3 start the pump, 6 maintenance, 1 service – Xylem IM254R01 e-HM Series User Manual

Page 7: 7 troubleshooting, 1 troubleshooting table

5.3 Start the pump

1.

Start the motor.

2.

Gradually open the on-off valve on the discharge side of the

pump.

At the expected operating conditions, the pump must run

smoothly and quietly. If not, refer to

3.

If the pump does not start in correctly in 30 seconds, then do the

following:

a)

Switch off the pump.

b)

Reprime the pump.

c)

Start the pump again.

4.

Switch off and on the pump (for about 30 seconds of continuos

running) and make sure that all the trapped air is bled out by re-

peating this 2–3 times.

NOTICE:

Make sure that the pump has bled away all the trapped air. Failure to

do so can harm the product.

6 Maintenance

Precautions

Electrical Hazard:

Disconnect and lock out electrical power before installing or

servicing the unit.

WARNING:

• Maintenance and service must be performed by skilled

and qualified personnel only.

• Observe accident prevention regulations in force.

• Use suitable equipment and protection.

6.1 Service

The pump does not require any scheduled routine maintenance. If the

user wishes to schedule regular maintenance deadlines, they are de-

pendent on the type of pumped liquid and on the operating conditions

of the pump.

Contact the local sales and service representative for any requests or

information regarding routine maintenance or service.

7 Troubleshooting

Introduction

Always specify the exact pump type and identification code when re-

questing information or spare parts from the Sales and Service depart-

ment.

For other situation not mentioned in the table, refer to the Sales and

Service department.

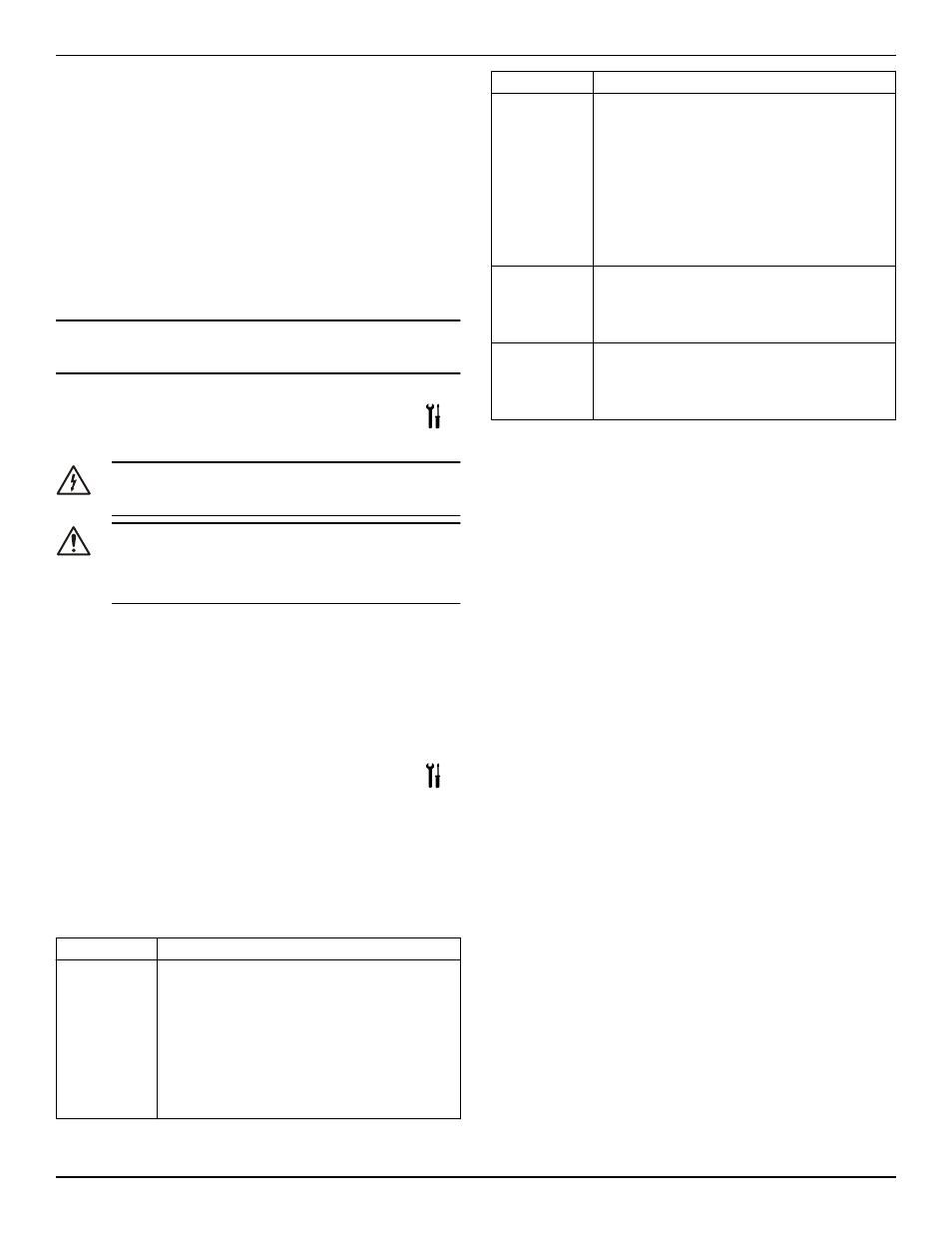

7.1 Troubleshooting table

Problem

Cause and solution

The pump does

not start.

• The thermo-overload protection in the single-

phase motor has tripped; it will automatically

reset when the motor cools down.

• Check the power supply wiring to see that the

connections are all tight

• Check to see that the circuit breaker or ground-

fault protection device has tripped. Or replace

any fuses that may have blown.

• Check to see if any protection device installed

for dry running protection has tripped or hung

up.

Problem

Cause and solution

The pump starts

up but the ther-

mal protector is

triggered after a

short time or the

fuses blow.

• The power supply cable is damaged, the motor

short circuits or thermal protector or fuses are

not suited for the motor current. Check and re-

place the components as necessary.

• The thermo-overload protection (single phase)

or of the protection device (three-phase) trips

due to excessive current input. Check the

pump working conditions.

• A phase in the power supply is missing. Check

the power supply.

• The pump is clogged with solids and the impel-

ler becomes bound. Clean the pump.

The pump starts

but does not de-

liver any liquid.

• Air is entering the suction piping, check the liq-

uid level, the tightness of the suction pipes and

the operation of the foot valve.

• The pump is not correctly primed. Repeat the

instructions in

(page 5).

The pump’s de-

livery is re-

duced.

• Check for restrictions in the piping system.

• Wrong rotation of the impeller (three-phase).

Check the direction of rotation.

• The pump is not correctly primed. Repeat the

instructions in

(page 5).

6 Maintenance

6

Model e-HM Installation, Operation, and Maintenance Manual