Controller dimensions 9: troubleshooting, Continued) – Xylem IM156 R06 1AB2 & 2AB2, Aquavar ABII Variable Speed Pump Controller User Manual

Page 11

11

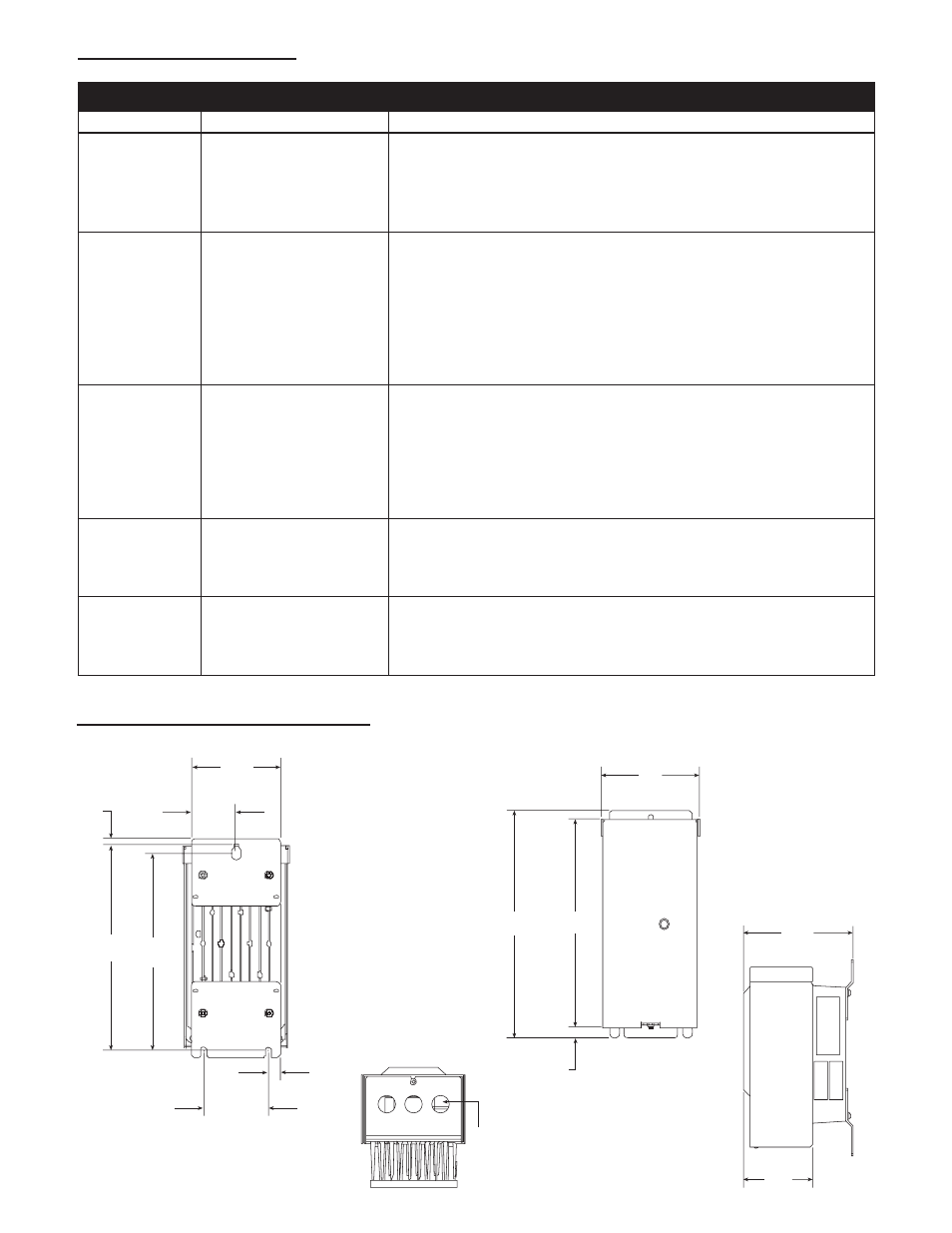

10: CONTROLLER DIMENSIONS

9: TROUBLESHOOTING

(continued)

10: CONTROLLER DIMENSIONS

9: TROUBLESHOOTING

RED LIGHT CODES

Indicator Code Status

Description

5 Blinks

Short Circuit

Check wiring for shorting phase to phase and phase to ground. Turn

power to controller off and wait 5 minutes. Remove controller

access panel. Disconnect motor leads marked T1, T2, and T3. Measure

resistance between all motor leads using an ohmmeter. NOTE: Motor

winding resistance is typically 2 to 10 OHMS depending on motor.

6 Blinks

Ground Fault

Check wiring for shorting phase to ground. Turn power to controller

off and wait 5 minutes. Remove controller access panel. Disconnect

motor leads T1, T2, T3, and Ground from controller. Measure

resistance between all motor leads and ground using a Megohmmeter.

Connect one Megohmmeter lead to any one of the motor leads and

the other to ground lead. Set Megohmmeter to 500V DC output.

Resistance readings less than 500,000 ohms or 0.5 Megohms indicate

a damaged motor.

7 Blinks

High Temperature

This fault is caused by a high temperature inside of the controller. The

controller will shut off when the temperature inside the controller

reaches 158º F (70º C). The controller will turn back on when the

temperature inside the controller reaches 150º F (65.5º C). Avoid

installing the controller where ambient temperatures exceed 104º F

(40º C). Avoid installing the controller where it is exposed to direct

sunlight.

8 Blinks

Over Voltage

Measure input voltage using an AC voltmeter. Connect the positive

and negative leads to L1 and L2 on the Aquavar ABII controller. Verify

line input voltage is not greater than 264 VAC for 1AB2 and 2AB2

controllers and 132VAC for 1151AB2.

9 Blinks

Motor Overload

This fault is indicated when the current supplied to the motor exceeds

the Motor Overload Setting on the Aquavar ABII controller. Refer to

Section 7, Setting the Motor Overload DIP Switches for details. If

switches are set according to Section 7, check motor.

(135.36)

5.33

(259.08)

10.20

(237.06)

9.33

(12.07)

.48

(157.90)

6.22

(99.06)

3.90

(114.30)

4.50

(57.15)

2.25

(8.38)

.33

(242.04)

9.53

(232.56)

9.16

(81.28)

3.20

(16.51)

.65

1

∨

2

”

Liquid

Tight

(135.36)

5.33

(259.08)

10.20

(237.06)

9.33

(12.07)

.48

(157.90)

6.22

(99.06)

3.90

(114.30)

4.50

(57.15)

2.25

(8.38)

.33

(242.04)

9.53

(232.56)

9.16

(81.28)

3.20

(16.51)

.65

1

∨

2

”

Liquid

Tight

(135.36)

5.33

(259.08)

10.20

(237.06)

9.33

(12.07)

.48

(157.90)

6.22

(99.06)

3.90

(114.30)

4.50

(57.15)

2.25

(8.38)

.33

(242.04)

9.53

(232.56)

9.16

(81.28)

3.20

(16.51)

.65

1

∨

2

”

Liquid

Tight

(135.36)

5.33

(259.08)

10.20

(237.06)

9.33

(12.07)

.48

(157.90)

6.22

(99.06)

3.90

(114.30)

4.50

(57.15)

2.25

(8.38)

.33

(242.04)

9.53

(232.56)

9.16

(81.28)

3.20

(16.51)

.65

1

∨

2

”

Liquid

Tight