regreased every ,000 hours or

at a three month interval, whichever occurs first. Use a #

sodium or lithium based grease. Fill until grease comes out

of relief fittings, or lip seals, then wipe off excess.

• Follow motor or engine and coupling manufacturer’s

lubrication instructions.

• Recheck alignment.

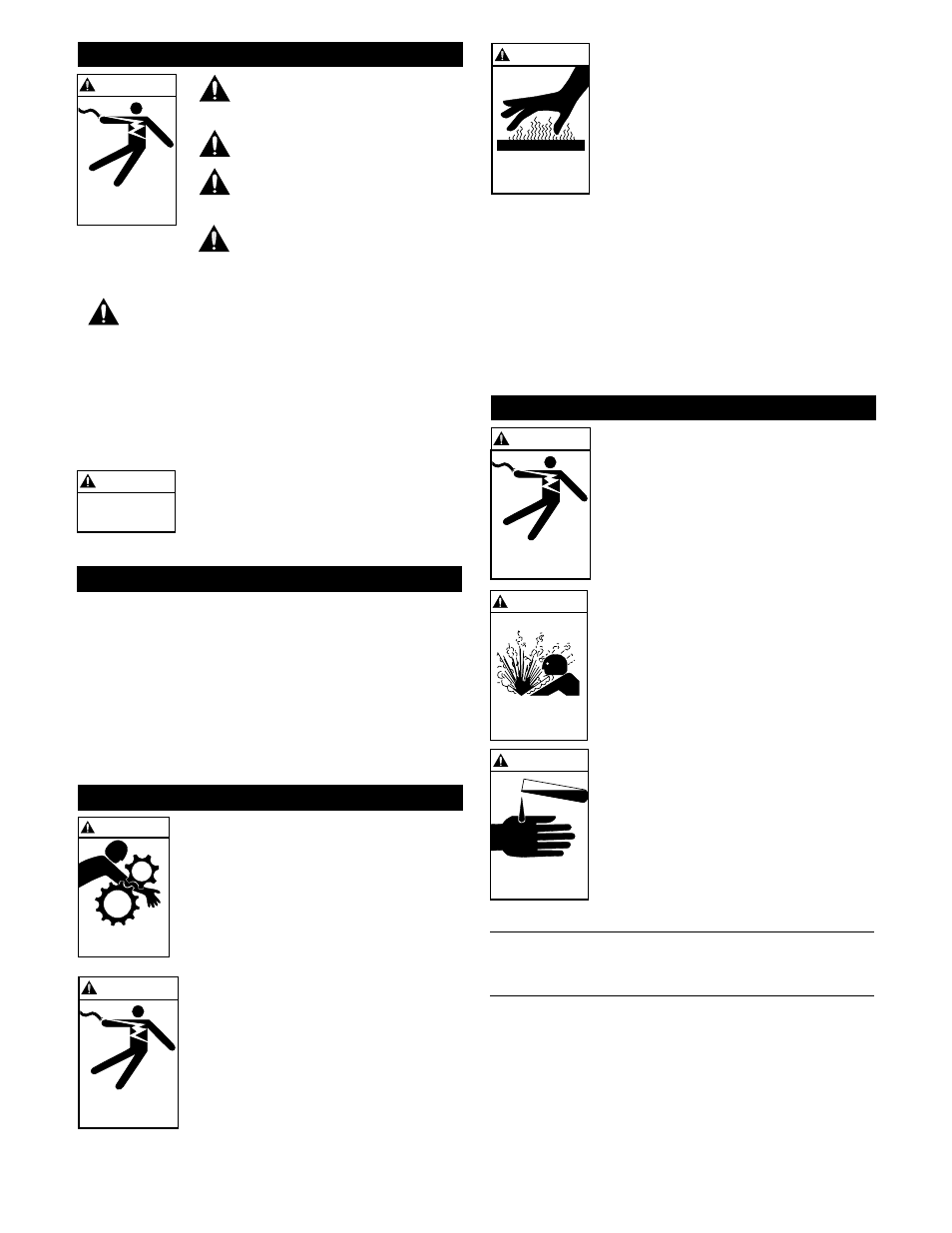

WARNING

Hazardous voltage

can shock, burn or

cause death.

WARNING

Hazardous

voltage

Hazardous machinery

can cause personal

injury or death.

WARNING

WARNING

Hazardous voltage

can shock, burn or

cause death.

Extreme heat can

cause personal injury

or property damage.

WARNING

Hazardous fluids can

cause personal injury

or property damage.

WARNING

WARNING

Hazardous voltage

can shock, burn or

cause death.

Hazardous pressure

can cause personal

injury or property

damage.

CAUTION