1 facility requirements, 1 pump location, 2 piping requirements – Xylem IM254R01 e-HM Series User Manual

Page 5: 2 electrical requirements, 1 pump location 4.1.2 piping requirements, 4 installation

4 Installation

Precautions

WARNING:

• Observe accident prevention regulations in force.

• Use suitable equipment and protection.

• Always refer to the local and/or national regulations,

legislation, and codes in force regarding the selection of

the installation site, plumbing, and power connections.

4.1 Facility requirements

4.1.1 Pump location

DANGER:

Do not use this unit in environments that may contain flam-

mable/explosive or chemically aggressive gases or powders.

Guidelines

Observe the following guidelines regarding the location of the prod-

uct:

• Make sure that no obstructions hinder the normal flow of the cool-

ing air that is delivered by the motor fan.

• Make sure that the installation area is protected from any fluid

leaks, or flooding.

• If possible, place the pump slightly higher than the floor level.

• The ambient temperature must be between -30°C (-22°F) and

+40°C (+104°F) unless otherwise specified in the data plate.

• The relative humidity of the ambient air must be less than 50% at

+40°C (+104°F).

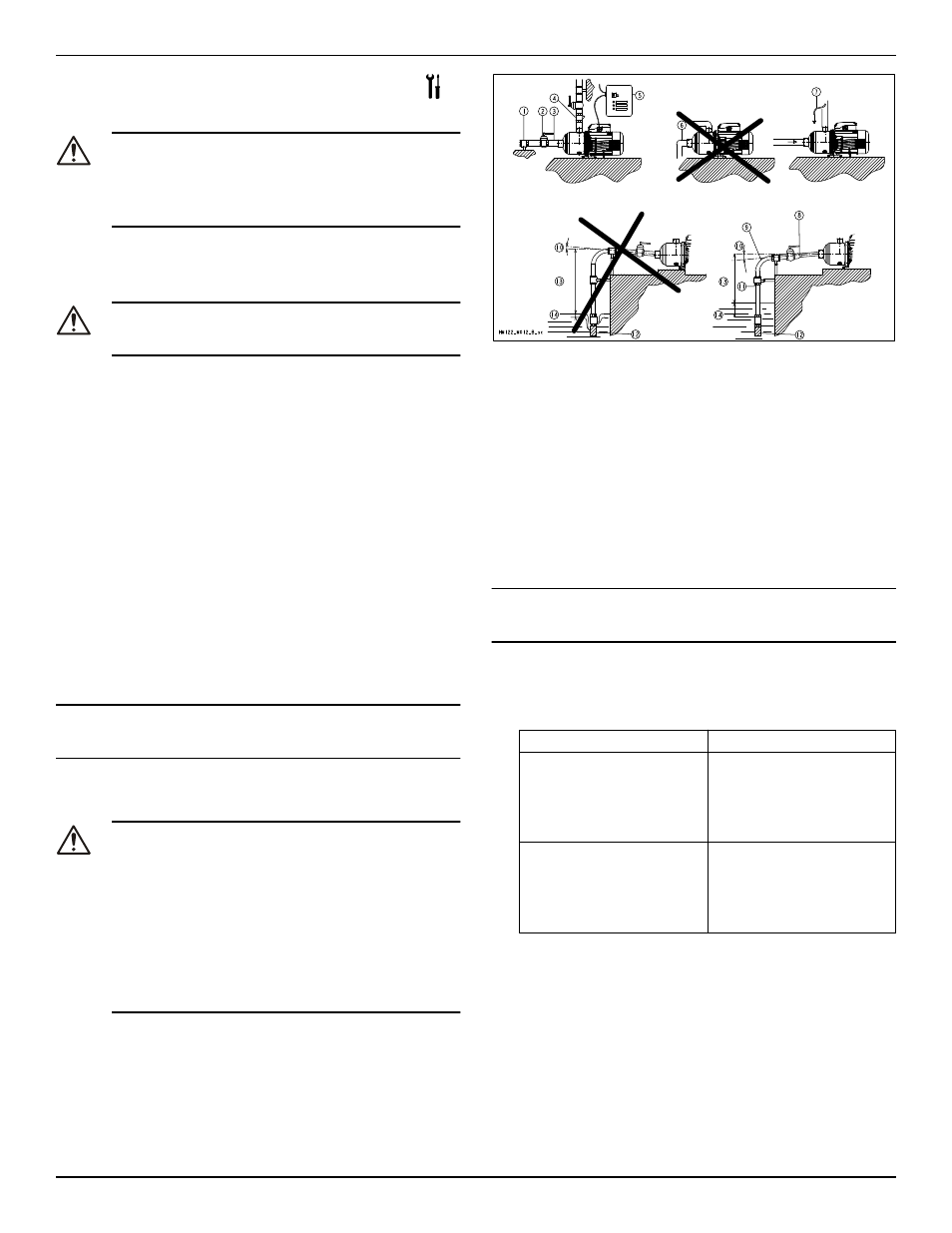

Installation above liquid source (suction lift)

The theoretical maximum suction height of any pump is 34 ft. In prac-

tice, this is not achieved due to the following conditions affecting the

suction capability of the pump:

• Temperature of the liquid

• Elevation above the sea level (in an open system)

• System pressure (in a closed system)

• Resistance of the pipes

• Own intrinsic flow resistance of the pump

• Height differences

NOTICE:

Do not exceed the pumps suction capacity as this could cause cavita-

tion and damage the pump.

4.1.2 Piping requirements

Precautions

WARNING:

• Use pipes suited to the maximum working pressure of

the pump. Failure to do so can cause the system to rup-

ture, with the risk of injury.

• Make sure that all connections are performed by quali-

fied installation technicians and in compliance with the

regulations in force.

• Do not use the on-off valve on the discharge side in the

closed position for more than a few seconds. If the

pump must operate with the discharge side closed for

more than a few seconds, a bypass circuit must be instal-

led to prevent overheating of the water inside the

pump.

Piping checklist

• Pipes and valves must be correctly sized.

• Pipe work must not transmit any load or torque to pump flanges.

4.2 Electrical requirements

• The local regulations in force overrule these specified require-

ments. In the case of fire fighting systems (hydrants and/or sprin-

klers), check the local regulations.

Electrical connection checklist

Check that the following requirements are met:

• The electrical leads are protected from high temperature, vibra-

tions, and collisions.

• The power supply line is provided with:

• A short-circuit protection device

• A main disconnect switch.

The electrical control panel checklist

NOTICE:

The control panel must match the ratings of the electric pump. Improp-

er combinations could fail to guarantee the protection of the motor.

Check that the following requirements are met:

• The control panel must protect the motor against overload and

short-circuit.

• Install the correct overload protection (thermal relay or motor pro-

tector).

Pump Type

Protection

Single phase standard electric

pump up to 3 HP

• Built-in automatic reset

thermal-overload protec-

tion

• Short circuit protection

(must be supplied by the

installer)

Three-phase electric pump

• Thermal protection (must

be supplied by the instal-

ler)

• Short circuit protection

(must be supplied by the

installer)

• The control panel must be equipped with a dry-running protec-

tion system to which a pressure switch, float switch, sensors, or

other suitable device is connected.

• The following devices are recommended for use on the suction

side of the pump:

• When the liquid is pumped from a water system, use a pres-

sure switch.

• When the liquid is pumped from a storage tank or reservoir,

use a float switch or sensors.

• When thermal relays are used, relays that are sensitive to phase

failure are recommended.

The motor checklist

Use cable according to rules with 3 leads (2+earth/ground) for single

phase versions and with 4 leads (3+earth/ground) for three-phase ver-

sion.

4 Installation

4

Model e-HM Installation, Operation, and Maintenance Manual